Description

What is a Tool Holder for Milling Machine?

A tool holder is a device that safely provides a critical interface between the cutting tool and the spindle of the CNC machine.

The cutting tool is mounted into the holder and is tightened so it does not move or vibrate during machining; providing the stability you need to ensure precision cuts every time.

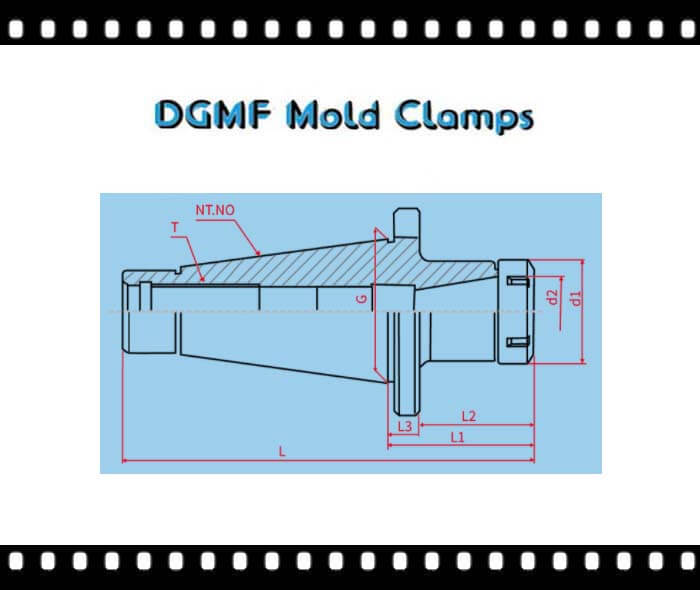

The tool holder boring head shank tool shank is a boring tool shank for a high-accuracy boring head for milling machines. The shank is the cylindrical (non-fluted) part of the tool which is used to hold and locate it in the tool holder.

A tool holder is a tool that connects a machine spindle to a tool and other accessory tools. The current main standards are BT, NT, R8, NBT, and several other spindle models.

What are the different types of tool holders for CNC milling machines?

Here are the basic types of CNC milling tool holders available for your machine: Collet chuck. Shrink fit holder. Tap holder.

What is the purpose of a tool holder?

The tool holder is a general term for the adapters used to mount the cutting tools in the machine-tool equipment that performs these operations.

Tool holders influence the machining accuracy of machine tools and even product quality, so they demand high precision for which not even microscopic error is permitted.

What are the advantages of a tool holder?

The advantages of using an advanced tool holder that holds rigidity, accuracy, power, and balance are extended cutting tool life, extended spindle life, better surface finish, and accuracy of parts.

Tool Holder Types’ Features and Tool Shank Specifications

High-Accuracy BT Tool Holder Type Boring Head Shank for Milling Machine Features:

Material: 20CRMNTI

Hardness: HRC56°-58°

True roundness: <0.8u

Carburizing depth: >0.8mm

Accuracy level: G2.5 grade

Standard speed: below 12,000rpm

Dynamic balancing speed: below 30,000rpm

BT Tool Shank Specifications:

| BT Toolholder Specifications | d1 | L1 | L2 | L |

| BT30-ER11A-70 | 19 | 70 | 48 | 118.4 |

| BT30-ER11A-100 | 19 | 100 | 78 | 148.4 |

| BT30-ER16A-70 | 28 | 70 | 48 | 148.4 |

| BT30-ER16A-100 | 28 | 100 | 78 | 148.4 |

| BT30-ER20A-70 | 34 | 70 | 48 | 148.4 |

| BT30-ER20A-100 | 34 | 100 | 78 | 148.4 |

| BT30-ER25-70 | 42 | 70 | 48 | 148.4 |

| BT30-ER25-100 | 42 | 100 | 78 | 148.4 |

| BT30-ER32-70 | 50 | 70 | 48 | 148.4 |

| BT40-ER11A-70 | 19 | 70 | 43 | 135.4 |

| BT40-ER11A-100 | 19 | 100 | 73 | 165.4 |

| BT40-ER16A-70 | 28 | 70 | 43 | 135.4 |

| BT40-ER16A-100 | 28 | 100 | 73 | 165.4 |

| BT40-ER20A-70 | 34 | 70 | 43 | 135.4 |

| BT40-ER20A-100 | 34 | 100 | 73 | 165.4 |

| BT40-ER25-70 | 42 | 70 | 43 | 135.4 |

| BT40-ER25-100 | 42 | 100 | 73 | 165.4 |

| BT40-ER32-70 | 50 | 70 | 43 | 135.4 |

| BT40-ER32-100 | 50 | 100 | 73 | 165.4 |

| BT40-ER40-80 | 50 | 80 | 43 | 145.4 |

| BT50-ER25-100 | 42 | 100 | 73 | 201.8 |

| BT50-ER32-100 | 50 | 100 | 73 | 201.8 |

| BT50-ER40-100 | 63 | 100 | 73 | 201.8 |

High-Accuracy NBT Tool Holder Type Boring Head Shank for Milling Machine Features:

Name: NBT keyless slotted ER tool holder

Material: 20CRMNTI

Hardness: HRC56°-58°

Rotation speed:30,000rpm

Body accuracy:≤0.03mm

Carburization depth:>0.8mm

Accessories: spanner, spigot free

Clamping accuracy: ≤0.008mm

Applicable spindle: NBT30/NBT40 keyless spindle

NBT Tool Shank Specifications:

| NBT Tool Holder Specifications | L | L1 | D1 | Nut | Collet | Clamping range |

| NBT30-ER16-70L | 70 | 48 | 28 | ER16A | ER16 | 1-10 |

| NBT30-ER16-100L | 100 | 78 | 28 | ER16A | ER16 | 1-10 |

| NBT30-ER20-70L | 70 | 48 | 34 | ER20A | ER20 | 1-13 |

| NBT30-ER20-100L | 100 | 78 | 34 | ER20A | ER20 | 1-13 |

| NBT30-ER25-70L | 70 | 48 | 42 | ER25UM | ER25UM | 1-16 |

| NBT30-ER25-100L | 100 | 78 | 42 | ER25UM | ER25UM | 1-16 |

| NBT30-ER32-70L | 70 | 48 | 50 | ER32UM | ER32UM | 2-20 |

| NBT30-ER32-100L | 100 | 78 | 50 | ER32UM | ER32UM | 2-20 |

High-Accuracy NT Tool Holder Type Boring Head Shank for Milling Machine Features:

Name: NT tool holder

Material: 40CR

Hardness: HRC46°-50°

NT Tool Shank Specifications:

| NT Tool Holder Specifications | L | L1 | D1 |

| NT30-ER16-45L | 113.4 | 45 | 28 |

| NT30-ER20-45L | 113.4 | 45 | 34 |

| NT30-ER25-55L | 123.4 | 55 | 42 |

| NT30-ER32-60L | 128.4 | 60 | 50 |

| NT30-ER40-70L | 138.4 | 70 | 63 |

| NT4O-ER16-45L | 138.4 | 45 | 28 |

| NT40-ER20-45L | 138.4 | 45 | 34 |

| NT40-ER25-55L | 148.4 | 55 | 42 |

| NT40-ER32-60L | 153.4 | 60 | 50 |

| NT40-ER40-70L | 163.4 | 70 | 63 |

| NT50-ER16-100L | 226.8 | 100 | 28 |

| NT50-ER20-100L | 226.8 | 100 | 34 |

| NT50-ER25-100L | 226.8 | 100 | 42 |

| NT50-ER32-75L | 201.8 | 75 | 50 |

| NT50-ER32-100L | 226.8 | 100 | 50 |

| NT50-ER40-80L | 226.8 | 80 | 63 |

| NT50-ER40-100L | 226.8 | 100 | 63 |

| NT50-ER50-80L | 226.8 | 80 | 78 |

| NT50-ER50-100L | 226.8 | 100 | 78 |

High-Accuracy R8 Tool Holder Type Boring Head Shank for Milling Machine Features:

Vibration and bending resistant

Made of high-quality materials

Not easily deformed

Ensures accuracy

Clearly threaded

Clear threads on the shank

The nut can be turned directly

High rigidity

R8 Tool Shank Specifications:

| R8 Tool Holder Specifications | Nut | ID | Collet | Clamping range |

| R8-ER16 | (M12)/(M5/8) | A:28/B:23 | ER16 | 1-10 |

| R8-ER25 | (M12)/(M5/8) | 42 | ER25 | 1-16 |

| R8-ER32 | (M12)/(M5/8) | 50 | ER32 | 1-20 |

| R8-ER40 | (M12)/(M5/8) | 63 | ER40 | 3-26 |

C-type Tool Shank Boring Head Straight Shank Features:

Superior steel for durability

Selected from high-quality 40CrMnTi with carburizing and quenching process

High surface hardness, with high fatigue resistance and high wear resistance

High concentricity of internal and external grinding

High concentricity for good machining results and improved machining efficiency

Extended tool life

C12 for 12mm shank diameter

FMB22 for shank diameters 50-63mm

FMB27 for cutter diameters of 80mm

FMB32 for cutter diameters of 100mm

C-type Tool Shank Boring Head Straight Shank Specifications:

| Boring Head Straight Shank Specifications | C | D | L |

| C20-FMB22 | 20 | 22 | 50/63 |

| C20-FMB27 | 20 | 27 | 80 |

| C20-FMB32 | 20 | 32 | 100/125 |

| C20-FMB22 | 25 | 22 | 50/63 |

| C20-FMB27 | 25 | 27 | 80 |

There are many different machine tool holder types and tool shank specifications available at DGMF Mold Clamps Co., Ltd, if you cannot find the one you want on this page, or you want more machine tool holder information such as machine tool holder pricing, machine tool holder inventory.

Please contact our sales, thank you.

DGMF Mold Clamps Co., Ltd is the mold clamps Manufacturer in China, also providing injection mold components, die press components, machine tools, and fasteners for your best choice. Please do not hesitate to contact us, thank you.

What are the Principles of tool holder balancing?

The dynamic balancing principle for rotating tools is similar to that of rotating parts in general.

The balance is achieved by removing the eccentric weight or by adjusting the counterweight, etc. After the dynamic balancing setting, the tool is machined smoothly, with more stable accuracy, less vibration, and higher speed.

High-speed machining of tools up to 30,000 rpm is possible.

Machine Tool Holder types for F1 boring heads tool shanks

The boring tool shanks for high-accuracy F1 boring heads for milling machine work with many tool holder types such as R8 F1, NT30/40/50, BT30/40/50, MT3/4/5, C20/25, etc.

Boring Head Sets

High-accuracy F1 Boring Head for Milling Machine works with the boring bar shank R8 F1-M12, R8 F1-7/16″, NT30, NT40, NT50, BT30, BT40, BT50, MT3, MT4, MT5, C20, C25, etc.

Each boring headset has different components, please contact the DGMF team for more details.

R8 boring head set

NT30 boring head set

NT40 boring head set

NT50 boring head set

BT30 boring head set

BT40 boring head set

BT50 boring head set

MT3 boring head set

MT4 boring head set

MT5 boring head set

C20 boring head set

C25 boring head set