What is an injection molding hot runner system?

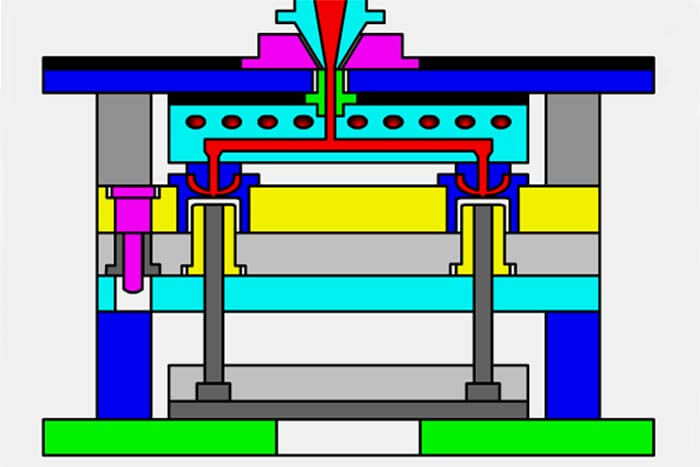

The hot runner system is a component of the injection molding system.

The hot runner system is generally composed of hot nozzles, manifolds, temperature control boxes accessories, etc. The hot nozzles generally include two types: open hot nozzles and needle valve hot nozzles. Needle valve hot runner system.

Hot runner technology is an advanced technology applied to the plastic injection mold casting hot runner system, which is a hot direction of plastic injection molding process development.

The so-called hot runner injection molding means that the plastic sent to the gate from the injector nozzle always remains molten and does not need to be cured and removed as scrap at each mold opening, and the molten material left in the casting system can be injected into the cavity during another injection.

The ideal injection molding system should form parts of uniform density, free from all runners, flanges, and sprues.

For a hot runner to do this, as opposed to a cold runner, the material must be maintained in a molten state within the hot runner and not be fed out with the molded part.

The hot runner process is sometimes referred to as a hot collector system or as runners molding.

Basically, the hot runner can be thought of as an extension of the barrel and nozzle of the injection molding machine. The function of the hot runner system is to deliver material to each gate in the mold.

What are the advantages of a combined hot runner system?

As a standard component of the mold system, the hot runner system can effectively improve the quality of plastic products, increase production efficiency, and provide a higher return on capital investment.

Now, a new type of combined hot runner system shines on the scene, and what surprises will it bring us?

Today, insert molding technology, co-injection molding technology, and multi-component injection molding technology all require the support of hot runners.

Many parts, such as car bumpers, can only be molded using hot runner molds due to flow path restrictions, wall thickness ratios, and fusion seam problems.

Hot runner systems are playing an increasingly important role in injection molding.

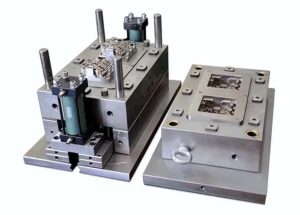

Although the hot runner and the injection mold are one and the same, however, its roles and functions are completely different compared to the mold itself.

For the individual units that make up the system, there are special, high-precision positional requirements for their installation, connection and operation.

For these reasons, the assembly of the hot runner system becomes a bottleneck for mold installation. Therefore, avoiding errors during hot runner system installation as well as simplifying system connections and saving assembly time becomes a critical topic.

How to install the hot runner system for injection molding?

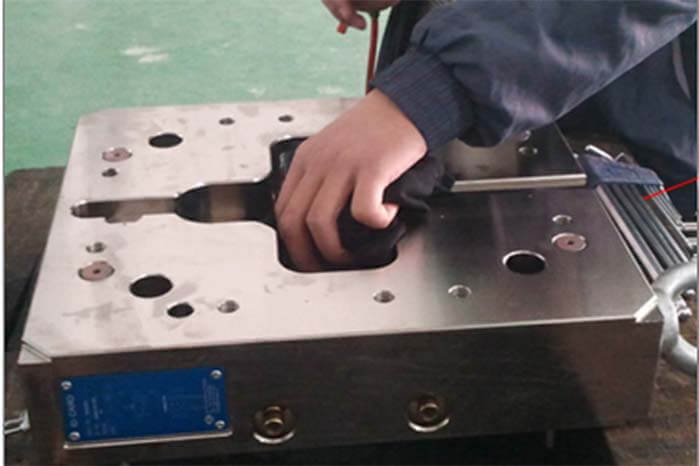

1) After checking the mold size and design drawings, spray the nozzle sealing surface and the nozzle installation reference surface with red dope in turn and install it into the mold.

After confirming the hot runner nozzle is in place, then take out the nozzle to see if the nozzle sealant surface and the rest of the surface fit in place. If the fit is not good or not in place find out the reason, if the fit is good then put the nozzle into the mold in turn and confirm that the fit is in place.

2) Measure the height of the nozzle above the mold A plate with a depth gauge, confirm that the height meets the requirements, insert the centre locating pin, stop rotating locating pin, and centre cushion, and put on the manifold, the manifold should be placed flat and stable, lock the manifold fixing screws.

3) Confirm the height of the support block on the manifold, (the general standard is on the gasket above the mold gasket 10 ~ 20 Division), meet the requirements, the manifold removed, the seal into the “O” ring groove of the thermal nozzle, and then put the manifold, lock the screws.

4) Use the number tube to number each group of wires on the thermal nozzle and manifold. Put the wire into the outlet slot and fix it with the pressure plate, confirm the length of the wire and cut off the excess wire, strip the wire and embed it into the terminal. After confirming the wiring method, fix the wire to the connector with the number in succession.

5) Use a multimeter to measure whether each group of lines is normal, then cover the mold cover and lock the cover screws. Put the connector into the junction box and fix it on the mold.

Application of Hot Runner Systems

Hot runner systems are a key component of multi-cavity injection molds. Conversely, hot runners are perhaps the least understood mold component from the mold manufacturer’s point of view. In reality, hot runner systems are complex and include various aspects of mechanical action, heating technology and precision manufacturing.

The successful application of hot runner systems in the injection molding environment requires a detailed analysis of the injection port design form, cavity geometry, resin and mold worker.

During the initial application analysis, the following questions should be evaluated.

(1) Can this part be molded using an injection molding press?

(2) Is the pressure of the injection molding machine sufficient to mold the part?

(3) Is the entire injection molding process reliable?

Application Analysis of Hot Runner Systems

The three main steps involved in the application analysis are computer-aided engineering analysis, resin testing, and the design of the hot runner system concept.

Four aspects of the use of hot runner system injection molding time

Hot runner molds are a new structure that replaces the runners of conventional molds or three-plate molds with runners that are heated at a constant temperature so that there is no need to remove the runner material each time the mold is made. We will discuss the timing of hot runner system use from the following four aspects.

Difference of mold structure

In order to mold oversized products, hot runners are required to make the plastic flow evenly, for example, automotive liners, appliance housings, etc., which require more simultaneous or time-sequential glue feeds.

For example automobile inner liners, home appliance shells, etc., it is necessary to feed glue in more places at the same time or in a time sequence.

When the glue is fed laterally away from the center of the injection molding machine, the glue feeding by the hot runner system will make the structure of the mold simple, easy to mold, accelerate the molding speed, reduce the molding time, have no material head, etc.

Disadvantages of three-plate mold

Three plate method in each injection, the heavy mother plate must slide on the guide pin, even if the new mold is difficult to use, the mold life is not long.

In each ejection, the amount of movement of the runner material from the mold is greater than the amount of movement of the template necessary to remove the molded part from the mold.

Conditions of using a hot runner system

When feeding from the ejector side, or when a long vertical runner is required.

This eliminates the problems caused by too long heads.

For large products or products that allow eccentric feeding.

In the case of three-panel molding, it is necessary to move the mother mold to remove the head. If the hot runner molding method is used, the mold opening movement can shorten the movement necessary to remove the head.

Hot runner systems can solve the problems of difficult objects such as high viscosity, low viscosity, and high molding temperature. Specific examples: metal powder injection, ceramic powder injection, plastic magnet injection, plastic bearing injection, thermoplastic rubber, etc.

In terms of saving plastic materials

Costs incurred by the cold head

As a simple example, if the cold head accounts for 68% of the scrap rate (in manufacturing, 1kg of material only produces 320g of product, while the remaining 680g is cold head). Although the cold material can still be recycled, due to the labour factor and the mix ratio of recycled material, some cold material must be accumulated to maintain normal operation, thus causing capital retention.

High-speed injection molding

High-speed injection molding not only improves molding efficiency, but is indispensable for the molding of cups, containers, and other thin and thick materials.

Laminated mold application

For some shallow and large quantity products, e.g. CD cases, and small pellet products, only a 15% increase in clamping force is needed to increase the output by 80% with the same injection time.

Environmental protection and efficiency of a hot runner system

Since hot runner is waste-free, hot runner system is a low-carbon product and does not produce factors that affect the environment.

It does not occupy the space of the storage head, with no noise of crushing and no deterioration problem.

Due to the wide variety of plastics, plus a variety of different colors, so often due to the accumulation of material head, must be sorted dehumidification, drying, sealing box storage. At the same time, the noise must be generated due to crushing affects the peace and a poorer working environment affects employee morale.

To sum up, we know that the three-plate die change to a hot runner system has the following advantages:

The material head is easy to take out and can reduce the travel of the material head;

The plastic flows more evenly during injection, and the operating conditions of each injection point can be controlled separately so that the plastic is easy to be injected;

Save plastic material cost and labour costs.

How to select hot runner systems for molds?

In order to eliminate or reduce the failure in use as much as possible, the following matters should be noted when selecting and applying hot runner systems.

The choice of heating method

Internal heating method:

The internal heating nozzle structure is more complex, has a high cost, is difficult to replace parts, and has high requirements for electric heating elements. The heater is placed in the middle of the runner, which will produce circular flow, increasing the friction area of the capacitor, and the pressure drop may be three times as much as the external heat nozzle.

Because the heating element of internal heating is located in the torpedo body inside the nozzle, all the heat is supplied to the material, so the heat loss is small and can save electricity. If a pointed gate is used, the tip of the torpedo body is kept in the center of the gate, which facilitates the cutting off of the gate after injection and makes the residual stress of the plastic part lower due to the late condensation of the gate.

External heating method:

The external heating nozzle can eliminate the cold film and reduce the pressure loss. At the same time, due to its simple structure, easy processing, and thermocouple installed in the middle of the nozzle so that the temperature control is accurate and other advantages, currently in production has been commonly used. But the external heat nozzle heat loss is greater than the internal heat nozzle energy saving.

Selection of gate form

The design and selection of the gate directly affect the quality of plastic parts. In the application of the hot runner system, the suitable gate form should be selected according to the flowability of resin, injection molding temperature, and product quality requirements, in order to prevent salivation, dripping, leakage,e and poor color change.

Temperature control method

After the gate form is determined, the control of melt temperature fluctuation will play a key role in the quality of plastic parts. Many times the scorching, degradation, or blockage of runners is caused by improper temperature control, especially for heat-sensitive plastics, which require a rapid and accurate response to temperature fluctuations.

For this reason, the heating element should be reasonably set to prevent local overheating, to ensure that the gap between the heating element and the runner plate or nozzle minimizes heat loss, and should try to choose the more advanced electronic temperature controller to meet the temperature control requirements.

The temperature and pressure balance calculation of each manifold

The purpose of the hot runner system is to inject the hot plastic from the nozzle of the injection molding machine, pass through the hot runner at the same temperature, and distribute the melt to each gate of the mold with balanced pressure.

Calculation of the nozzle and gate sleeve center offset due to thermal expansion. This means that the centerline of the hot (expanding) nozzle and the cold (non-expanding) gate sleeve should be aligned accurately.

Heat loss calculation

The internally heated runner is surrounded and supported by the cooled mold sleeve, so the heat loss due to heat radiation and direct contact (conduction) should be calculated as accurately as possible, otherwise, the actual runner diameter will be smaller due to the thickening of the condensation layer on the runner wall.

Installation of the hot runner plate

Both the thermal insulation and the injection pressure should be fully considered. Usually set up pads and supports between the runner plate and the template, which on the one hand can withstand the injection pressure, in order to avoid deformation of the hot runner plate and the phenomenon of material leakage, on the other hand, can also reduce heat loss.

Hot runner system maintenance

For the hot runner mold, the use of regular preventive maintenance of hot runner components is very important, this work includes electrical testing, sealing components connecting wire inspection, and cleaning of components’ dirty work.

Hot runner system color change technology considerations

Hot runner system injection molding is developed from the original open large spout to a cold runner to a needle valve to cold runner and further developed to needle valve flip-flop and direct pouring of glue on the inner surface of the product.

Hot runner technology is facing many problems: airlines, yellow lines on the gate, black lines, bright marks, shrinkage, and color change.

Application of hot runner system discoloration technology

Injection molding single product multiple color conversion

In injection molding production, often make a certain number of plastic parts of a certain color first, and then change to another color to continue production. Most companies will remove the front mold, disassemble the hot runner to clear the glue, and spend several hours of manpower idle injection molding machine.

This is where a quick color change hot runner is especially important. Without unloading the mold, directly start the hot runner color change procedure, and you can successfully change the color in about half an hour.

Intermittent injection molding of a single product

In the production process of injection molding orders, the mold is often unloaded after a certain number of production, waiting for the next batch of orders, and then the hot runner is heated during the production process.

At this time, a large amount of glue is usually needed to clean the degraded or yellow material in the runner and repeat the mold dozens of times for normal production, wasting labor and material raw materials. Using a hot runner system color change procedure, no need to empty injection glue, direct debugging injection molding machine 20 times, can be normal production.

Replacement of the same type of plastic in the hot runner system

Plastic parts of household electrical products, the same type also have different plastic. If the color is different, it is easy to have color differences and it takes a long time to adjust. If you use the hot flow channel color change program, you can simply solve this problem.

When gating yellow and black patterns inthe hot runner system color changing

White electric products often turn yellow or black near the gate. This is because the cutting fluid from the runner process burns carbon black at high temperatures and adheres to the runner walls a little at a time.

The color change hot runner system eliminates the masticating core structure, so there are no yellow lines. Black lines can be cleaned a dozen times before cleaning by the color change procedure.

Hot runner system color changes the basic conditions for success

- The hot runner system design is reasonable. The direction of the runner. The size of the hot runner is related to the pressure balance of the whole system and the flow direction of the plastic, which plays a decisive role in the success of color change. The hot runner system design should be integrated with theoretical calculations. From simulation analysis and practical experience to conclude.

- Dead-end structure treatment. Flow channel corners. A special structure must be used to avoid dead corners behind the valve pin and other places.

- Temperature control. Infrared photography of the actual temperature must be integrated with thermal analysis and correct control.

- Runner grinding and cleaning. To ensure the quality of the inner surface, no impurity residue.

- Excellent mechanical processing equipment.

- Special discoloration procedure.

Color change hot runner system design considerations

- It is not recommended to choose the whole wireframe system. Due to the large wireframe hot runner frame, the template is easy to deform, the product is easy to deform, the cost of wireframe hot runner is relatively high, and the cost of the mold is relatively high.

- It is recommended to design a beryllium copper (steel) inlay to carry water.

- When designing the point, control the flow length ratio of the point to prevent the flow length from being too long to cause heterochromia. Airlines and other bad appearance.

- Put the hot runner plate under the ejector push plate, extend the main nozzle, shorten the length of the hot nozzle, and reduce the pressure loss.

How to quickly achieve hot runner system color switching?

The simple method is to replace the hot runner system directly through the hot runner injection molding clean, but this method will waste a lot of raw materials, there is also through the runner air injection until the hot runner replacement is cleaned.

No matter which of these two methods is better in the process, it will take a lot of time and waste raw material. Because of the complex structure of the hot runner system and the many dead spots in the mold, it is not easy to replace the material slowly and cleanly by the flow of the material alone.

Now the entire thermoplastic market offers screw cleaning materials that can quickly and thoroughly clean the cleaning equipment screw and hot runner.

Material professional modification applicable temperature-wide and material-added additives in a certain temperature release of chemical additives can quickly decompose stubborn pigment, and destroy the original material molecular chain, from the metal surface. By soaking for a certain time to achieve geodetic cleaning.

Solving the hot runner system color transfer does not measure the ground, time, and material waste, according to effective data show that chemical screw cleaning material can save 70% of the cleaning time, and 70% of the material loss.

Injection molding hot runner vs cold runner system

What is the difference between a hot runner system and a cold runner?

Different in reference

Hot runner system:

It is a brand new structure that the sprue and runner of traditional mold or three plate mold are heated, and it is not necessary to take out the runner and sprue at each molding.

Cold runner system:

After cooling down in the mold and taking out the products, removing the cold material and trimming the pouring day can get the final products with no obvious traces of pouring.

The use of different

Hot runner system:

With different plastic characteristics, shapes, sizes, thicknesses, weights, cavity arrangements and gate positions, there are several different shapes and sizes of hot nozzles and runner plates on the market to suit various products.

Cold runner system:

Simple mold design, widely used.

Different characteristics

Hot runner system:

The plastic in the runner and gate is kept in a molten state by means of heating. Since there are heating rods and heating rings near or in the center of the runner, the whole runner from the nozzle outlet to the gate of the injection molding machine is in a high-temperature state, so that the plastic in the runner is kept molten, and it is generally not necessary to open the runner to take out the condensed material after shutdown.

Cold runner system:

The cold material produced needs to be crushed and recycled again.

Hot Runner System FAQ (problems and troubleshooting)

Hot Runner System Problem: No filling of the cavity

Cause: Melting temperature is too low; injection pressure is too low; the gate is too small; the hot nozzle is too small; mold temperature is too low; nozzle opening of melt cartridge is too small; the hot nozzle is clogged.

Solution: Increase the temperature of the hot nozzle and manifold, increase the injection pressure, enlarge the gate, increase the mold temperature, install a large-size hot nozzle, increase the melt cylinder outlet, and clear the blockage.

Hot Runner System Problem: Hot nozzle flow delay

Causes: Insufficient retraction (rewind), too high melting temperature, too large gate, insufficient cooling of the gate, and the incorrect type of hot nozzle.

Solution: Increase the amount of drawback, lower the hot nozzle temperature or mold temperature, choose the right nozzle, and process the correct gate size.

Hot Runner System Problem: The hot nozzle does not work correctly

Cause: The heating wire or thermocouple is defective, the hot nozzle is clogged, and the hot nozzle expansion is not calculated correctly.

Solution: Check/replace the heating wire, check/replace the thermocouple, clean the hot nozzle, recalculate, and process the expansion of the hot nozzle.

Hot Runner System Problem: Poor color change

Cause: Incorrect color operation procedure, incorrect thermal nozzle type.

Solution: Refer to the operating instructions for color change procedures and select the correct heat nozzle type.

Hot Runner System Problem: There are many flying edges on the product

Cause: High injection pressure, high temperature, poor flattening quality of the parting plate, insufficient clamping force.

Solution: Reduce the injection pressure, lower the hot nozzle/splitter/mold temperature, and increase the clamping force.

Hot Runner System Problem: Scorch marks on the product or in the gate area

Cause: Insufficient air venting on the mold, too fast injection speed, incorrect size of spout nest, insufficient drying of the material.

Solution: Increase the exhaust, reduce the injection speed, increase the “J” size on the nozzle nest size, and dry the material.

Hot Runner System Problem: The gate cools too early or starts to solidify in the middle of the processing cycle

Cause: Insufficient melt temperature, too small gate, excessive gate cooling, too large direct contact area between hot nozzle and fixed mold, incorrect gate profile, or incorrect gate type.

Solution: Increase the hot nozzle temperature, increase the temperature of the mold in the gate area, check the hot nozzle nest to ensure that the direct contact area is minimal, check the gate profile machining, and correct the gate profile if necessary.

Hot Runner System Problem: Cloudy pattern on the counterpart of the product

Cause: Mold is too cold, and melt temperature is not enough.

Solution: Increase the mold temperature and raise the melt temperature.

Hot Runner System Problem: Occasional cold material spots are extruded from the nozzle head of the core

Cause: Excessive heat loss from the head of the hot nozzle

Solution: Reduce the direct contact area of the head only to a minimum.

Hot Runner System Problem: Plastic sticks to the front of the bushing nozzle head and the direct nozzle head.

Cause: The contact area between the bushing nozzle head and the mold is not enough to dissipate heat.

Solution: Increase the contact area to enhance heat dissipation.

Hot Runner System Problem: The thermal manifold cannot reach the set temperature

Cause: Poor contact or failure of thermocouple, broken heating wire, heating wire wired too loose or too short.

Solution: Check whether the thermocouple contact is normal wiring is correct to check the heating wire circuit.

Hot Runner System Problem: The thermal manifold is too slow to heat up

Cause: A broken heating wire or wiring is too loose, insufficient air gap in the thermal manifold, excessive cooling on the heat insulation gasket, or poor thermocouple contact.

Solution: Check all heating wires, increase air gap, require at least 10mm, or use heat insulation plate, increase heat insulation plate on fixed die fixing plate (bottom plate) or lower the cooling on lower fixed die fixing plate, check if the thermocouple is good.

Hot Runner System Problem: The temperature of the thermal manifold is not stable

Cause: Poor thermocouple contact.

Solution: Check the thermocouple.

Hot Runner System Problem: Metal fragments in the melt

Cause: Debris on the injection molding machine screw, metal debris in the injection material

Solution: Remove the metal fragments to repair the impurities in the screw-filtered plastic.

Hot Runner System Problem: Leakage of material at the combination surface of hot manifold and hot nozzle

Cause: Incorrect calculation of expansion amount, inconsistent processing height of W surface, too soft material of fixed mold plate (bottom plate), too high temperature of hot manifold for a short time, a problem with the installation of “O” seal.

Solution: Recalculate and check the expansion amount, check the correct W surface height, replace the fixed plate (base plate) with the appropriate hardness, replace the damaged parts and “O” seal ring

Hot Runner System Problem: The thermal manifold compensation plug leaking rubber

Cause: No gasket.

Solution: Install the gasket.

Hot Runner System Problem: The oil (gas) cylinder does not work

Cause: No air / hydraulic oil in the cylinder, pneumatic/hydraulic cylinder system stuck, and the system pressure is not enough.

Solution: Check the pipeline and pump for leakage and blockage, and check the cylinder and piston to check if the feeding pipeline is excessively bent and if the piston and valve pin are flexible.

Hot Runner System Problem: The cylinder system is seized

Cause: Cylinder body, hot manifold, hot nozzle, etc. are not centered, fixed die fixed plate (bottom plate) accumulates too much heat.

Solution: Adjust the concentricity of the cylinder body, manifold, and hot nozzle to increase cooling around the cylinder body.

Hot Runner System Problem: The cylinder block overheated and stuck

Cause: Cylinder body, hot manifold, hot nozzle, etc. are not concentric, fixed die fixing plate (bottom plate) too much heat accumulation gasket and valve pin fixing nut friction.

Solution: Adjust the concentricity of the cylinder body, hot manifold, and hot nozzle, increase cooling around the cylinder body, and adjust the gasket and valve pin fixing nut

Hot Runner System Problem: Rubber leakage occurs around the valve needle bushing

Cause: The needle bushing on the heat manifold is too loose.

Solution: Check the diameter and height of the hole of the heat manifold and the bushing of the valve needle.

Hot Runner System Problem: Sticking material on the head of the valve pin

Cause: Too much heat is not emitted from the pin.

Solution: Reduce the temperature of the hot nozzle and gate and increase the cooling time.

Besides the What is A Hot Runner System In Injection Molding article, you may also be interested in the below articles.

Plastic Injection Molding vs. 3D Printing What’s the Difference?

Extrusion vs. Injection Molding, What Is The Difference?

Injection Molding vs. Thermoforming, What’s the Difference?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?