Die Press Components

-

DGMF Straight Ejector Pins

Read more -

DGMF Shoulder Ejector Pins

Read more -

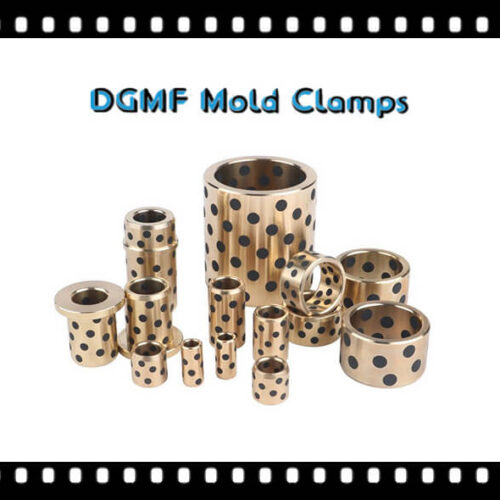

DGMF Self-lubricating Guide Bushings For Injection Molding

Read more -

DGMF Self-lubricating Bronze Wear Plates

Read more -

DGMF Precision Shoulder Punches for Stamping Die

Read more -

DGMF Precision Guide Bushings for Mold

Read more -

DGMF Movable Stoppers for Ball Guide Post Sets

Read more -

DGMF Mold Springs Die Springs

Read more -

DGMF High-precision Angle Pins

Read more -

DGMF Guide Pins For Injection Molding

Read more -

DGMF Guide Pins And Bushings

Read more -

DGMF Fixed Stoppers for Ball Cage Guides

Read more -

DGMF Ejector Sleeve Pins

Read more -

DGMF Ejector Blades

Read more -

DGMF Core Pins for Molding

Read more -

DGMF Ball Cages For Die Sets

Read more -

DGMF Ball Bearing Guide Post Sets For Die Guides

Read more

Stamping Die Press Components Supplier

DGMF Mold Clamps Co., Ltd is the stamping die press components supplier and mould clamps manufacturer in China.

What is stamping die?

Stamping dies are the main process equipment for stamping processing, and the stamping dies components are completed by the relative movement of the upper and lower dies.

During the processing, due to the continuous separation and closing of the upper and lower molds, if the operator’s fingers continuously enter or stay in the mold-closed area, it will pose a serious threat to his personal safety.

Main die press components and safety requirements

1. Working components

The convex and concave mold is the working part that directly makes the blank shape, therefore, it is the key part of the mold. The convex and concave mold is not only precise but also complex, it should meet the following requirements:

(1) It should have sufficient strength and cannot be broken or damaged during the stamping process;

(2) Appropriate requirements should be placed on its materials and heat treatment to prevent brittleness due to high hardness.

2. Positioning components

Positioning components are parts that determine the installation position of the blank. There are positioning dowel pins, stop pins, guide pins, guide bushings, fixed distance side knives, side presses, etc.

When designing positioning parts, you should consider the convenience of operation, there should be no positioning, and the position should be easy to observe. It is best to use forward positioning, outer profile positioning, and guiding pin positioning.

3. Pressing, unloading, and discharging components

The blanking parts include a blanking ring, blanking board, etc. The blank holder can exert pressure on the drawn blank, thereby preventing the blank from arching and forming wrinkles under the action of tangential pressure.

The function of the holding plate is to prevent the blank from moving and bouncing.

The function of the ejector and unloading plate is to facilitate the ejection of parts and the cleaning of waste. They are supported by springs, rubbers, and air cushion pushrods on the equipment, and can move up and down.

The ejector pins should have sufficient ejection force and the movement should be limited. The unloading board should minimize the closed area or mill an empty slot in the operating position.

The exposed unloading plate shall be surrounded by protective plates to prevent people from reaching out with fingers or foreign objects from entering, and the edges and corners of the exposed surface shall be blunt.

4. Guide components

Guide bushings and guide pins are the most widely used guide components. Its function is to ensure that the convex and concave dies have a precise fit clearance during the stamping work.

Therefore, the gap between the guide bushing and the guide pin should be smaller than the blanking gap. The guide bushing is set on the lower mold base, and the upper-end surface of the guide pin is at least 5 to 10 mm above the top surface of the upper template at the bottom dead center of the stroke.

