The article talks about the top ten fixture clamps commonly used in the machining industry.

Why fixture clamp is so important?

Fixture clamps offer a wide assortment of style clamps that are adaptable to different industrial applications and systems.

Machining applications require the right tools and equipment to get the best results. If you lack the right equipment, you will find yourself working with processes that are much more difficult than they need to be. You will also face increasing customer dissatisfaction, which can cost you money.

Fixture clamps are just one important component that can be used in many industries and applications, from automotive manufacturing to factories. This guide covers some of the basics of these clamps, so you can make an informed decision when looking for accessories.

What is the use of fixture clamps?

Fixture clamps are used to hold different parts in place, which is an important part of the machining process. In addition to maintaining sturdy segments, fixture clamps must promote proper movement and flexibility when working with components. Custom solutions may also be necessary for specific uses that go beyond the process specifications.

The top 10 types of Fixture Clamps

There are many fixture clamp designs to choose from, which can make the selection process challenging. These are the top ten fixture clamps and how they work.

Fixture Clamp Types Tenth: Indexing Head/Dividing Head

The indexing dividing head is mainly used for machining, the workpiece mounted on the spindle is divided into any equal parts or rotated any number of degrees, high-precision indexing head/dividing head is also used for the measurement of the angle.

The indexing head spindle is used to clamp the workpiece. By shaking the handle, the spindle rotates according to a certain transmission ratio, which is also called indexing fixed number. Generally, there are 40 and 90, that is, the spindle rotates at 9° and 4° respectively when the handle rotates one turn.

Simple indexing is the use of the different numbers of holes on the indexing disc and positioning pins to achieve the required number of equal parts of the workpiece through calculation, which is the most common method of indexing the head in the machinery industry.

Angular indexing is another form of simple indexing, which is performed according to the angle of the workpiece to be indexed or the angle of rotation required. If the indexing head/dividing head has a fixed indexing number of 40, the indexing handle turns 40 turns and the spindle turns 360°, the handle turns one turn and the spindle turns only 9°.

Operation method: According to the indexing method of simple indexing above, the indexing handle is on the 54-hole disk and rotates 30 hole pitches to get the required rotation of 5°.

When the indexing accuracy requirement is low, turn the indexing handle, and you can read the indexing directly according to the vernier ring scale on the body.

Fixture Clamp Types Ninth: Pneumatic Clamping Air Cylinder

Pneumatic Clamping Air Cylinder Detailed introduction

- Can fix the sensor.

- The high degree of freedom of the fixed way.

- The whole shaft adopts a double clamping method.

- Synchronization of clamping jaws by rack and pinion. 5.

- 1 unit can be used for a variety of workpiece diameters.

- Double piston structure to achieve compact and large clamping force.

The essence of automatic Pneumatic cylinder clamp. Among many clamps, the laborer should like the pneumatic clamps the most.

Pneumatic Clamping Air Cylinder Features

- The design of the double piston structure realizes compact and large clamping force.

- Easy maintenance by using composite bearing.

- The internal Fourier wheel is equipped with the bacterium bar to achieve synchronization with the clamping jaws.

- Multiple directions can be installed and positioned.

- All series with magnets can be added with time.

- Long jaw strokes can clamp different sizes of workpieces at the same time.

Fixture Clamp Types Eighth: Spring Collet Chuck

How to solve the clamping problem with fewer tool grips for tools with many specifications? Here you can find the answer.

Spring collet in the field of CNC equipment is a fixture clamp that cannot be missed.

Centering machine tungsten steel collet chucks, guide bushings, white steel collets, spindle taper bushings, adapters, barren jaws, chuck jaws, spindle springs, pneumatic chucks, four or six square collet chucks, non-standard collets customization, etc.

Fixture Clamp Types Seventh: Magnetic Chuck

How to make it easier to put the parts without clamping position on the worktable for you to process? See how he did it?

Magnetic chuck is common instrumentation in industry, this machine and equipment mainly use the principle of magnetism, in some large processing plants are also more common, can improve efficiency.

Magnetic chucks are generally used in the mold manufacturing industry and can be used to process some parts with magnetic. Magnetic chucks are used in the strength system as a tool that can be magnetically conductive.

Fixture Clamp Types Sixth: ToolholderSpindle Interfaces

The Toolholder/Spindle Interfaces for CNC Machine Tools is the crystallization of top human intelligence and cutting-edge technology.

A tool is a tool used for cutting and processing in machinery manufacturing, also known as cutting tools. The vast majority of tools are for machine use, but there are also hand-operated ones.

Since the Toolholder/Spindle Interfaces for CNC machine tools used in mechanical engineering are used to cut metal materials, the term tool is generally understood as metal cutting tools.

