Description

What are Slide Retainers?

Slide Retainers are used to hold the side cores/sliders during mold opening and component ejection. Slide Retainers are generally used to hold slides in a mold when the mold design requires a moving core. Helps to facilitate accurate and proper movement within the mold.

Strong, durable construction Pivot area is designed for high strength and long life elongated jaw area provides overtravel clearance gives added flexibility during set up to reduce possibilities of damage.

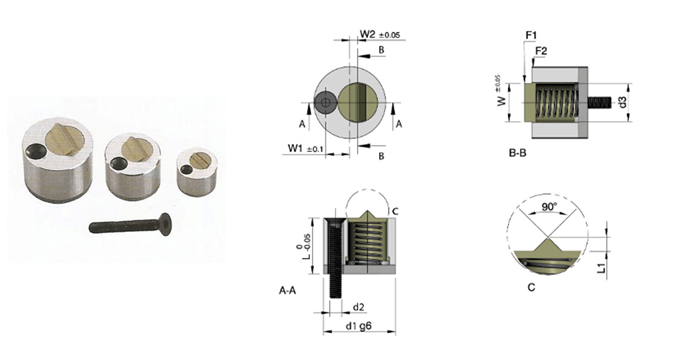

Slide Retainer Drawing

Slide Retainer Specifications

| Model Number | d1 | d2 | d3 | L | L1 | W | W1 | W2 | Max. Holding Wt.Kgs |

| DGMF-062/13 | 13 | M2×16 | 7 | 10 | 1.0 | 6.6 | 4.3 | 1.4 | 3.4 |

| DGMF-062/18 | 18 | M3×20 | 10 | 14 | 1.8 | 9.6 | 6.0 | 2.0 | 4.2 |

| DGMF-062/27 | 27 | M4×25 | 15 | 21 | 2.8 | 14.4 | 9.0 | 3.0 | 9.2 |

Features & Usage of Slide Retainers

- High-strength tool alloy construction provides durable production life – components resist wear over many slide cycles.

- Compact – fits with mold base No protruding hardware on mold base exterior ideal for confined space large, flat surface provides greater slide retention and positive locking easily machined into existing slides Mounts with simple socket head-cap screws

- Optimum corrosion protection

- Service temperature up to 100 ℃

- Holding force of 3.4 – 9.2 kg

- The sliding retainer can be replaced on the machine

- Compact size, inside mounted spring, easy to install

- When designing and processing the mold, the degree of installing screw and mold head must be 90 °

- Should custom own design and process the V-groove on the slide according to the actual conditions.

The adjustable slide retainer is a sturdy and compact product able to guarantee high loading performance and high longevity. The locking is performed with rollers aimed at minimizing wear, the special design allows for setting the locking position.

Slide Retainers are used to hold slides in a mold when the mold design requires a moving core. It helps facilitate accurate and proper movement within the mold. And it is available various, each with its own characteristics and applications.

DGMF Mold Clamps Co., Ltd supplies the ejector pins, straight ejector pins, ejector sleeve pins, ejector blades, shoulder ejector pins, guide pins, core pins, angle pins, dowel pins, guide bushing, A-type sprue bushing, B-type sprue bushing, C-type sprue bushing, small gate sprue bushing, big gate sprue bushing, support pillars, slide retainer, taper block set, round tapered interlocks, side lock, etc.

Contact the DGMF team for the injection mold components specification, inventory, pricing.

Reviews

There are no reviews yet.