What is cold stamping?

Cold stamping, also known as press working, is a manufacturing operation in which thermoplastics in sheet form are cold-formed using methods similar to those used in metalworking.

What is a cold stamping mold?

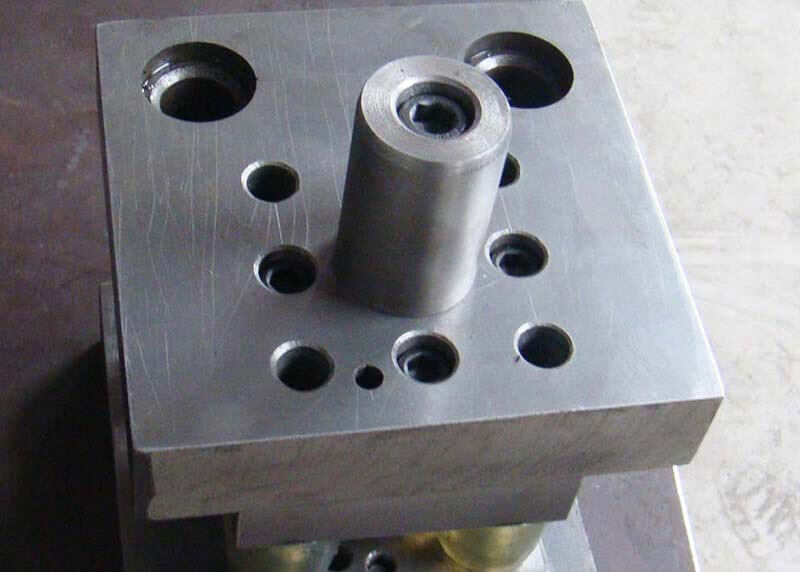

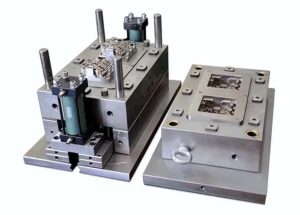

In the cold stamping process, special process equipment to process the material (metal or non-metal) into parts (or semi-finished products) is called cold stamping mold, commonly known as cold punching mold.

Cold stamping is a special tool installed on the press. It applies deformation force to the sheet material placed inside at room temperature to make it deformed to obtain a certain shape, size, and performance of the product parts.

What is the cold stamping process?

Cold stamping is a pressure processing method that uses a press to produce plastic deformation or separation of the material by applying pressure to the material at room temperature through a die to obtain the required shape and size of the part.

The workpiece processed by the stamping method is called a stamping part or pressed part.

What is the feature of cold stamping mold?

Cold stamping die is an essential process equipment in realizing cold stamping processing, and it has the same relationship with the stamping parts. Without a cold stamping mold that meets the requirements, qualified cold stamping parts cannot be produced, and without advanced cold stamping die, an advanced cold stamping forming process cannot be realized.

What is the advantage and disadvantage of cold stamping mold?

Compared with other processing methods, the cold stamping process has the following advantage and disadvantages:

(1) Compared with other processing methods, stamping can produce parts with complex shapes that are difficult or impossible to be processed by other processing methods.

For example, small-size and high-quality instrumentation parts, automobile coverings, longitudinal beams, etc.

(2) The products have good shape and dimensional accuracy, interchangeability, surface quality, and stability.

The dimensional accuracy can generally reach IT10-14 grade, and the highest fine blanking can reach IT6.

(3) High material utilization rate

Cold stamping is less or no chip processing, less material depletion, and the material utilization rate is generally up to 70%~85%.

(4) Simple operation

The production process is easy to achieve through mechanization and automation, and the production efficiency is high, especially suitable for mass production.

(5) The disadvantages of the stamping process are the long cycle time and the high cost of mold manufacturing. The noise during stamping is very high, so it is unsuitable for single-piece or small-batch production.

What is the development history of cold stamping mold?

Since the 1920s, metal products, toys, and small hardware industries have used simple machinery and equipment such as punching machines, presses, and corresponding molds to process product blanks or certain parts.