Fixture Clamp Types Fifth: Machine Vise and Mace

The workpiece that cannot be pressed by the press plate should be considered to be clamped by machine vise/mace.

Machine vise is the main fixture clamp for planers, milling machines, drilling machines, grinding machines, and inserting machines, widely used in milling machines, drilling machines, etc. for a variety of flat, groove, angle, and other processing.

The machine vise adopts a multi-functional modular design, and the structure is composed of a vise body, base, guide nut, screw, jaw body, etc.

The machine vise is mainly a general-purpose fixture clamp used to clamp the workpiece. Install it on the workbench you need to clamp and stabilize and clamp the workpiece to be processed for secondary operation processing of the workpiece.

A machine vise is a tool that uses a screw or other mechanism to make the two jaws move relative to each other and clamp the workpiece. The movable jaws of the machine vise also have pneumatic, hydraulic, or eccentric cam to drive the fast clamping.

Machine vise for pliers, factory workshops, and other necessary a tool, but also repair, shear, to be processed when the need for a fixture clamp tool.

Machine vise installation and use can move the base or rotate the vise body so that the workpiece rotates to a more suitable working position you need. For the clamp workshop necessary tools.

Fixture Clamp Types Fourth: Pneumatic Chuck

The high precision pneumatic chuck fixtures for CNC machining for higher productivity and mass production.

Pneumatic power chuck can guarantee /-0.002mm repeatable positioning accuracy. Electrode without it can not; four-axis machining without it can not; five-axis machining without it can not.

Features of pneumatic chucks

- Accuracy: Repeat accuracy of the positioning piece is guaranteed within 0.002mm, which greatly improves the accuracy of the mold, and the standard reference system is easy to use and quick to set up, which greatly improves the processing efficiency.

- Inspection: Each electrode is inspected outside the machine, which saves time and ensures accuracy, without the need to hit the table on the machine to correct, greatly improving the utilization of the machine.

- Standard interface: all machine tables are the same, unifying the connection ports of various machines, making the conversion between processes smoother and more accurate.

- Speed: switching from one process to another, only some simple steps are needed to quickly reset the machine to achieve a rapid change of the workpiece, no need to hit the table correction, really increases the time of machine production!

Fixture Clamp Types Third: CNC T-slot table

A CNC T-slot table, also known as a T-slot plate, is a kind of industrial gauge, mainly used to fix the workpiece, and is used by the clamp workers to debug the equipment, assembly equipment, maintenance equipment, and the basic work platform.

Fixture Clamp Types Second: Lathe Chuck

The lathe chuck is a mechanical device fixture clamp used to clamp the workpiece on the machine tool. The use of evenly distributed lathe chuck body of the radial movement of the movable jaws, the workpiece clamping, and positioning of machine tool accessories.

A lathe chuck is generally composed of a chuck body, movable jaws, and a jaw drive mechanism 3 parts. The minimum diameter of the lathe chuck body is 65 mm, up to 1500 mm, with a central hole to pass the workpiece or bar; the back has a cylindrical or short conical structure, directly or through the flange, and the machine tool spindle end connected.

The lathe chucks are usually mounted for use on lathes, cylindrical grinders, and internal grinders, and can also be used on milling and drilling machines in conjunction with various indexing devices.

Centuries-old lathe chuck fixture clamps are still busy in machine shops. Its classicism speaks for itself. There are more chucks in the shop than lathes. If there is no chuck the lathe can not afford to operate.

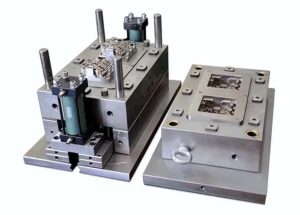

Fixture Clamp Types No. 1: Mold Clamp Assembly

Other fixture clamps do not have the mold clamp, T bolt, and nut assembly you can hardly install to the machine (for milling machines, and machining centers). If you don’t believe me, go ahead and try it.

Here are the DGMF’s mold clamp assemblies:

Quick-change mold clamp with T bolt and flange nut assembly

Quick-change mold clamp with clamping stud bolt with spanner and Hex nut assembly

Closed-end mold clamp with T bolt and flange nut assembly

Step blocks and strap clamps

Universal mold clamp with T bolt and flange nut assembly

Easy mold clamp with T bolt and nut assembly

Hold down clamps use 2pcs as a set

Forged mold clamp with clamping stud, Hex nut, and mold clamp washer assembly

If you not find the suitable fixture clamps, please do not hesitate to contact DGMF Mold Clamps Co., Ltd, we may can help you with.

Besides the Top 10 Fixture Clamp Types In The Machining article, you may also be interested in the below articles?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept