How to simplify the hot runner system connections and avoid hot runner system assembly errors?

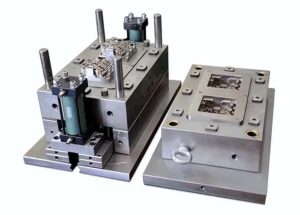

Although the hot runner and the injection mold are one and the same, however, its roles and functions are completely different compared to the injection mold itself. For the individual units that make up the runner system, there are special, high-precision positional requirements for their installation, connection, and operation.

For these reasons, the assembly of the system becomes a bottleneck for the injection mold installation. Therefore, avoiding errors during hot runner system installation as well as simplifying hot runner system connections and saving assembly time becomes a very important topic.

Conventional hot runner system design

Hot runner systems are derived from hot runner systems. Usually, the nozzle is not always mounted on the manifold but can be attached to the nozzle flange, but this type of system requires a fixed plate to keep the system in one piece. For most plastic processes, there is a temperature difference between the hot runner and the mold as the mold temperature approaches 200°C.

If the system is attached to the mold plate, it will raise the temperature and increase heat loss, and it may also create flow dead space between the manifold and the nozzle.

When the hot runner needs to be repaired, the hot sprue must be completely removed from the mold. Since the nozzles are not attached to the manifold, the electrical and hydraulic lines must be completely disconnected and reconnected after the service is completed.

Combination hot runner systems

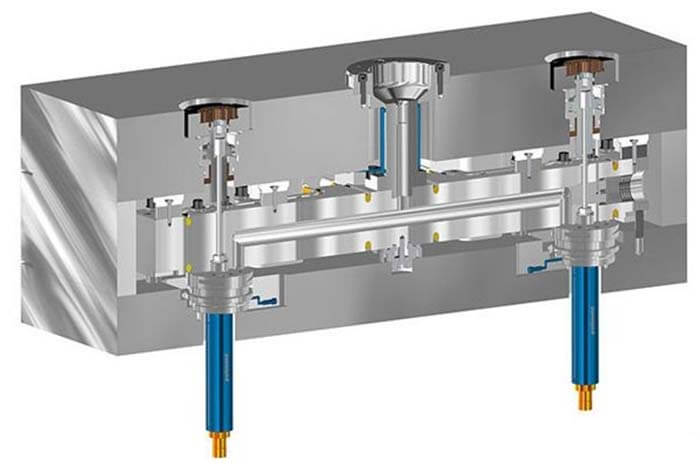

In a combined hot runner system, the nozzle and manifold form a simple unit. The melt flows directly from the manifold into the nozzle, so there are no deviations and no dead spots in the flow. Leakage between the nozzle and manifold is eliminated by the threaded nozzle being embedded in the manifold.

Conventional bushing system designs create a thermal expansion, and this combination system is particularly effective in eliminating such leakage.

The combination hot runner system is centrally located in the mold has minimal connections to the mold, and is manufactured from materials that do not require high thermal conductivity, clamping, and pre-tensioning of the mold sheet. This minimal connection provides high accuracy and a stable temperature profile, so the energy consumption is much lower than with conventional hot runner systems.

The combined hot runner system is able to be directly pre-assembled with a hydraulic line independent of the mold. Valve ports directly driven by hydraulic equipment can also be mounted directly on the system, thus eliminating the need for control valves on conventional machines and making injection molding more flexible.

In addition, the electrical, as well as hydraulic lines, can be configured according to the customer’s requirements. Since the system undergoes electrical, temperature, hydraulic, or pneumatic testing prior to delivery, the customer is provided with instructions for pre-installation of the system so that it can be easily installed in the mold and put into production immediately.

When the mold or system requires routine maintenance, the combined hot runner system can be removed from the mold in the same simple steps so that repairs and inspections can be performed independently of the mold.

Typically, combination hot runner systems reduce maintenance costs. The complete hot runner system is based on a combination of pre-assembled design and installation, where the heater or thermocouple wires are removed during assembly.

The wires connecting the heater to the distribution box are placed in a specially designed conduit, which is advantageous for the disassembly of either the mold or the hot runner system.

At the same time, the integrated hot runner system allows for disassembly-free routine maintenance, thus saving time and reducing the chance of assembly errors.

Besides the article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept