Transparent Plastic Injection Molding Process

This article introduces the transparent plastic injection molding process. Here we go! The characteristics of commonly used transparent raw materials Due to the high light transmittance of transparent plastics, the surface quality of plastic products must be strict, and there must be no spots, pores, whitening, haze, black spots, discoloration, poor gloss, or other defects. Therefore, […]

Automotive Plastics Applications

Today, we are going to talk about automotive plastics, and the specific applications of engineering plastics in the automotive field. The main function of engineering automotive plastics used in automobiles is to make automobiles lighter, so as to achieve the purpose of fuel-saving and high speed. Developed countries regard the amount of plastic used in automobiles […]

What is Mold Temperature in Injection Molding?

The mold temperature in injection molding is probably the most important temperature in terms of quality and this affects quality in many ways. The mold temperature is not the same thing as the cooling water temperature, it is the temperature of the actual mold cavity after it has stabilized. The setting of mold temperature in injection molding […]

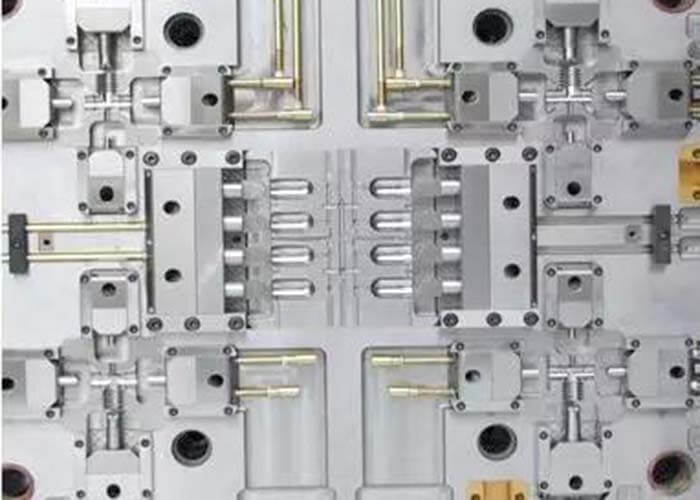

How to Improve Plastic Injection Molding Accuracy?

What is plastic injection molding accuracy and how to improve plastic injection molding accuracy? 1. Plastic Injection Mold processing quality includes processing accuracy and surface quality Machining accuracy is the degree of conformity between the actual size, shape, and position of the three geometric parameters of the surface of the processed part and the ideal […]

TPR Plastic Material Injection Molding Process

This article talks about the TPR plastic material and TPR plastic material injection molding process. TPR plastic material According to the characteristics of the material and the supply situation, the appearance and process performance of the material should be tested before injection molding. The pellets supplied often contain varying degrees of moisture, solvents, and other volatile low-molecular-weight […]

BMC Moulding Process

Introduction to injection molding of thermoset BMC, the BMC moulding process. BMC is the abbreviation of glass fiber-reinforced unsaturated poly-cooled thermosetting plastic, and it is currently the most widely used type of reinforced thermosetting plastic. Features and applications of BMC BMC has good physical, electrical, and mechanical properties, so it has a wide range of applications, […]

8 Cost Control Methods for Injection Molding Factories

For the injection molding factories, the energy consumption of the injection molding process accounts for about 60%. Therefore, effectively reducing the energy consumption of the injection molding machine is an important way to save energy in the injection molding factories. With the continuous improvement of the energy-saving technology of the injection molding machine itself, reducing the overall energy consumption […]

What is Guide Bush in Injection Mold?

What is guide bush? Guide Bush is used in conjunction with the guide pin and plays a guiding role. Generally, the clearance is very small, within 0.05mm. The guide pin and guide bushing are injection mold components generally used in injection molds or some machinery to ensure the accuracy of movement. Guide bush function The guide bushing in the injection mold plays […]

What are the Surface Treatment Processes for Plastic Products?

After reading the What are the surface treatment processes for plastic products article. You will learn the 14 surface treatment processes for plastic products. Nowadays, plastic products are ubiquitous, but the functional requirements of people in today’s life for plastic products are not as easy to use as before. Now the appearance must not only […]

What are the Types of Stamping Dies?

Types of stamping die classifications Types of stamping die classified by process attributes Punching dies, bending dies, stretching dies, forming dies, and riveting dies are classified according to process performance. Blanking dies: A die that separates materials along a closed or open outline. Such as blanking dies, punching dies, cutting dies, slitting dies, trimming dies, […]