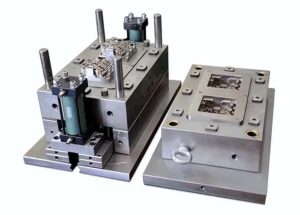

This article mainly talks about the analysis and solution of the problem of the insufficient mold opening force of the injection molding machine.

What should I do if the mold opening force of the injection molding machine is insufficient?

What is mold opening force insufficient?

1. The area of the mold opening hydraulic ring is too small

Mold opening force = mold opening oil pressure ring area × mold opening oil pressure

Under the condition of determining the maximum pressure, if you want to increase the mold opening force, you can only increase the mold opening oil pressure ring area, and you can increase the mold opening oil pressure ring area by increasing the cylinder diameter or reducing the piston rod diameter.

2. The gap between the mold opening and the oil is too small

In the mold opening section, because the clearance between the hydraulic buffer sleeve and the inner hole of the front cover of the cylinder is too small, the pressure oil is slow or even difficult to enter the cylinder opening cavity, so the maximum mold opening force cannot be provided.

Increase the matching gap between the hydraulic buffer sleeve and the inner hole of the front cover of the cylinder, so that the pressure oil can quickly enter the cylinder opening cavity and form a mold opening force with a certain momentum, which may cause a certain impact when the mold is opened.

3. The θ angle exceeds 90° after high-pressure clamping, resulting in the reverse hinge

The design of the hinge parameters and the stroke and installation position of the clamping cylinder determine the end position of the small hinge during the final high-pressure clamping and form an θ angle.

The designed θ angle must ensure that the machine is installed within the cumulative tolerance range of each part processing the θ angle must be less than 90°. Once the θ angle exceeds 90°, the small hinge will appear reverse hinge.

At the moment of mold opening, the hook hinge and the long hinge are moved in a straight line to generate greater clamping force. The mold opening force is too small to overcome the deformation force caused by increasing the clamping force, so the mold opening cannot be completed instantly.

4. Excessive mold clamping pressure and flow lead to overload of clamping force, too large deformation force of machine hinge, mold opening force cannot overcome excessive deformation force

When the machine hinge of the machine reaming machine is designed, the magnification ratio of the machine reaming when it produces the predetermined clamping force to be achieved has also been determined.

Based on this, the required thrust of the mold-clamping cylinder can be designed to determine the diameter of the mold-clamping cylinder. This cylinder must also ensure sufficient mold opening force. For sufficient mold opening force, it is hoped that the larger the cylinder diameter, the better.

If the cylinder diameter is too large, the cylinder thrust during mold clamping is too large and the clamping force is overloaded (when the mold adjustment is not good).

In this case, it is usually possible to prevent the clamping force from overloading by limiting the high-pressure clamping pressure and flow rate. Be patient when adjusting the mold, and use the lower clamping pressure to adjust the clamping force as much as possible.

5. The mold opening pressure is low and the flow rate is small, resulting in a small mold opening impulse

Due to the low mold opening pressure and low flow rate, the mold opening impulse is small, which cannot overcome the deformation force of the machine hinge.

In particular, the first stage mold opening flow provided by the servo control system is small, and the mold opening impulse is smaller, making it more difficult to open the mold. This problem can increase the mold opening impulse by modifying the controller’s PID and mold opening slope.

6. The temperature rises after the mold is installed and the pressure is tested, which makes it difficult to open the mold

After some time of mold loading and pressure test, the mold heats up and expands, and the clamping force increases, which makes it difficult to open the mold.

Pay attention to timely adjust the modulus to make the clamping force return to the original value to avoid mold opening failure.

7. After the mold is installed and locked, the downtime is too long, resulting in the inability to open the mold

After the mold is locked, the downtime is too long, resulting in the complete disappearance of the lubricating oil film of the machine hinge. The deformation of the machine hinge is further increased and the mold cannot be opened.

Therefore, reduce the downtime of the mold as much as possible. Remember to open the mold before shutting down and do not lock the mold in case of a shutdown.

8. Backpressure of mold opening, resulting in insufficient mold opening impulse

Setting the mold opening back pressure in the mold opening section of the oil circuit also results in insufficient mold opening impulse. If this situation is found, the mold opening backpressure is canceled.

9. The frictional resistance in the machine hinge is too large, which leads to mold opening resistance

(1) The edge of the oil groove in the steel sleeve is not deburred, causing the burrs to wear particles into the mating surface of the large pin shaft and the steel sleeve, causing the mating surface to wear or burn the mating surface.

To avoid this problem, it is required to process these parts. Remove burrs and smooth, check again during installation and clean up all surfaces and apply grease before installation.

(2) If there is insufficient lubrication or lubrication failure, it will also cause excessive friction resistance. At this time, check whether the lubricating oil circuit is normal and whether the lubricating pump is normal.

You may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept