Description

What are Parting Line Sequence Control Two-stage Ejectors?

Two-stage ejectors are used where two ejection sequences are required, for example, to demould undercuts with inclined cores, or to ensure that slides do not collide with ejector pins.

Two-stage Ejectors Product Description

The two-stage ejecting structure is a structure in which it is possible to carry out the ejecting operation twice at the time of ejecting the molded article from the core.

Although ejection is done only once in the usual injection mold, since in the case of the two-stage ejecting structure it is possible inside the mold to carry out ejection two times with a time gap between them, this is a mechanism that is very convenient in cases in which the molded item cannot be taken out the mold with only one ejecting operation.

A two-stage ejector, It is offered a variety of individual possibilities for reliable motion control and molding during the injection molding process. All two-stage ejectors are now available with DLC-coated functional surfaces.

The high layer hardness and low friction values of the coated two-stage ejectors significantly improve the life of the mold and thus makes a major contribution to increasing productivity and lowering costs in the production process.

The Z169/Z1691/Z1692/Z1695… two-stage ejectors are the classic solution for activating a stripper plate. Automatic and precise holding and opening mechanisms allow independent movement between two plates. The accurate movements guarantee consistent part quality without compromise.

Two-stage ejector features

- Interlocking mechanism design, safe and reliable;

- This secondary ejection mechanism is simple in structure and convenient in installation and needs a minimal installation space;

- Important parts are made of SKD11 materials and adopt the high-quality heat treatment process, being more wear-resistant;

- The surface with coating treatment, higher wear resistance create a longer lifespan.

It is convenient for installing processing machinery interlocking design so that it is safe and reliable. The installation stroke needs to be calculated accurately. Otherwise, the product is likely to be damaged. Select appropriate specifications according to the load requirement of the die.

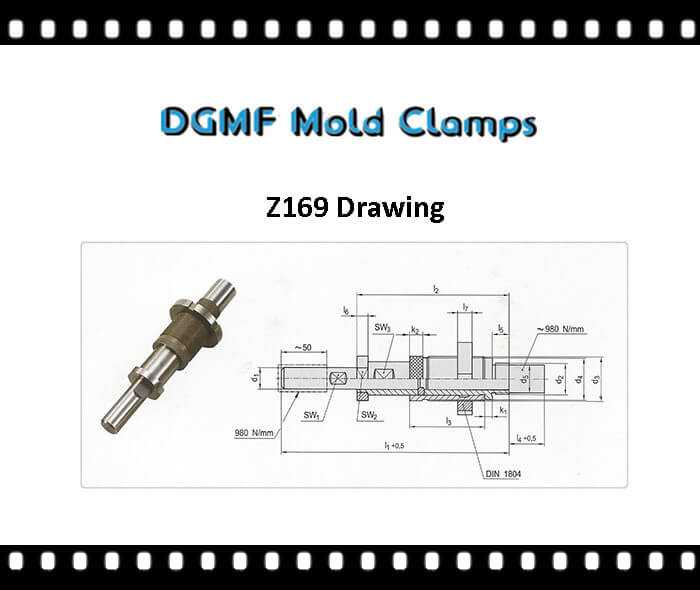

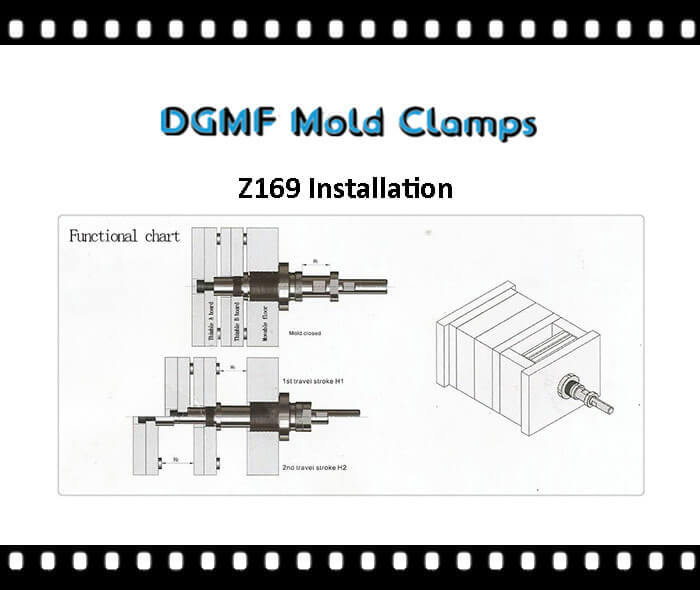

The Z169 two-stage ejector is the classic solution for activating a stripper plate. Automatic and precise holding and opening mechanisms allow independent movement between two plates. The accurate movements guarantee consistent part quality without compromise.

