Description

CNC Vise Double Station

The CNC vise double station is a vise dedicated to CNC machine tools that can clamp 2 workpieces at the same time. Double station vise is also called dual station vise, used on CNC machine, can clamp two workpieces at the same time.

Heavy-duty milling machine two-way angle solid vise CNC dual station precision machine vise 4 inches 6 inches direct sales.

CNC Vise Features

1. It can be used in a variety of functions and can be used on CNC machinery to clamp two work objects at the same time;

2. Angle-fixed design, the mouth of the tiger is naturally locked when clamping the work;

3. It can clamp workpieces of different shapes at the same time, with up to 5 clamping methods;

4. The CNC Vise body is precisely machined with high toughness ductile iron;

5. The angle-fixed clamping structure can prevent the workpiece from floating up;

6. It has two clamping stations, which can clamp two workpieces of equal or unequal size, and can also clamp two identical workpieces with different machining surfaces in different clamping positions at the same time;

7. The parallelism of the two jaws and the perpendicularity of the two jaws to the guide rail surface ≤0.025mm/100mm;

8. CNC Vise jaws can be used as a single unit, or multiple units can be used side by side;

9. Widely used in machining centers, CNC milling machines, and precision machine tools.

Components of the double station CNC vise

1. Screw

It is made of high-quality materials and precision turning; it is durable, and the surface is anti-wear and anti-corrosion.

2. Bearing seat

The bearing seat is used as the moving point of the screw rod to improve work efficiency, and also make the screw rod smoother, smoother, and more durable.

3. Detachable jaw

The jaws are all flat design, after grinding; and adopt a detachable design to protect the plier’s body, easy to replace.

4. Middle fixed block

The fixed clamp block in the center realizes clamping two workpieces at the same time, improving work efficiency, and can also be disassembled for use, so as to realize the purpose of clamping a single large workpiece with a large opening.

5. Adjust the screw

When clamping workpieces of the same size, tighten the screws as shown in the figure; when clamping workpieces of different sizes, loosen the hexagon socket screws to achieve clamping of workpieces of different sizes.

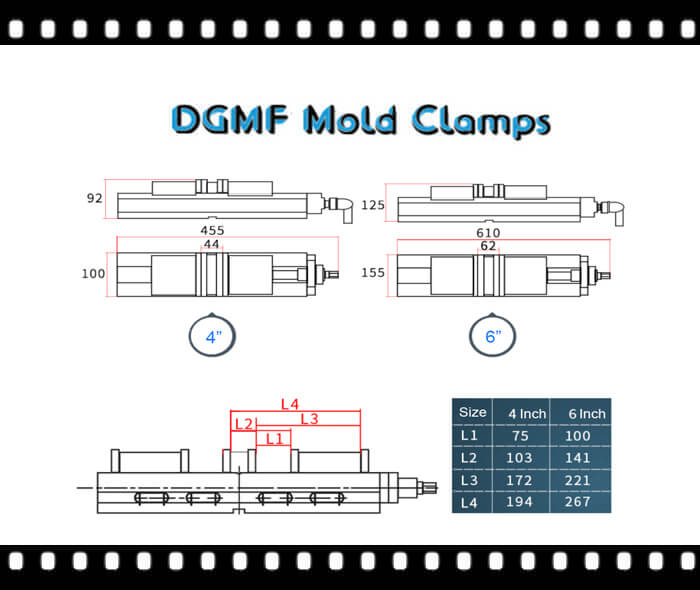

CNC Vise Double Station Vise Specifications

| Size | Maximum opening | Jaw height | Jaw width | LxWxH | Maximum clamping force | Positioning key width | Weight |

| 4″ | 75 | 31 | 100 | 390x100x92 | 19KN | 14 | 15.5KG |

| 6″ | 100 | 45 | 160 | 510x160x125 | 29KN | 18 | 36KG |

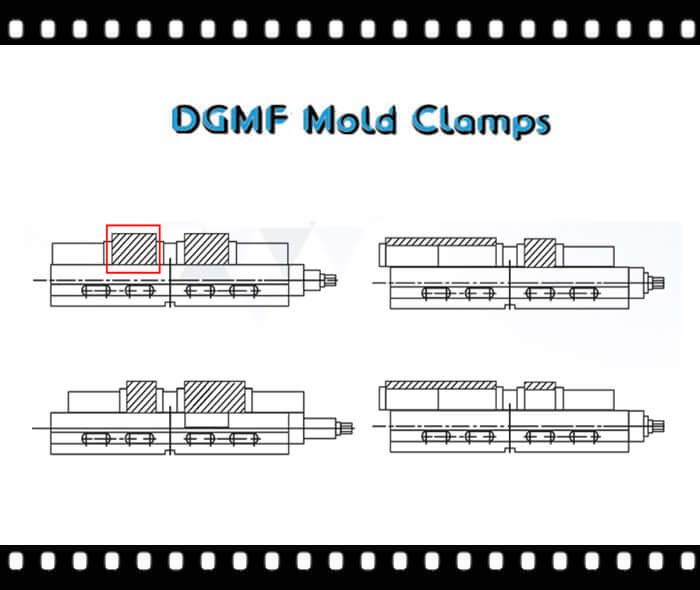

Multiple CNC Vise clamping methods

Can clamp the same size workpiece or different size workpiece.

The two-way vise has two clamping stations, which can clamp two workpieces of the same size or two different sizes at the same time.

It can also clamp two identical workpieces with different machining surfaces in different clamping positions at the same time.

The middle fixed block can also be disassembled to realize the clamping with a large opening degree, and multiple units can be used side by side to improve equipment utilization.

Wrong approach:

When the workpiece is clamped, the workpiece is on one side of the jaws, which will cause uneven force on the jaws, which will cause the jaws to be tilted and force, and the accuracy will decrease. In severe cases, the flat-nose pliers may be damaged.

The correct way:

When clamping the workpiece, the workpiece is clamped under the 1/2 position of the jaw or in the middle position. At this time, the jaw is evenly stressed and can be used normally.

Wrong approach:

When the workpiece is clamped, the workpiece is above the 1/2 position of the jaws, which will cause uneven force on the jaws, which will cause the jaws to be tilted and force, and the accuracy will decrease. In severe cases, the flat-nose pliers may be damaged.

The correct way:

When clamping the workpiece, the workpiece is under the 1/2 position of the jaw or clamped at the bottom position. At this time, the jaw is evenly stressed and can be used normally.

CNC vise Use attention

Please use the product in the correct way

It is not allowed to knock and use crowbar casing during use, which will affect its accuracy and life. If it is knocked, a crowbar and the CNC machine vise will no longer be guaranteed. In case of insufficient clamping force, you can contact customer service to replace a larger product.

Please follow the correct operation method when clamping the workpiece, otherwise, the flat-nose pliers will no longer be guaranteed to be cleaned and oiled on time to prevent rust. Pay attention to frequent maintenance to extend the service life.

DGMF Mold Clamps Co., Ltd supplies the machine mounts, vises of the machine tools series.

Reviews

There are no reviews yet.