Analysis of the causes the injection molding flashes in injection molded products.

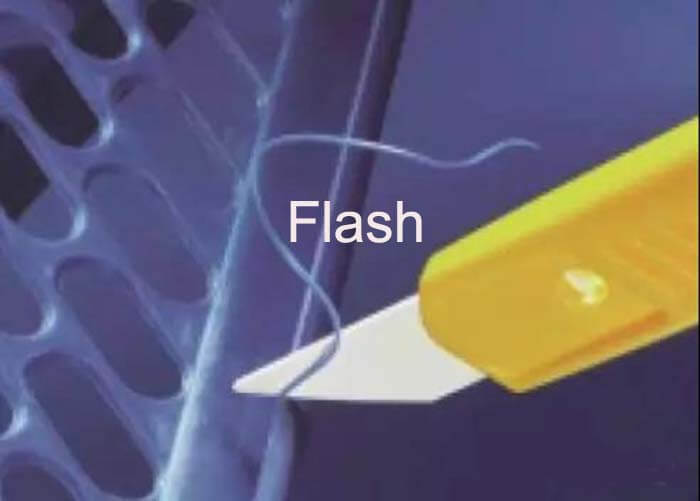

What is an injection molding flash defect?

Injection mold flash, or mold flashing, is excess plastic that forms on the surface of injection molded parts. This unwanted material is usually forced out of the injection mold cavity at the parting line but can also emerge from other locations.

Most of the injection molding flashes happen on the parting surface, i.e. between the moving mold and the static mold, the sliding part of the sliding block, the gap of the insert, the hole of the top bar, etc., where the melt flows in and forms a superfluous flying edge burr on the part.

Such an edge injection molding flash, when forming the role of leverage, will make the flying edge burr further increase, thus causing the mold local depression, the formation of a vicious circle when the injection molding flashes into an increase.

Therefore, if an injection molding flash is detected at the outset, the injection mold must be trimmed as soon as possible.

The injection molding flashes can occur for 6 reasons.

1. Insufficient clamping force causes injection molding flash defect

If the clamping force is small compared to the projected area of the molded part, a gap will appear between the moving and static molds due to the injection pressure, which will inevitably result in a cause injection molding flash defect.

This is particularly the case when the side gate is placed over a hole near the center of the part, as this type of molding gate requires a higher injection pressure and is, therefore, more prone to burrs.

Reducing the injection pressure or increasing the clamping force can eliminate this defect, and sometimes it is also very effective to use low-pressure molding with good flowing plastic depending on the situation.

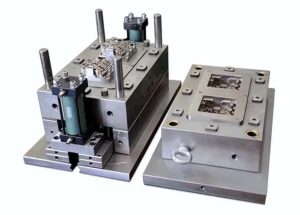

2. Poor local fit of the mold causes injection molding flash defect

First of all, we will discuss the problem of poorly fitted molds. Although the injection molds themselves are tightly fitted, when an injection molding machine with an elbow bar clamping mechanism is used, it is often due to poor parallelism of the mold or poor adjustment of the clamping device, resulting in phenomena such as uneven clamping on the left and right sides, i.e. only the left and right sides are locked, and the other side is not tightly fitted when In this case, the tie rods (two or four cuttings) must be adjusted so that they are balanced.

Secondly, there are also cases where the molds themselves are not well-matched, resulting in a poor fit. Especially when there is a forming hole in the center of the part, when the clamping force is not sufficient, due to the supporting role of this part, it is also easy to injection molding flashes.

The other is the sliding core because along the moving core is the action mechanism, often producing injection molding flashes, so the sliding core fit is very important.

This is especially true for left and right parting wafers, where the projected area on the sides is also subject to injection molding pressure, and if the design is not fully capable of withstanding this pressure, injection molding flashes often occur.

The gap in the insert and the hole in the ejector rod, not only produce a vicious circle of increasing causes injection molding flashes but also increases the ejection resistance.

3. Injection mold deflection causes injection molding flash defect

If the mold is not sufficiently original, it will be deflected by the injection pressure, and if there is a hole near the center, injection molding flash will be produced around the hole; also when the center hole is used to open the side gate, injection molding flashes will be produced around the hole and the sprue.

Burrs from this cause are caused by poorly made molds and are therefore more difficult to repair. The injection molding flash can be reduced by reinforcing the injection mold.

4. Excessive plastic flow causes injection molding flash defect

The mere fact that the plastic is too fluid is not, in theory, a cause of burrs. However, when the plastic is too fluid, it can get into even the smallest of gaps, so injection molding flashes are very likely to occur.

To eliminate this injection molding flash defect, the melt temperature or injection molding pressure can be lowered, as can the injection mold temperature or injection molding speed.

5. Over-injection of melt causes injection molding flash defect

This is also not a direct cause of injection molding flashes. It is wrong to inject too much melt to prevent shrinkage. Increase the injection time or holding time for molding (cf. shrinkage).

6. Foreign objects on the mold surface

The presence of foreign matter on the molding surface is bound to produce injection molding flashes.

To solve this problem, the surface of the mold should be cleaned so that the surface of the mold can be tightly fitted.

Besides this article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept