Description

What are Core Pins?

Core pins are used in the plastic injection mold and die casting mold. They are fixed elements used to create a void providing the desired shape in the injection molded or die-casted part. It is often easier to machine a core pin as a separate element and add it to the A-side or B-side as needed.

Steel core pins are sometimes used in aluminum molds to create tall, thin cores that might be too fragile if machined out of the bulk aluminum of the injection mold. The core pins are also used for part ejection from a die-cast mold.

Note:

A-Side of a core pin is sometimes called the “cavity” it is the half of the mold that usually creates the exterior of a cosmetic part. The A-side usually does not have moving parts built into it.

B-Side is sometimes called the core. it is the half of the mold where ejectors, side-action cams, and the other complex components are located. On a cosmetic part, the B-side usually creates the inside of the part.

Plastic injection mold around these core pins to form small holes, or use them to perforate parts. They have a flat head to fit into a counterbored hole. Core pins can be machined to fit your application. They’re precision-ground to tight tolerances. Made of M2 tool steel, these pins are wear-resistant and stay sharp at high temperatures.

Core Pins Information:

| Place of Origin: | Guangdong, China |

| Model Number: | DGMF-011 |

| Product Name: | Standard Core Pin |

| Application: | Plastic Injection Mold and Die Casting Mold. |

| Product Material: | SKD51 |

| Color: | Metal Color |

| Surface treatment: | Vakuum + Nitride |

| Hardness: | HRC58-60 |

| Tolerance: | ±0.01mm |

| Surface Work: | Polished |

| Standard: | MISUMI,HASCO,DME,JIS,AISI,ASTM,GB,DIN |

| Processing: | Close to Ra0.2 |

| Packaging Type: | Box |

| Packaging Size: | AS per requirement |

| Minimum Order Quantity: | 1 Piece |

| Price: | Negotiable |

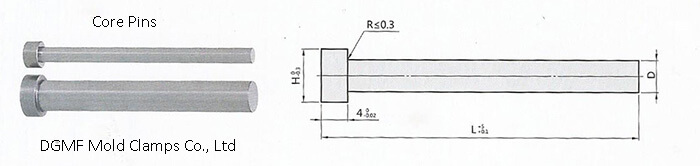

The Core Pin’s Drawing:

The Core Pin’s Specifications:

| Model Number | D | H | T | L |

| DG MF-011-A

(SHK51)

DG MF-011-A (SKD61)

|

1.0 | 3 | 4 | 20≤L≤150 |

| 1.1 | ||||

| 1.2 | ||||

| 1.3 | ||||

| 1.4 | ||||

| 1.5 | ||||

| 1.6 | 4 | |||

| 1.7 | ||||

| 1.8 | ||||

| 1.9 | ||||

| 2.0 | ||||

| 2.5 | 5 | |||

| 3.0 | 6 | |||

| 3.5 | 7 | |||

| 4.0 | ||||

| 4.5 | 8 | |||

| 5.0 | ||||

| 5.5 | 9 | |||

| 6.0 | ||||

| 6.5 | 10 | |||

| 7.0 | ||||

| 8.0 | 11 | |||

| 10 | 15 | |||

| 13 | 18 | |||

| 16 | 21 |

TO ORDER SPECIFY: Moder Number-D-L

DGMF Mold Clamps Co., Ltd supplies the ejector pins, straight ejector pins, ejector sleeve pins, ejector blades, shoulder ejector pins, guide pins, core pins, angle pins, dowel pins, guide bushing, A-type sprue bushing, B-type sprue bushing, C-type sprue bushing, small gate sprue bushing, big gate sprue bushing, etc.

DGMF Mold Clamps Co., Ltd is the mold clamps Manufacturer in China, also provide injection mold components, die press components, machine tools, fasteners for your best choice.

Contact the DGMF team for the injection mold components specification, inventory, pricing.

Reviews

There are no reviews yet.