What are the differences between two-platen mold and three-platen mold?

After the read, you will learn about what is the difference between the two-platen mold and three-platen mold.

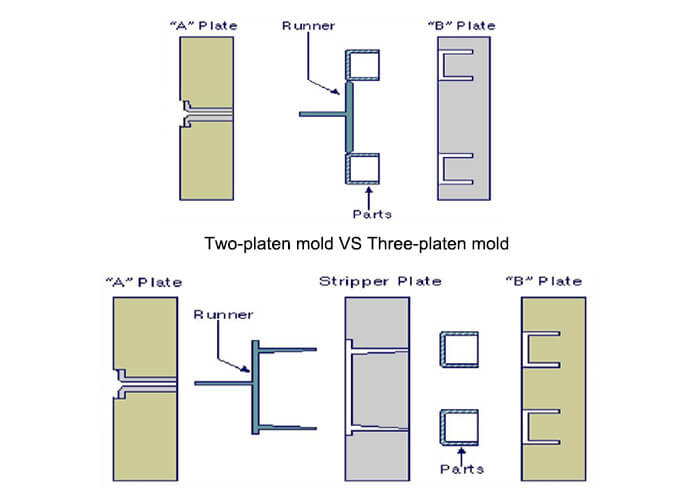

The three-plate mold refers to a set of mold embryos composed of A-plate, B-plate, and nozzle stripping board; a two-plate membrane means that the membrane embryo is composed of A-plate and B-plate.

Three-plate membrane structure description

The runner side nails are matched with the guide pin, and then the front mold is corrected (the guide runner plate panel A). The runner side nails are placed on the entire rear mold without a guide pin, and the templates are all empty.

Therefore, the runner side nails only guide the front mold, and the front and rear molds are guided by the guide pins. The guide pin guides the rear mold and the front mold (guides the B plate and the A plate pusher). There is a meson under the nozzle side nail to prevent it. If the tie rod is finished, the meson under the nozzle side nail can also be limited.

Generally, the default situation is Bottom, the outside is the runner side nail, the inside is the guide pin guide bushing, of course, there is also the outside is the guide bushing guide pin, and the inside is the runner side nail. At this time, you should pay special attention when setting the mold material.

The difference between two-platen mold and three-platen mold

- The three-plate molds generally have guide pins on the front mold. The two-plate mold is the general name of the large nozzle mold, two plates (A plate, B plate). The three-plate mold generally refers to the fine nozzle mold, and the three plates (A plate, B plate, and stripping plate) have one more stripping plate.

- The cost of the three-plate mold is relatively high, the injection pressure is higher, and the nozzle recovery cost is increased.

- The structure of the two-platen mold is relatively simple.

- The pouring point is different, the two plates are inconvenient to directly enter the product, and the direct entry is the large nozzle, which is inconvenient to remove at the time. The gate marks are more obvious. With three plates, the gate can be designed in an ideal position for comparison and convenience, and the gate will fall off by itself, leaving little traces.

- Two-platen molds are more widely used. Two-plate molds are used for latent injection, horn injection, and direct injection.

- The molds are mostly straight gates, fan gates, etc., which are easy to fill and are often used for large parts; three-plate molds are mostly pointed gates, which are often used for multi-point injection, which is conducive to the separation of nozzles. There are more small parts. Choose this type, it can also be used for large parts. Three-plate molds generally have guide pins on the front mold.

The biggest difference between the two-plate mold and the three-plate mold is that the three-plate mold has an extra stripping board. Generally speaking, the two-plate mold is the most common type of mold. The three-plate mold is because the product appearance requirements are high, and the obvious glue point cannot be seen. It eliminates the process of cutting the nozzle.

Therefore, it is also called a detailed mouth mold or a dispensing mouth mold, but its injection pressure is much higher than that of a two-plate mold. The material loss of the material head is large.

From the perspective of the mold structure, the guide pillars of the three-platen mold are all on the front mold, and the guide pillars of the two-platen mold are on the back mold. From the point of view of usage, products with a small nozzle inlet method use a three-plate mold; while a large nozzle inlet method uses a two-plate mold for plastic products.

The use of two-plate mold and three-plate mold

The feed material of the large gate can be ejected together with the product, and a two-plate mold can be used. The glue of the point gate is separated from the product when the mold is opened, and a sliding plate for the gate material to escape must be installed in the front mold, and a three-plate mold must be used.

You may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept