Engineering News

Provided By DGMF Mold Clamps Co., Ltd

Blog

We would like to share with you of everything about the plastic injection molding, CNC machining, stamping, pressing, die-casting, engineering technology.

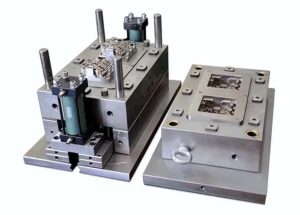

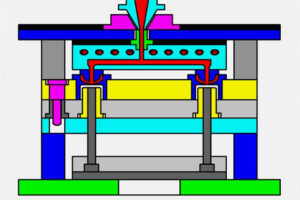

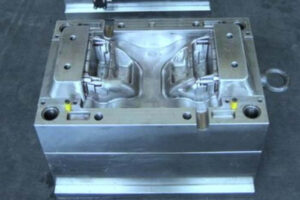

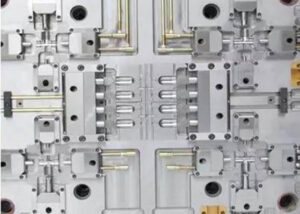

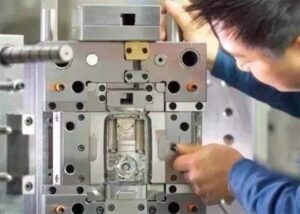

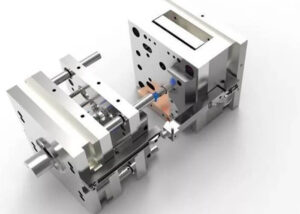

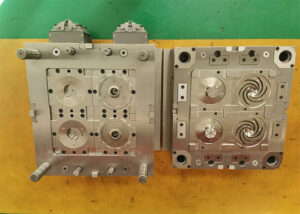

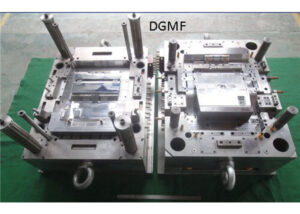

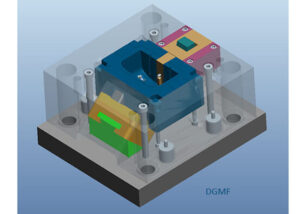

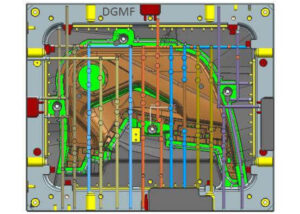

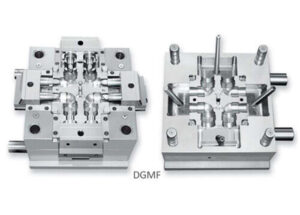

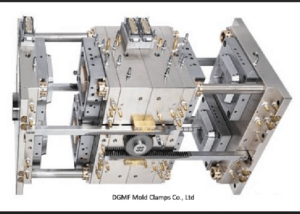

What is Mold-Making?

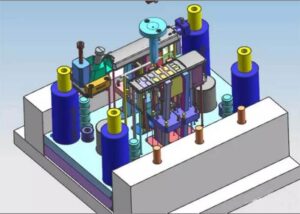

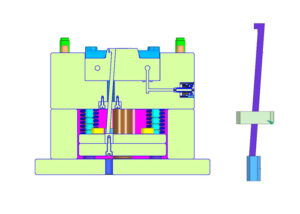

Mold-making processing What is Mold-making? Mold-making refers to the processing of molding and blanking tools, as well as shear dies and die-cutting dies. Typically, a

10 Different Types of Moulds

What are the different types of mould? There are many different types of moulds, which can be classified into various types according to different classification

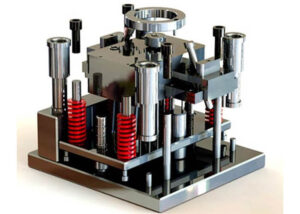

How to Improve the Durability of Stamping Dies?

After reading this How to Improve the Durability of Stamping Dies article, you will know about the 6 best ways to improve the durability of stamping dies. There

What Are The 5 Common Plastic Product Size Defects?

After reading this What Are The 5 Common Plastic Product Size Defects, you will know what the plastic product size defects are, what are the 5

9 Common Injection Molding Problems and Solutions

The main purpose of this 9 Common Injection Molding Problems and Solutions article is to discuss the causes of 9 common injection molding problems and how to

What is Porous Metal?

Porous metal meaning What is porous metal? Porous metal is a fine particle spherical powdered stainless steel sintered at high temperature and evenly covered with tiny

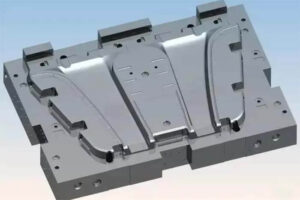

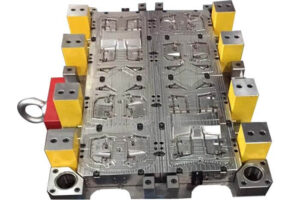

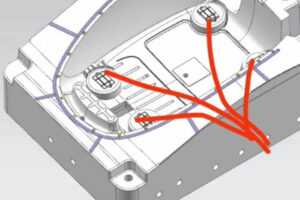

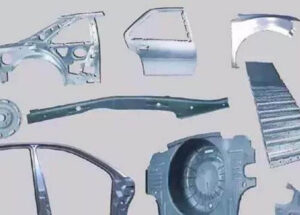

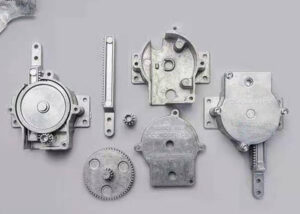

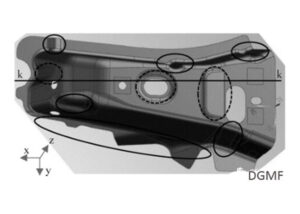

Stamping Die Design Fundamentals and Examples of Automotive Stampings

This Stamping Die Design Fundamentals and Examples of Automotive Stampings article guides us to understanding the fundamentals of die stamping. And examples of automotive stamping parts

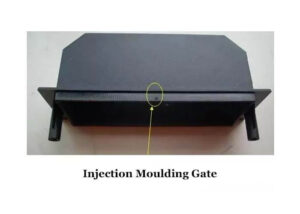

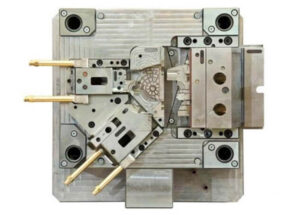

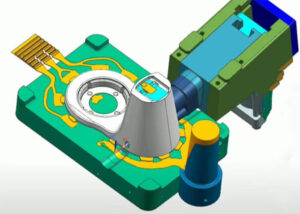

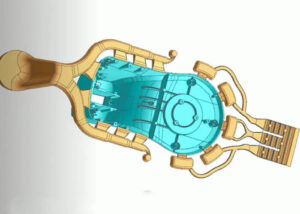

12 Types of Gates in Injection Moulding

This article discusses the 12 Types of Gates in Injection Moulding and how to select the right types of gates in injection moulding. What is an injection

Plastic Injection Mold Heat Treatment Process and FAQs

This Plastic Injection Mold Heat Treatment Process and FAQs article talks about plastic injection mold materials selections, plastic injection mold heat treatment features, plastic injection mold

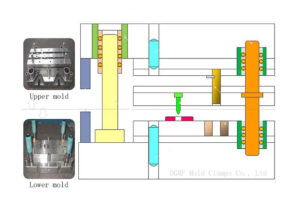

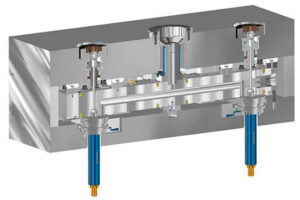

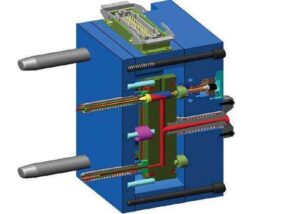

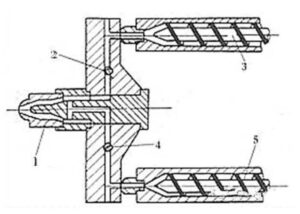

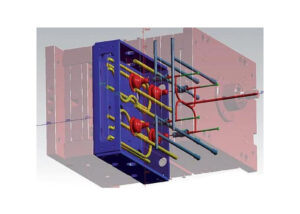

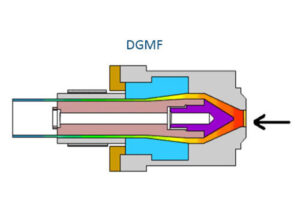

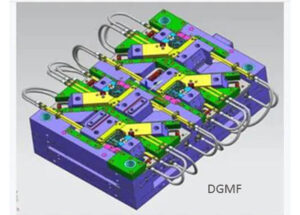

What is a Hot Runner System in Injection Molding?

What is an injection molding hot runner system? The hot runner system is a component of the injection molding system. The hot runner system is generally composed of

8 Ways to Improve Heat Treatment Deformation and Crack of Stamping Dies

There are many reasons affecting the heat treatment deformation and crack of stamping dies, mainly related to the original organization, the chemical composition of steel, the

What is a Cold Stamping Mold?

What is cold stamping? Cold stamping, also known as press working, is a manufacturing operation in which thermoplastics in sheet form are cold-formed using methods

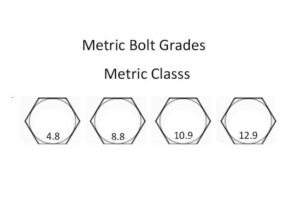

What are Metric Bolt Grades?

What are metric bolt grades indicated? The metric bolt grades are designated by a symbol of 2 numbers, separated by a decimal. The common metric bolt grades/classes are 4.8,

What is Deep Drawing?

What is deep drawing process? Deep drawing is a sheet metal drawing process method that uses a die to form sheet metal into an open

Plastic Injection Molding vs. 3D Printing, What’s the Difference?

After reading about Plastic injection molding vs. 3D printing, What’s the Difference; you will know: Plastic injection molding vs. 3D printing, What is the difference

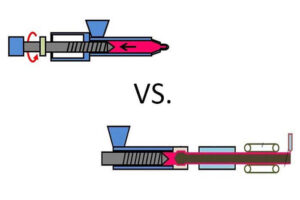

Extrusion vs. Injection Molding, What Is The Difference

After the read of Extrusion vs. Injection Molding, What Is The Difference, you will know: Extrusion vs. Injection Molding Principle Extrusion vs. Injection Molding Process Extrusion

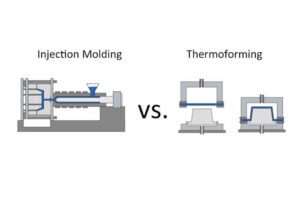

Injection Molding vs. Thermoforming, What’s the Difference?

After the read of Injection Molding vs. Thermoforming, you will know: Injection molding vs. thermoforming principle Injection molding vs. thermoforming advantages Injection molding vs. thermoforming types

30 Die-Stamping Problems And Troubleshooting

This article summarizes 30 die-stamping problems and troubleshooting for your reference. Die-Stamping Problems And Troubleshooting 1. The convex die wears too fast (1) The clearance of the

How to Choose the Injection Speed in Injection Molding?

Do you know how to choose the injection speed in injection molding? Control of the injection molding process directly impacts the quality of the final part and the

What are the 24 Different Types Of Metal?

This article introduces 24 different types of metal materials commonly used in machinery and mold processing and their characteristics! Different types of metal materials 1. 45# steel

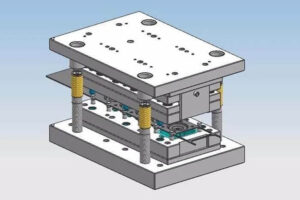

185 Injection Moulding Die Design Experiences

185 injection moulding die design experiences are precious information! Worth collecting. The 1 to 10 injection moulding die design experiences The height of the slider guide should be

85 FAQs of TPM Management

There are 85 FAQs of knowledge about TPM management, here we go! 1. What is TPM management? A: In terms of management, TPM (Total Productive Maintenance)

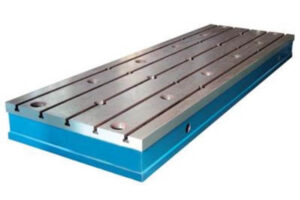

What is T-slot Bed Plate?

The T-slot bed plate, also called the T-slotted plate, is a kind of cast iron plate with a T-slotted surface used for assembly, debugging machinery, and equipment.

What is a Permanent Magnetic Chuck?

A permanent magnetic chuck, also known as a magnetic chuck, is a magnetic fixture widely used in machine shops, mold factories, and other machining fields, which

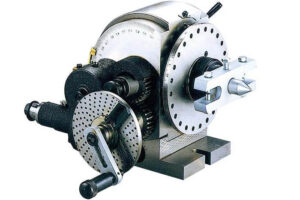

What is an Indexing Head?

An indexing head, also known as a dividing head or spiral head, is a specialized tool that allows a workpiece to be circularly indexed. The indexing dividing head

Top 10 Fixture Clamp Types In The Machining

The article talks about the top ten fixture clamps commonly used in the machining industry. Why fixture clamp is so important? Fixture clamps offer a wide assortment of style

What is Double-Color Injection Molding?

What is the double-color injection molding process? A double-color injection molding is a molding process in which two plastic materials are injected into the same injection molding machine and

30 Two-color Injection Molding Technical Info

If you know the 30 technical information on the two-color injection molding, the injection molding process will be done in helpful. What is two-color injection molding? Two-color injection

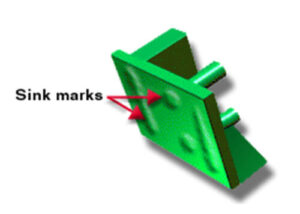

What Causes Sink Marks in Injection Molded Parts?

After the read, you will learn: What is the Sink Mark? What is the sink mark in injection molding? How do sink marks form? Why does the

18 Plastic Injection Molding Basics You Must Know

18 plastic injection molding basics that injection molding process personnel must know, do you know them all? Plastic injection molding basics 1. Injection nozzle The molten rubber usually

What are the Causes of Uneven Shrinkage in Plastic Parts?

Uneven shrinkage in plastic parts often results in uneven distribution of internal stress. If this stress exceeds the stiffness of the plastic part, it will cause

How To Solve Injection Mold Cooling Water Leakage Failure?

The injection mold cooling water leakage failure is mainly in the following aspects. Injection Mold Cooling Water Leakage Failure 1. The most occurring in the mold cooling water

What is the Understanding of the Injection Molding Process?

This article is from a senior process engineer, who shares some understanding of the injection molding process. Mold temperature of the injection molding process The mold

10 Problems and Solutions in Mold Trial

This article talks about the ten problems and solutions in injection mold trials. Here we go! A common problem in mold trial 1: Main sprue sticking

What is PBT Injection Molding Condition?

After the reading, you will know about what are the process conditions of PBT injection molding. With the rapid development of the plastics industry, new

What are the Effects of Injection Temperature and Speed on Product Shrinkage?

What is shrinkage in plastic molding? Shrinkage is the contraction of a plastic molded component as it begins to cool after the injection process. All plastics shrink as

9 FAQs on Injection Molding Process Optimization

Today, we talk about the list of questions and answers relating to the injection molding process optimization. If you have other injection molding process optimization methods,

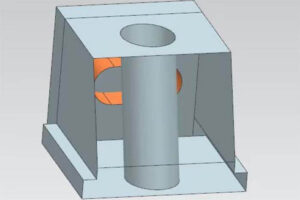

88 Common Mold Design Knowledge

Today, we talk about engineering concerning 88 common mold design knowledge points. Mold design knowledge 1. What are the commonly used plastic engineering materials and shrinkage

5 Ways How Hot Runner Molding Increases Efficiency

Why is hot runner molding so popular? Injection molding is the plastics manufacturing process of choice for major plastics-consuming industries, such as automotive and medical. In

16 Knowledge of Injection Molding Basics

After reading this 16 Knowledge collection of injection molding basics, you will learn the 16 listed knowledge collection of injection molding basics. Injection molding basics

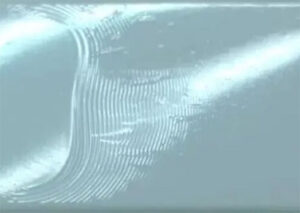

What is Flow Mark Injection Molding?

After reading this article, you will learn: What is the flow mark injection molding? How does the flow mark injection molding occur? How to solve

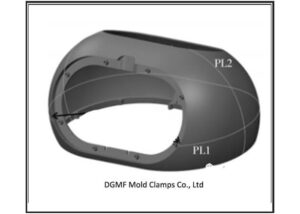

The 10 Principles of Mold Design Parting

Do you know the principles of mold design parting? Through communication with mold designers, we summarized the 10 main guidelines of the principles of mold

6 Big Tricks of Reduce Injection Mold Cost

What does the cost of injection mold cost? The injection mold cost is the mold material cost + processing cost + tax. Of course, there is also

8 Ways to Reduce the Cost of Injection Molding Processing

How to reduce the cost of injection molding processing? Here are eight ways to reduce the cost of injection molding processing, let us introduce the eight

How to Simplify the Hot Runner System Connection?

How to simplify the hot runner system connections and avoid hot runner system assembly errors? Although the hot runner and the injection mold are one and

What is the Melt Flow Index (MFI)?

What is the melt flow index? The melt flow index (MFI), known as the melt index, is a value that indicates the fluidity of plastic material during molding

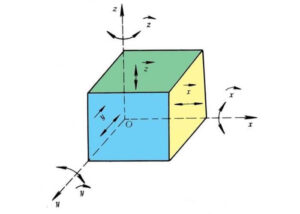

What is the 3-2-1 Principle of Location?

3-2-1 principle of location definition The 3-2-1 principle of location also called the six-point positioning principle, the 3-2-1 principle of location means that the workpiece has six

10 Advantages of Hot Runner System

What are the advantages of hot runner system in injection molding applications? Here we show you 10 advantages of the hot runner system and 4 disadvantages of the

What is the Polyethylene PE Material Plastic Injection Molding Process?

What is Polyethylene PE material plastic injection molding process? Polyethylene PE material is a typical thermoplastic, which is an odorless, tasteless, non-toxic, and flammable white

What are the 7 Plastic Injection Mold Polishing Techniques?

What is plastic injection mold polishing? Plastic injection mold polishing is a technique that helps to obtain smooth mold surfaces. It does this by removing

30 Notes for Making a Stamping Die

30 practical experience notes for making a stamping die work This article talks about the 30 notes for the design and production of making a stamping

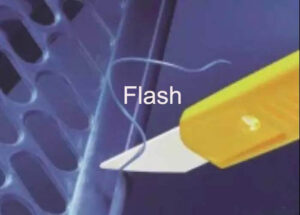

What Causes the Injection Molding Flash?

Analysis of the causes the injection molding flashes in injection molded products. What is an injection molding flash defect? Injection mold flash, or mold flashing,

The Theory of Injection Molding Processes

How much do you know about the theory of injection molding processes? Below are the 4 main Injection molding process theories. The viscosity of plastics and the influence

9 Factors Affect the Mold Cooling Rate

Here are the 9 factors affect the mold cooling rate of products in injection molding. 1. Plastic product design aspects affect the mold cooling rate

4 Injection Mold Maintenance Procedures

Injection mold maintenance is very important, what is the injection mold maintenance procedure? Here are the 4 injection mold maintenance procedures. As the most important injection

120 Lists of Injection Mold Acceptance Standards

The injection mold acceptance standard is recognized from the product quality, mold structure, injection molding process requirements, etc., accordingly, the injection mold quality is evaluated. In order to ensure

How to Adjust the Injection Molding Processes of Temperature, Pressure, and Speed?

After reading, you can learn about how to adjust the injection molding processes of temperature, pressure, and speed. How to adjust the injection molding process of

Technical Parameters of the Injection Molding Machine

What are the key technical parameters of the injection molding machine? Here we introduce some of the technical parameters of the injection molding machine. First, the

4 Aspects to Solve Injection-Molded Product Defects

How to solve injection-molded product defects? Here we have 4 aspects to solve injection-molded product defects. In the process of injection molding, carelessness can cause injection-molded

What Determines High-Performance Plastics?

What determines high-performance plastics? The following six factors determine high-performance plastics. The type of polymer determines high-performance plastics The performance is also different because of

What is Mold Clamp?

Mold clamp tools definition What is mold clamp? The mold clamp (also called mould clamp) is a kind of auxiliary clamping unit often used in injection mold processing,

4 Causes of Burn Marks in Injection Molding Parts

The common defects of injection molding parts include burn marks, and the causes of burn marks in injection molding parts are mainly four factors, namely melt

How to Solve the Deformation Problem of Flat Injection Molded Parts?

Today, we talk about the tips for solving the deformation problem of flat injection molded parts. The area of flat injection molded parts is large, and

Injection Moulding Process Optimization

What are the tips for injection moulding process optimization? How to optimize the injection molding process? The further development of injection molding equipment and the continuous improvement of product quality requirements

What is 2K Injection Molding?