The guide bushing should be arranged far away from the module and the pressing plate so that the operator’s arm does not need to cross the guide bushing to feed and take materials.

5. Support pillar and mold clamp

It includes upper and lower templates, mold handles, fixed plates for convex and concave molds, backing plates, stoppers, mold clamp, etc. The upper and lower templates are the basic components of the die; various other components are installed and fixed on it.

The plane size of the template, especially the front and rear direction, should be compatible with the workpiece, too large or too small is not conducive to operation.

Some molds (blanking, punching molds) need to set up a backing plate under the mold base for the convenience of parting. At this time, it is better to connect the backing plate and the template with screws, and the thickness of the two backing plates should be absolutely equal.

The spacing of the backing plates shall be subject to the parts that can be delivered and should not be too large to prevent the template from breaking.

6. Fasteners

It includes screws, nuts, springs, pins, washers, etc.

Standard parts are generally used. There are a lot of standard components of stamping dies, and the design and selection should ensure the needs of tightening and elastic ejection, avoiding the fasteners from being exposed on the surface operation position, and preventing hand injury and hindering operation.

Safety points of mold design

The structure should try to ensure the convenience of feeding, ordering, discharging, and cleaning up waste. For the processing of small parts, it is strictly forbidden for the operator’s fingers, wrist, or other parts of the body to extend into the mold area;

For the processing of large parts, if the operator must manually enter the mold, he should reduce the scope of the mold as much as possible, shorten the time that a certain part of the body stays in the mold as much as possible, and clarify the danger zone of the mold and provide the necessary equipment. Protective measures and devices.

The various parts of the mold should have sufficient strength and rigidity to prevent damage and deformation during use. The fastening parts should have anti-loose measures to avoid accidental injury to the operator.

It is not allowed to produce waste or workpiece missiles during the processing, which will affect the attention of the operator or even hurt the operator. In addition, it is necessary to avoid cuts from the burrs of the blanking parts.

The operator is not allowed to have too large a motion range during the punching operation, and avoid the posture that makes the body lose stability;

Excessive and over-accurate actions are not allowed during operation. Try to avoid strong noise and vibration during stamping.

The mold design should indicate the mold weight on the general drawing for easy installation and safety. Lifting and handling measures should be adopted for the processing of parts over 20 kg to reduce labor intensity.

When assembling and disassembling mold parts, it should be convenient and safe to avoid pinching or cutting hands. The mold should be easy to disassemble and store.

In short, even minor problems in the mold will affect safety. Only by analyzing the specific problems in each job can the safety precautions in the mold be put forward.

DGMF Mold Clamps Co., Ltd manufactures the mold clamps, supplies the injection mold components, such as Clamps, Toggle Clamps, C Clamps, Pins, Bushings, Positioning Components, Lock Mold Components, Reset Extrusion, Cavity, and Core Components, Coolings, Die Press Components, Punch And Die, Guide Components, Self-lubricating Components, Springs, Machine Tools, gate valves, Machine Mounts, Vises, Fasteners, Lifting, Bolts, Nuts, Washers, etc.

Contact the DGMF Mold Clamps teams for more details about the stamping die press components such as die press components specifications, pricing, inventory, etc.

Showing 1–16 of 17 results

-

DGMF Ball Bearing Guide Post Sets For Die Guides

Read more -

DGMF Ball Cages For Die Sets

Read more -

DGMF Core Pins for Molding

Read more -

DGMF Ejector Blades

Read more -

DGMF Ejector Sleeve Pins

Read more -

DGMF Fixed Stoppers for Ball Cage Guides

Read more -

DGMF Guide Pins And Bushings

Read more -

DGMF Guide Pins For Injection Molding

Read more -

DGMF High-precision Angle Pins

Read more -

DGMF Mold Springs Die Springs

Read more -

DGMF Movable Stoppers for Ball Guide Post Sets

Read more -

DGMF Precision Guide Bushings for Mold

Read more -

DGMF Precision Shoulder Punches for Stamping Die

Read more -

DGMF Self-lubricating Bronze Wear Plates

Read more -

DGMF Self-lubricating Guide Bushings For Injection Molding

Read more -

DGMF Shoulder Ejector Pins

Read more