After the 50s, due to the addition of grinding machines, milling machines, sawing machines, and other equipment, and with hardness tester, outside diameter and inside diameter tester, and block gauge, the precision of cold stamping die can be improved.

With the production of products using a large number of stamping machine tools, 1960 ~ 1970, cold punching die has been developed from the original single punching drop, single punching die for the drop, and punching composite die.

Also, the mold design structure in various forms and precision improved due to the emergence of standard parts of cold punching die frames. At the same time, with the progress of heat treatment technology and detection means of perfection, cold punching die life increased by 5 to 7 times.

During this period, due to the molding grinding, electric pulse and wire cutting machine tools used one after another, and the use of cemented carbide for mold materials, the cold punching die production process has a new development.

The service life of carbide cold punching dies jumped from 35,000 times to more than 1.5 million times. As the designers improve the mold-making process, many compound molds with automatic feeding, automatic sheeting, and receiving devices are introduced.

After the introduction of the die milling machine, the same shape of the die core can be turned out with plaster, wooden mold, or in kind, which provides convenience to making compound drawing die and ensures accuracy.

After the 70s, the bevel wire cutting machine processing cold punching die, its convex die (punch), and concave die can be quenched before cutting assembly, replacing the original cold punching die production: heat treatment – assembly – deformation correction of the tedious process.

Die finish also correspondingly improves a grade. The accuracy can reach 0.01 mm. Later, each professional mold factory and mold workshop group widely used wire-cutting machine processing to make cold punching dies.

What is the classification of cold stamping mold?

There are many forms of stamping dies, which can be generally classified according to the following main features.

Classification according to the nature of the process

(1) Punching die

A punching die is a die that separates materials along a closed or open contour line. Such as drop die, punching die, cutting die, cutting die, cutting edge die, cutting die, etc.

(2) Bending die

Make the slab blank or other blanks along the straight line (bending line) to produce bending deformation to obtain a certain angle and shape of the workpiece mold called bending die.

(3) Deep drawing die

The deep-drawing die is to make the sheet blank into open hollow parts or make hollow parts further to change the shape and size of the mold.

(4) Forming die

Forming die is the blank or semi-finished workpiece according to the shape of the convex and concave mold directly copy forming, and the material itself produces local plastic deformation of the mold. Such as expansion die, indentation dies, flaring die, undulation forming die, flanging die, shaping die, etc.

According to the cold stamping process, combination degree classification

(1) Single-process die

In one press stroke, only one stamping process is completed in the die, called a single process dies.

(2) Composite die

A die with only one workstation and completing two or more stamping processes at the same workstation in one press stroke is called a compound die.

(3) Progressive die (also called a continuous die)

A die that has two or more stations in the feeding direction of the blank and completes two or more stamping processes at different stations one after another in one stroke of the press is called a progressive die.

Classification according to the deformation characteristics of the cold stamping steel material

Main materials: hot rolled and cold rolled steel sheets and strips, cast iron.

60-70% of the world’s steel is the plate, most of which is stamped into finished products.

What is the applications of cold stamping mold?

The application of cold stamping processing is very wide

According to statistics, 60%~70% of the parts in automobile manufacturing, electromechanical, and instrumentation production are made by stamping; in electronic products, the number of stamping parts accounts for more than 85% of the total number of parts.

Development of cold stamping and molds

In recent years, the application of new technologies such as computer-aided design and auxiliary manufacturing technology (mold CAD/CAM), sheet metal forming simulation technology (stamping CAE), rapid forming (RPM), and various conventional casting and powder sintering processes combined with the development of rapid mold manufacturing technology, as well as the application of new processes such as precision blanking, hydraulic forming, and superplastic forming, make stamping technology has reached a new level.

Here we correct 30 Die Stamping Problems And Troubleshooting. Please click here to learn more.

Besides the What is a Cold Stamping Mold article, you may also be interested in the below articles.

Plastic Injection Molding vs. 3D Printing What’s the Difference?

Extrusion vs. Injection Molding, What Is The Difference?

Injection Molding vs. Thermoforming, What’s the Difference?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?