Mold-making processing

What is Mold-making?

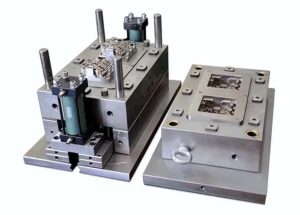

Mold-making refers to the processing of molding and blanking tools, as well as shear dies and die-cutting dies.

Typically, a mold consists of an upper and lower die. The steel plate is placed between the upper and lower molds to achieve the molding of the material under the action of the press, and when the press is opened, the workpiece determined by the shape of the mold is obtained or the corresponding waste material is removed. Workpieces as small as an electronic connector or as large as an automobile dashboard can be molded with a die.

A progressive die is a set of dies that can automatically move the processed workpiece from one station to another and get the molded part at the last station. Mold machining processes include cutting dies, blanking dies, composite dies, extrusion dies, four-slide dies, progressive dies, stamping dies, die-cutting dies, and so on.

What are the types of mold-making processing?

Common types of mold-making are the following 6 kinds.

- Metal stamping die: continuous die, single punch die, composite die, stretching die

- Plastic molding die: injection mold, extrusion mold, plastic absorption mold

- Die casting mold

- Forging mold

- Powder metallurgy mold

- 6. Rubber mold

Mold-making processing flow

Open material: front mold material, rear mold material, insert material, line material, oblique top material;

Frame opening: front mold frame, rear mold frame;

Roughening: front mold cavity roughening, rear mold cavity roughening, mold parting line roughening;

Copper male: copper male for front mold, copper male for rear mold, copper male for clearing angle of parting mold line;

Wire cutting: insert mold parting line, copper male, oblique top pillow position;

Computer gong: fine gong mold parting line, fine gong rear mold core;

EDM: front mold roughness, copper male, male mold line clear angle, rear mold bone position, pillow position;

Drilling, pinhole, thimble;

Line position, line position compression pole;

Slanting top;

Compound thimble, matching thimble;

Other: ① kinks, mold pit, garbage nails (limit nails); ② fly mold; ③ water spout, support head, spring, water transport;

Save mold, polishing, front mold, back mold bone position;

Fine water structure, tie rod screw pull hook, spring;

Important parts heat treatment, quenching, nitriding the surface of the row of bits;

Repair mold engraving.

What are the software used for mold-making processing?

Mold-making processing software commonly used in UGNX, Pro/NC, CATIA, MasterCAM, SurfCAM, TopSolid CAM, SPACE-E, CAMWORKS, WorkNC, TEBIS, HyperMILL, Powermill, GibbsCAM, FEATURECAM, and so on.

What are the basic characteristics of mold-making processing?

The basic characteristics of mold-making processing are the following 7 points.

(1) High machining accuracy requirements A pair of molds is generally composed of concave mold, convex mold, and mold frame, some may also be more than one piece of collocation module. So the combination of the upper and lower mold, the combination of inserts and cavities, and the combination between the modules requires a high degree of machining accuracy. Precision mold dimensional accuracy is often up to μm level.

(2) The complex shape of some products such as automobile covers, aircraft parts, toys, and household appliances, the shape of the surface is a combination of surfaces, so the mold cavity surface is very complex. Some surfaces must be processed by mathematical calculations.

(3) small batch The production of mold is not a large batch production, in many cases, often only a production.

(4) process more mold machining should always be used for milling, boring, drilling, reaming and tapping threads, and other processes.

(5) Repeatability of production The use of mold has a life. When the use of a mold exceeds its life expectancy, it is necessary to replace the new mold, so the production of molds is often repetitive.

(6) Imitation processing Mold production is sometimes neither drawings, nor data, and according to the physical imitation processing. This requires high imitation precision and no deformation.

(7) Mold material is excellent, and high hardness The main material of the mold is mostly made of high-quality alloy steel, especially the high life of the mold, often using Crl2, CrWMn, and other Leichhardt body steel manufacturing. This type of steel from the blank forging, and processing to heat treatment have strict requirements. Therefore, the preparation of processing technology can not be ignored, heat treatment deformation is also a serious problem to be treated in processing.

According to the above characteristics, in selecting machine tools, the processing requirements must be met as far as possible. Such as the function of the CNC system should be strong, high precision machine tools, rigidity should be good, thermal stability should be good, the function of profiling, and so on.

Molding processing flow

Processing flow arrangement.

- Bottom surface processing, processing volume guarantee;

- casting blank datum correction, 2D, 3D type surface allowance check;

- 2D, 3D type surface rough machining, non-installation of non-working plane machining (including the safety platform surface, buffer mounting surface, pressure plate plane, and side reference surface);

- Before semi-finishing machining, the side datum plane is corrected to ensure accuracy;

- semi-finishing 2D, and 3D type surfaces, finishing all kinds of installation work surfaces (including limit block mounting surface and contact surface, block mounting surface and backside, punch mounting surface, waste cutter mounting surface and backside, spring mounting surface and contact surface, all kinds of travel restriction work surface, inclined wedge mounting surface and backside), semi-finishing all kinds of guiding surfaces, guide holes, leaving a margin of finish machining process reference holes and height datum, and Record data;

- Inspection and review of machining accuracy;

- Clamping set work process;

- Before finishing, process datum hole datum plane correction, set block allowance check;

- Finishing profile 2D, 3D, side punching profile and holes, finishing process datum holes and height reference, finishing guide surface and guide holes;

- Inspection and review of machining accuracy.

Notes on mold-making processing

- Process preparation concise, detailed expression, processing content as much as possible numerical expression;

- Processing key difficulties, technology should be particularly emphasized;

- Need a combination of processing, process expression is clear;

- When the block needs to be processed separately, the process requirements of the precision of processing should be noted;

- Combined processing, need to be individually processed block parts, combined processing technology to install a separate processing of the benchmark requirements;

- Mold processing in the spring is the most easily damaged, so choose a long fatigue life for the mold spring. For example, the mold spring provided by DGMF.

Besides the What is Mold-Making article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?