Description

What are Oilless Slide Core Guide Units?

The Oilless Slide Core Guide Units are the AISI DIN JIS Standard Mold Components Oilless Slide Core Guide Units Square Pin Type Used For Plastic Molds Supplied By DGMF Mold Clamps Co., Ltd.

Contact the DGMF sales team or engineering team for more details on the Oilless Slide Core Guide Units such as Oilless Slide Core Guide Units specifications, Oilless Slide Core Guide Units pricing, and Oilless Slide Core Guide Units inventory.

What is the function of the Oilless Slide Core Guide Units?

The function of the oilless slide core guide units squares pin type of the plastic mold is to fix the lifter pin and connect the lifter pin to the ejector pin plate.

Lifter pin self-lubricating oilless slide core guide unit assembly is simple in design, economical and practical, and takes up space. It can be directly installed on the lifter pin fixed slide core guide unit mechanism or fixed with a pressure bar.

The center slider can swing a 0-20° tilt angle, which is very easy to install, The self-lubricating support plate reduces friction, and the inner hole can be non-standard precision customized round or square holes to suit round or square ejector rods.

The mold liter pin oilless slide guide unit assembly adopts a non-lubricating design slider, which allows the lifter pin to move smoothly when opening and closing the mold. It is mainly suitable for the occasion of the core pulling of the inner side of a large mold.

How do install the oilless slide core guide units?

It is installed on the ejector plate and formed by the lifter pin. The convex and concave core on the inner side of the plastic part is pushed out obliquely to complete the core pulling.

Because the slide guide unit of the lifter ejector pin can swing freely within 0-20°, the wear and damage of the guide rail and the sliding plate can be reduced by adjusting the center of gravity.

Oilless Slide Core Guide Units Product Description

The oilless slide core guide unit is mainly suitable for the inner side core pulling occasion of a large mold, the movable core assembly mounted on the push plate, and the core of the concave and convex shape of the inner side of the molded plastic part is obliquely ejected by the oblique push rod, and the core is completed.

The oilless slide core guide unit device comprises three parts: a lifter pin holder, slide plate, and a parallel key, and is installed in the mold lifter pin seat.

The whole set of products is mounted on the ejector push plate of the mold, and the lifter pushrod is required to be formed, after molding, During the process of pushing out the push plate, the inner core of the molded plastic part is ejected in a predetermined manner by self-lubricating, so that the rubber piece can be smoothly detached.

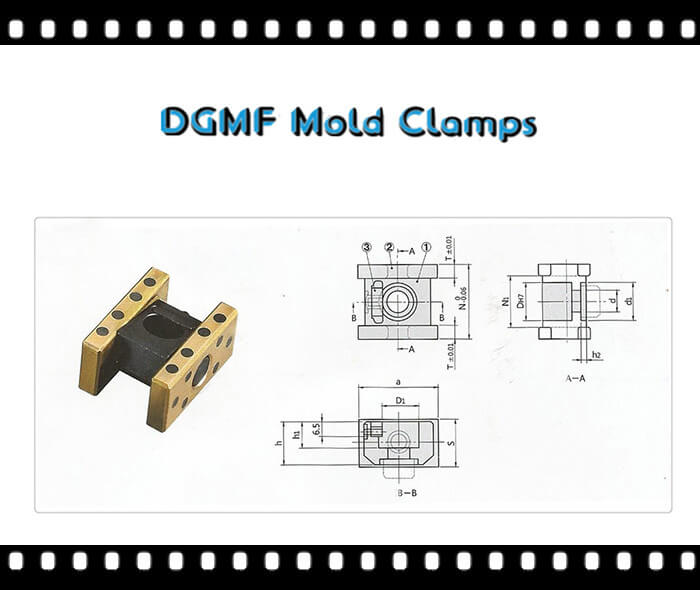

Oilless Slide Core Guide Units Drawing

Oilless Slide Core Guide Units Product details:

- The product design is simple and easy to install.

- Because the anti-flip structure is arranged on the rotating shaft bearing portion of the lifter guide pin fixing seat, the lifter guiding rod is easier to install.

- Due to the compact structure of the lifter guide rod fixing seat, interference with the mold during the tilting movement is avoided.

- The installation angle of the self-lubricating plate is 0° ∽ 10°, which can be selected according to the unevenness of the inner side of the molded product.

- The solid lubricant is inlaid on all three sides of the self-lubricating plate. It is excellent in wear resistance, load resistance, and sinter resistance. It can maintain stable performance for a long time without grease. However, in order to prevent initial jamming, it is recommended to apply grease when installing.

Reviews

There are no reviews yet.