Z169 two-stage ejector drawing

Z169 two-stage ejector installation

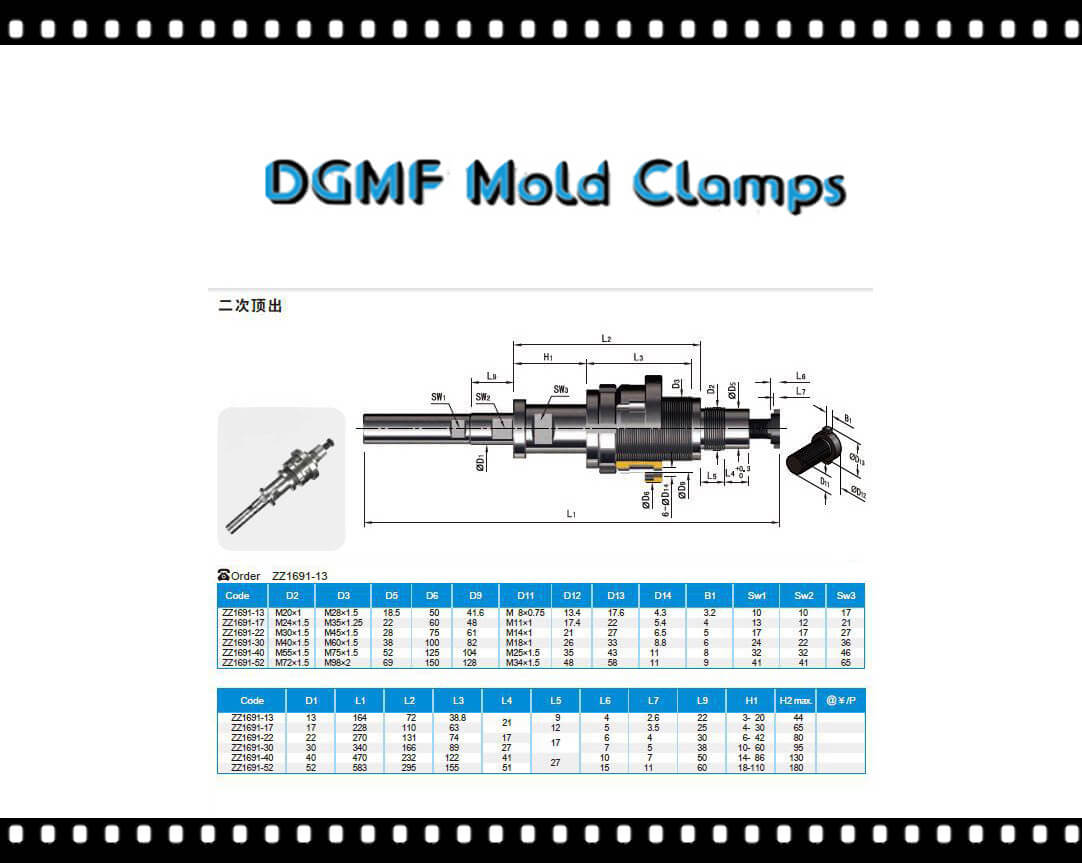

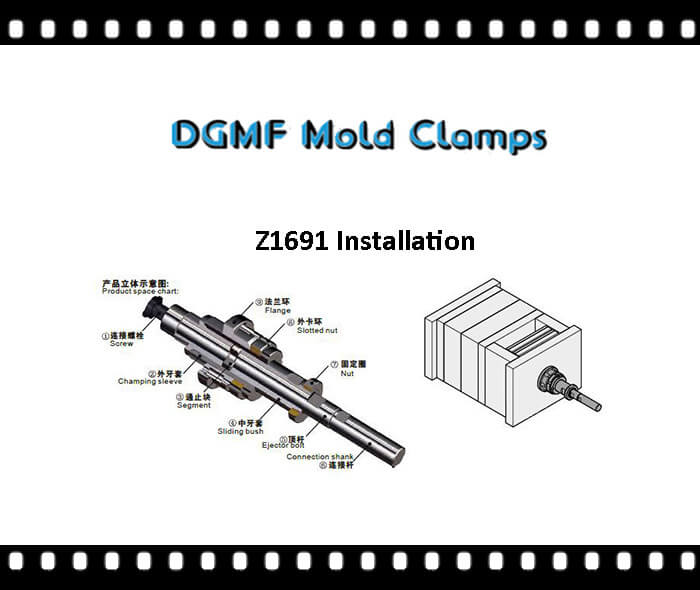

The Z1691 two-stage ejector is an extension of the classic Z169. It offers the same motions plus improved locking. One advantage is the simple assembly through the integrated flange attachment. Specially designed centering rings allow particularly smooth axial motion and ensure high service life. Available with a shaft diameter of 13-52 mm, it can be used in small to large molds.

Z1691 two-stage ejector drawing and specifications

Z1691 two-stage ejector installation

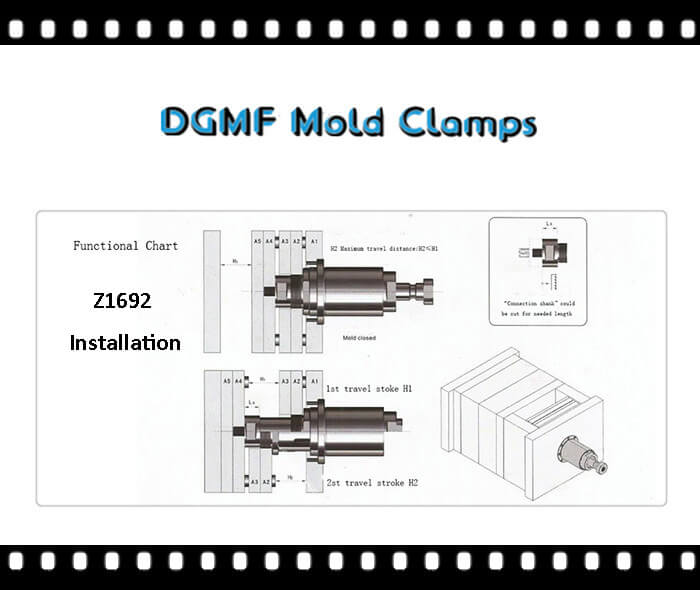

The Z1692 two-stage ejector is developed for demoulding processes in which the first and second stroke has to function completely separately from one another. The stroke can be subsequently modified or it can be preset to your requirements directly ex works.

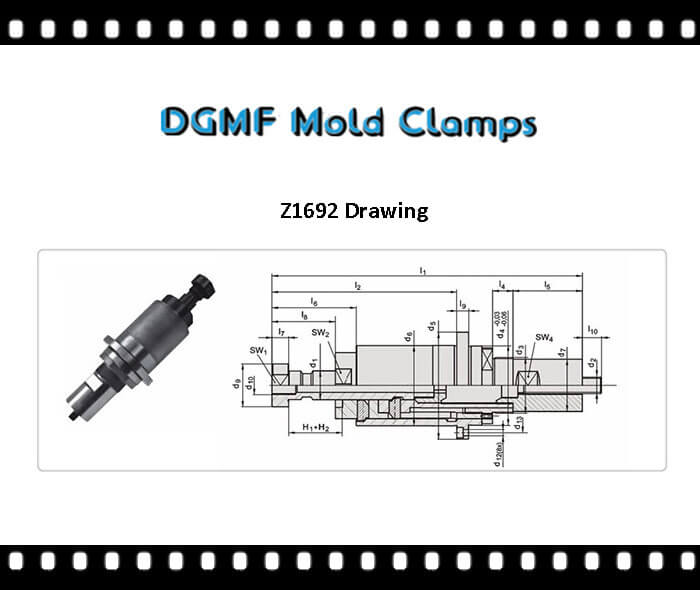

Z1692 two-stage ejector drawing

Z1692 two-stage ejector installation

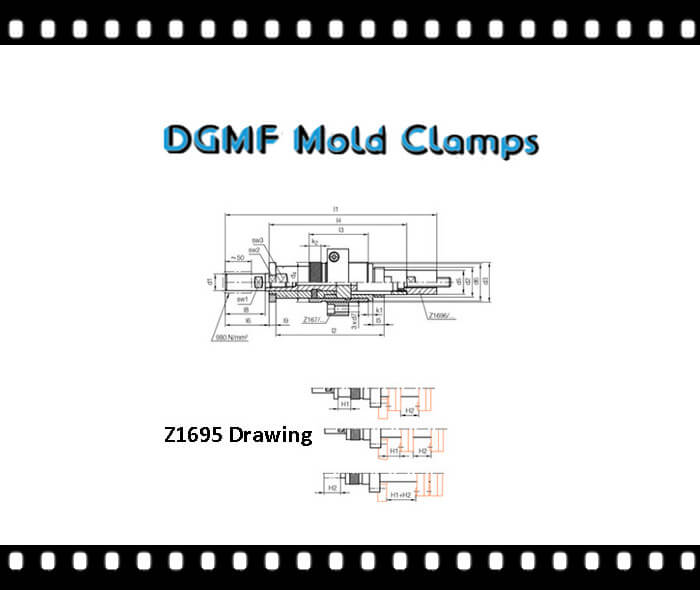

Z1695 two-stage ejector is suitable for controlled plate movement during demoulding with an inclined sliding carriage. The precision movement of the first stage prevents stressing of the part. Subsequent opening of the rear stage allows the ejection of the part at a precise predefined position.

Z1695 two-stage ejector drawing

Designed for applications in which a central ejector cannot be used.

Because of the lubricant-free functional surfaces, the maintenance intervals are longer. Applications in medical and food technology are possible, as are parts that subsequently have to be painted or lacquered.

The high layer hardness and low friction values of the coated two-stage ejectors significantly improve the life of the mold and thus makes a major contribution to increasing productivity and lowering costs in the production process.

Reviews

There are no reviews yet.