Today, we talk about the 2K injection molding technology, a molding method in which two different colored plastics are injected into the same mold. 2K injection molding

9 Common Injection Molding Defects

This article mainly describes 9 common injection molding defects and the causes and solutions for these injection molding defects. Difficulty in gate stripping in injection molding defects

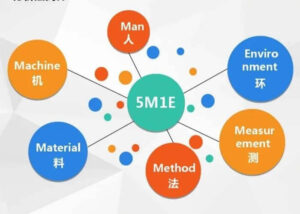

What is 5M1E in Injection Molding Industry?

Today, we talk about the 5M1E method in the injection molding industry. The six elements of on-site management are man, machine, material, method, environment, and measurement. That

How to Solve the Warpage Defect in Injection Molding of Thin-Walled Products?

What is a warpage defect in injection molding? Warpage defect in injection molding is one of the common defects in injection molding of thin-walled plastic parts.

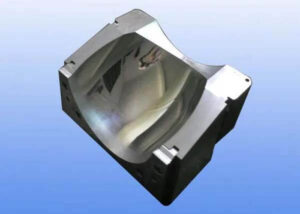

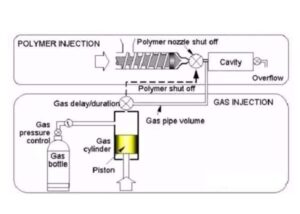

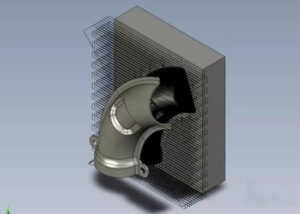

What is the Gas-Assisted Injection Molding Process?

Today, we are going to talk about the application of the gas–assisted injection molding process. The gas-assisted injection molding process utilizes the principle of high-efficiency pressure transmission

Mold Opening Force Insufficient Issue

This article mainly talks about the analysis and solution of the problem of the insufficient mold opening force of the injection molding machine. What should I do

Transparent Plastic Injection Molding Process

This article introduces the transparent plastic injection molding process. Here we go! The characteristics of commonly used transparent raw materials Due to the high light transmittance

Automotive Plastics Applications

Today, we are going to talk about automotive plastics, and the specific applications of engineering plastics in the automotive field. The main function of engineering automotive

What is Mold Temperature in Injection Molding?

The mold temperature in injection molding is probably the most important temperature in terms of quality and this affects quality in many ways. The mold temperature is

How to Improve Plastic Injection Molding Accuracy?

What is plastic injection molding accuracy and how to improve plastic injection molding accuracy? 1. Plastic Injection Mold processing quality includes processing accuracy and surface

TPR Plastic Material Injection Molding Process

This article talks about the TPR plastic material and TPR plastic material injection molding process. TPR plastic material According to the characteristics of the material and

BMC Moulding Process

Introduction to injection molding of thermoset BMC, the BMC moulding process. BMC is the abbreviation of glass fiber-reinforced unsaturated poly-cooled thermosetting plastic, and it is currently

8 Cost Control Methods for Injection Molding Factories

For the injection molding factories, the energy consumption of the injection molding process accounts for about 60%. Therefore, effectively reducing the energy consumption of the injection molding machine is

What is Guide Bush in Injection Mold?

What is guide bush? Guide Bush is used in conjunction with the guide pin and plays a guiding role. Generally, the clearance is very small, within 0.05mm. The guide

What are the Surface Treatment Processes for Plastic Products?

After reading the What are the surface treatment processes for plastic products article. You will learn the 14 surface treatment processes for plastic products. Nowadays,

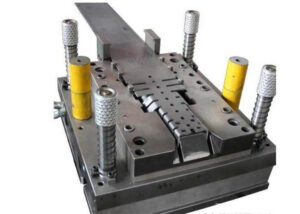

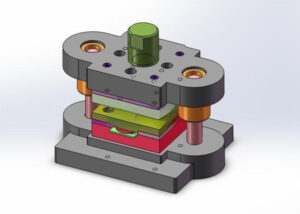

What are the Types of Stamping Dies?

Types of stamping die classifications Types of stamping die classified by process attributes Punching dies, bending dies, stretching dies, forming dies, and riveting dies are

6 Injection Mold Materials Selection Requirements

Why injection mold materials selection requirements are important? The selection of injection mold materials is a relatively important issue in injection mold design and injection mold

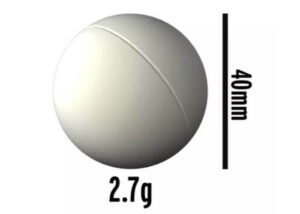

How is Table Tennis Made?

What is table tennis? Table tennis, also known as ping-pong and whiff-whaff, is a sport in which two or four players hit a lightweight ball,

How to do Stamping Die Maintenance?

Why is stamping die maintenance needed? To prolong the service life of the stamping die, stamping die maintenance and upkeep must be in place. Otherwise, it not

Mould Trial

What is mould trial? A mould trial is a process by which a new mould is optimized to produce the desired products as efficiently as

Hot Runner Mold

What is a hot runner mold? A hot runner mold is a mold that uses a heating device to keep the melt in the runner

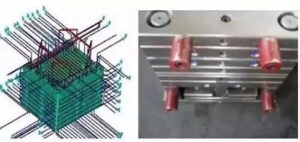

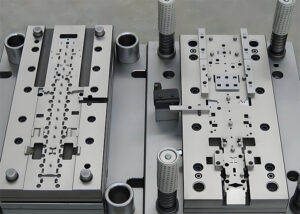

Progressive Stamping Die

What is progressive stamping die? Progressive stamping is a metalworking method that can encompass punching, coining, bending, and several other ways of modifying metal raw material,

Short-Shot Injection Molding

What is a short-shot injection molding? As the name implies, a “short-shot” is when the mold stops short of filling the mold cavity, leaving voids

How to Shorten the Injection Cycle?

What is the injection cycle? The injection cycle is the injection cycle of a hydraulically driven injection molding machine from the start of mold clamping to the next mold

Injection Mold Material Selection

What kind of material can make a good injection mold? How is the injection mold material selected? Injection mold is the mother of industry. Our

4 Problems of a Hot Runner of Injection Mold

After reading the 4 Problems of a Hot Runner of Injection Mold article. You will learn the four factors that cause the Hot Runner problems.

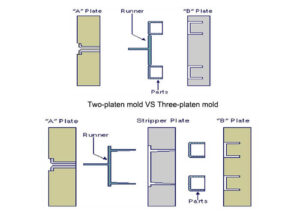

What is the Difference Between Two-Platen Mold and Three-Platen Mold?

What are the differences between two-platen mold and three-platen mold? After the read, you will learn about what is the difference between the two-platen mold

What Causes Bubbles In Injection Molding?

After reading the What causes bubbles in injection molding article. You will learn the three factors that cause the injection molding bubbles. What causes bubbles

Clamping Position of Injection Molding Machine

After reading the Clamping Position of Injection Molding Machine article. You will learn the three clamping positions of the injection molding machine. What are the

Injection Mold Hot Runner Technology

After reading the Injection Mold Hot Runner Technology article. You will learn the Injection Mold Hot Runner system information. What is injection mold hot runner?

Ten Factors to Improve Mold Quality

After reading the ten factors to improve mold quality article. You will learn the 10 different improve mold quality factors. The injection mold manufacturing process

How to do if Plastic Parts are Brittle in Processing

After reading the How to do if plastic parts are brittle in processing article. You will learn the three methods to solve it. What to

Gas-Assisted VS Water-Assisted Injection Molding

After reading the gas-assisted vs water-assisted injection molding article. You will learn what are the differences between them. Gas-assisted vs water-assisted injection molding, what is

What is Flash Injection Molding?

What is a flash injection molding? Flash, also known as overflow, flare, burr, etc., mostly occurs at the opening and closing positions of the mold,

5 Injection Molding Defect Solutions

What are the injection molding defects? The phenomena and solutions of various injection molding defects refer to the phenomenon and corresponding solutions of cracks, insufficient

How does Back Pressure Affect Injection Molding?

How back pressure affects injection molding? The back pressure during pre-molding indicates the pressure in the metering chamber of the screw during pre-molding. Back pressure

How to Solve Lusterless Injection-Molded Plastic Parts?

After reading this How to solve lusterless injection-molded plastic parts article. You will learn about what are lusterless injection-molded plastic parts and how to solve

What are Injection-Molded Parts?

This article talks about what are injection-molded parts and how they form. Enjoy it. What are injection-molded parts? Injection-molded parts refer to various injection-molded products

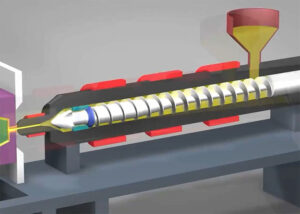

What is Injection Molding?

After the read, you will learn about: What Is Injection Molding and Injection Processes. Temperature control Mold temperature Molding cycle Process elements of molding Back

How to Form Injection Back Pressure?

What is injection back pressure? Injection back pressure is one of the important parameters for controlling melt quality and product quality in the injection molding

How to Solve the Poor Exhaust of Injection Molded Parts?

After reading the How to solve the poor exhaust of injection molded parts article. You will learn the 13 problem causes and solutions. The exhaust

4 Parameters in Designing Injection Molds

After the reading, you can learn the 4 parameters in designing injection molds. Injection volume Clamping force Tie rod spacing Nozzle size check There are

Eight Categories of Injection Molds

After the read, you will learn about the following eight categories of injection molds. Single-parting surface injection mold Double-parting surface injection mold Injection mold with

9 Problems that Often Occur in Injection Molds

The 9 problems that often occur in injection molds article talks about the causes of 9 problems that often occur in injection molds and the

How to Design the Location of the Mold Gate?

After reading the How to Design the Location of the Mold Gate article. You will learn what is an injection mold gate and how to

How to Determine the Air Vents of Thin-Walled Molds?

After the read of How to Determine the Air Vents of Thin-Walled Molds article, you will learn about: Air vents method Design method Design size

How To Design Injection Molding Product?

This article on how to design injection molding products introduces some basic principles of injection molding product design and mold design. Reasonable product design and

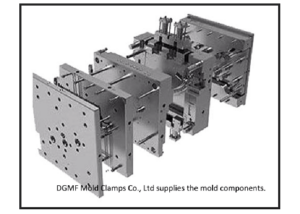

The Name and Function of Mold Components

What are mold components? Mold components refer to the general name of metal accessories used in stamping dies, plastic molds, or FA automation equipment exclusively

18 FAQ of Injection Molding Machine Mold Clamping

This article summarizes 18 FAQs about injection molding machine mold clamping failure analysis and repair. I hope it can help those in need. If there

Auto Parts Stamping Die Design Concept

Process parts, such parts directly participate in the completion of the process and have direct contact with the blank, including working components, positioning components, unloading and

Molds Overview

After reading the Molds Overview article. You will know about Various molds and molding tools. Various molds and molding tools Molds, various molds, and tools

What is An Injection Molding?

Injection molding meaning What is an injection molding? Injection molding is an injection and molding method. Injection molding is a manufacturing process for producing parts

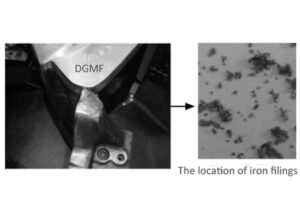

How To Solve The Iron Filings Produced By Stamping Die?

Why need to solve the iron filings produced by stamping die? In the production process of stamping parts, the main problems that affect the production

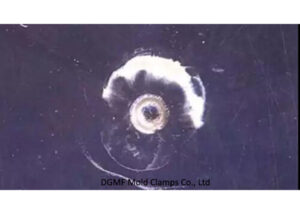

How To Solve The Defect In The Product Gate Area?

After reading this How To Solve The Defect In The Product Gate Area article. You will get the answer to solve the defect in the

What is an Overmold?

After the read, you will learn about: What is an overmold? The difference between plastic over mold and two-color mold What are the problems that

How To Make A Silicone Rubber Mold?

After the read of this How To Make A Silicone Rubber Mold article. You will know the silicone rubber mold manufacturing method and precautions How

How To Install The Stamping Die?

After the read of how to install the stamping die article. You will know the correct way to install and remove the die molds. Install

How To Improve The Mold Trial Success Rate?

After reading the article. You will learn about: Why do we need to improve the mold trial success rate? How to improve the mold trial

Summary of 50 Injection Mold Structure Operation Dynamic Diagrams

Molds play an important role in the industry, and a large number of industrialized products are inseparable from molds. Regardless of all walks of life,

How to Solve Flow Lines in Injection Molded Products?

This article talks about the Analysis and countermeasures of flow lines in injection molded products. Analysis and countermeasures of flow lines in injection molded products

How to Deal With Sink Marks on the Surface of Injection Molded Products?

After reading the How to Deal With Sink Marks on the Surface of Injection Molded Products article. You will know the problems and answers to

What is the Reason for the Sticking of the Runner?

After reading the What is the Reason for the Sticking of the Runner article. You will know the causes of sticky mold in the runner.

Basic Requirements for Plastic Injection Molded Part Design

After reading the basic requirements for plastic injection molded part design article. You will know the plastic injection molded part design basic requirements. Why requirements

6 Polishing Methods for Plastic Injection Molds

After reading 6 Polishing Methods for Plastic Injection Molds article. You will know the 6 common plastic injection mold polishing methods. Why do plastic injection

10 Plastic Injection Molding Methods

After reading 10 Plastic Injection Molding Methods article. You will know the 10 common plastic Injection molding methods. Plastic products are made of a mixture

What Is Cold Forging?

After reading What is Cold Forging article. You will know cold forging meaning, applications, and technologies, etc. What is cold forging meaning? Cold forging, cold

What Is Blow Molding?

After reading What is blow molding article. You will know what is blow molding, blow mold, and its applications, etc. What is blow molding meaning?

What is the Difference Between Blow Molding and Injection Molding?

After reading the What is the Difference Between Blow Molding and Injection Molding article. You will know about the 3 differences between blow molding and

Nine Steps of Stamping Die Design

After reading the Nine Steps of Stamping Die Design article. You will know about the 9-core stamping die design steps. What is a stamping die?

Stamping Die Data Summary

After reading the Stamping Die Data Summary article. You will know 17 different data in the stamping die molds Stamping Die Data 1. Information is

17 Common Problems and Solutions for Stamping Dies

This 17 Common Problems and Solutions for Stamping Dies article summarizes 17 common problems of stamping dies and lists some solutions for your reference. Common

What Affects The Cooling Efficiency of The Mold?

After reading this What Affects the Cooling Efficiency of the Mold article. You will know the three main matters that affect the cooling efficiency of

Various Inclined Top Ejection Structures of Injection Mold

This article analyzes various inclined top ejection structure mechanisms of injection molds, Explains their respective advantages and disadvantages, and has a certain guiding role for

Specification for Installation and Adjustment of Plastic Injection Molds

After reading this specification for installation and adjustment of plastic injection molds article. You will learn 6 main points of installation and adjustment of plastic

6 Elements Of An Aluminum Extrusion Die Design

After reading the Six Elements of an Aluminum Extrusion Die Design article. You will know the six elements that affect the aluminum extrusion die design.

What Should I Pay Attention To In The Production Of Plastic Molds

After reading What should I pay attention to in the production of plastic Molds article. You will know 19 items needed for plastic mold making.

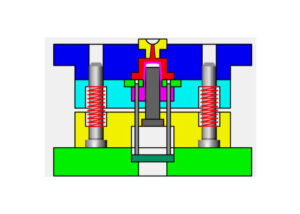

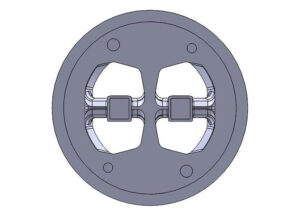

One-Die Double-Punch Compound Die

This article is to share one-die double-punch compound die technology. Enjoy it. One-die double-punch compound die technology The structure exploration and manufacturing process analysis of

Mold Principle

What is a mold principle? The mold principle is a tool or device that processes raw materials into a desired shape and size using a

How To Design A Plastic Cover Injection Mold?

After the read of this how to design a plastic cover injection mold. You will know about: The comparison of the mold structure of plastic

How To Design An Injection Mold Cooling System?

After the read of this article. You will learn about how to design an injection mold cooling system and the factors that affect the cooling

How Mold Temperature Affects Quality Control Of Injection Molded Parts?

After the read this article, you will know how mold temperature affects quality control of injection molded parts. How a mold temperature affects quality control

14 Measurement Geometric Tolerance Of Injection Molding

After the read of this 14-Measurement Geometric Tolerance Of Injection Molding. You will know about the 14 methods of measurement geometric tolerance of injection molding.

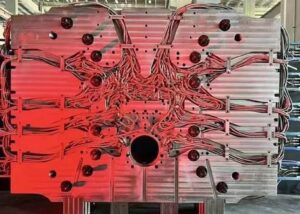

Design Of Stamping Process Of Automobile-Reinforced Cover

How design of stamping process of automobile-reinforced cover? In the design of stamping process of automobile-reinforced cover molds with large external dimensions, small material thickness,

Design Ideas And Steps Of Aluminum Extrusion Die

What are the design ideas and steps of aluminum extrusion die? Here are three design ideas and steps of aluminum extrusion die. After the read

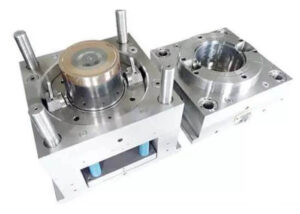

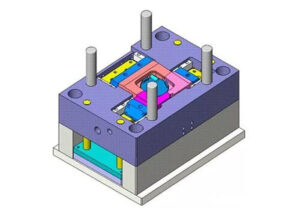

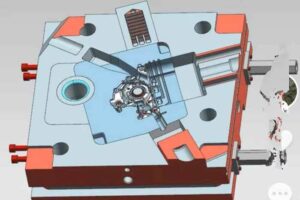

Construction Of Injection Mold

What is the construction of injection mold? The plastic mold is composed of two parts, a movable mold and a fixed mold. The movable mold

Application And Process Of A Gas-Assisted Injection Molding Process

Application and process of a gas-assisted injection molding processing After the read of this article, you will learn about the application and process of a

7 Overlooked Aspects Of Injection Mold Maintenance

The 7 overlooked aspects of injection mold maintenance The maintenance procedures required for each injection molding location depend on different injection mold cycle cycles. The

Die-Casting Mold VS Plastic Injection Mold

Die-casting mold vs plastic injection mold, what is the difference? What is the difference between die casting mold and plastic mold? The injection molding pressure

How To Change The Color On Hot Runner?

Any plastic injection mold manufacturer that needs frequent color changes will consider using color change technology. If the high-volume hot runner system does not have

How Does The Mold Temperature Affect The Product?

How does the mold temperature affect the products? In our usual production process, when some products are relatively small and the requirements are not very

Structural Design Of Injection Mold For Concave Inner Shell

What is the structural design of injection mold for concave inner shell? Through the structural analysis of the plastic injection molded parts of the internal

Is The Mold Clamp In The Tools Design A Standard Part?

Do you think, is the mold clamp in the tools design a standard part? And why or why not? A mold clamp in the tools

What Are Pre-Molding Action And Back Pressure Control For Injection Molding?

What are pre-molding action and back pressure control for injection molding you know? The pre-molding action and back pressure control for injection molding Choice of

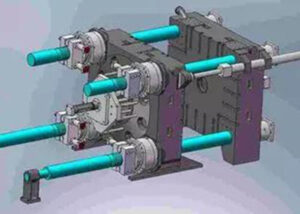

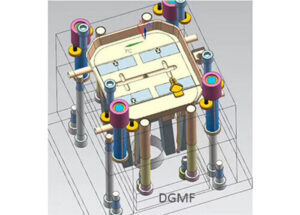

What Are The Design Standards For Injection Stack Molds?

Before knowing what are the design standards for injection stack molds. We should learn about what is a stack mold. What is injection stack mold?

What Are The Processes Of Injection Mold Design?

There are the 6 processes of injection mold design In general, the injection mold design has the following six main overall design processes. The

What Is A Die-Casting Mold?

Do you what Is a die-casting mold? Die-casting mold is a tool for casting metal parts, a tool for completing the die-casting process on die-casting

What Is The Hydraulic Working Principle Of The Injection Molding Machine?

After the read of this What Is The Hydraulic Working Principle Of The Injection Molding Machine article, you will learn: What is Hydraulic? Advantages and

What Is An Under-Injection?

Under-injection Refers To The Phenomenon That The Plastic Injection Material Does Not Completely Fill The Injection Mold Cavity.

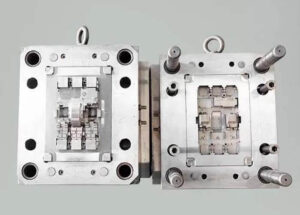

What is the Injection Mold Structure?

Plastic injection mold structures can be divided into static and dynamic molds. Generally speaking, the injection mold structure consists of seven parts. Pouring system injection mold structure