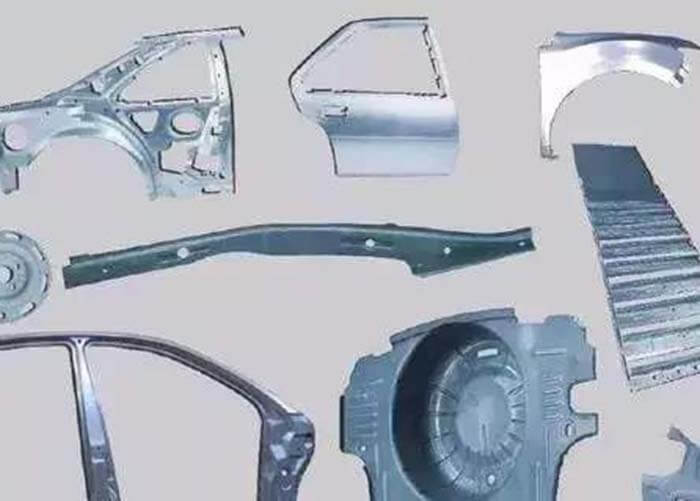

30 Notes for Making a Stamping Die

30 practical experience notes for making a stamping die work This article talks about the 30 notes for the design and production of making a stamping die and the experience in practical making a stamping die work. Here we go! Making a stamping die note 1 Before planning the strip, it is important to understand the public service […]

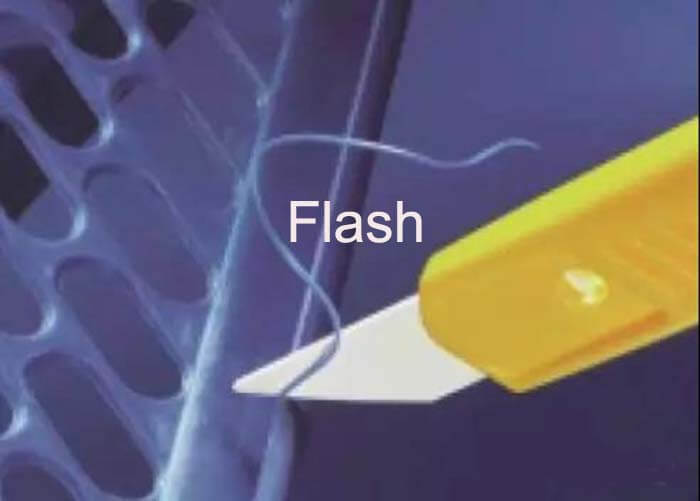

What Causes the Injection Molding Flash?

Analysis of the causes the injection molding flashes in injection molded products. What is an injection molding flash defect? Injection mold flash, or mold flashing, is excess plastic that forms on the surface of injection molded parts. This unwanted material is usually forced out of the injection mold cavity at the parting line but can also emerge […]

The Theory of Injection Molding Processes

How much do you know about the theory of injection molding processes? Below are the 4 main Injection molding process theories. The viscosity of plastics and the influence of conditions on viscosity theory of injection molding process When the molten plastic flow between the large molecules of the nature of mutual friction is called plastic viscosity, and the […]

9 Factors Affect the Mold Cooling Rate

Here are the 9 factors affect the mold cooling rate of products in injection molding. 1. Plastic product design aspects affect the mold cooling rate The main one is the wall thickness of the plastic product. The greater the thickness of the product, the longer the cooling time. In general, the cooling time is approximately proportional to […]

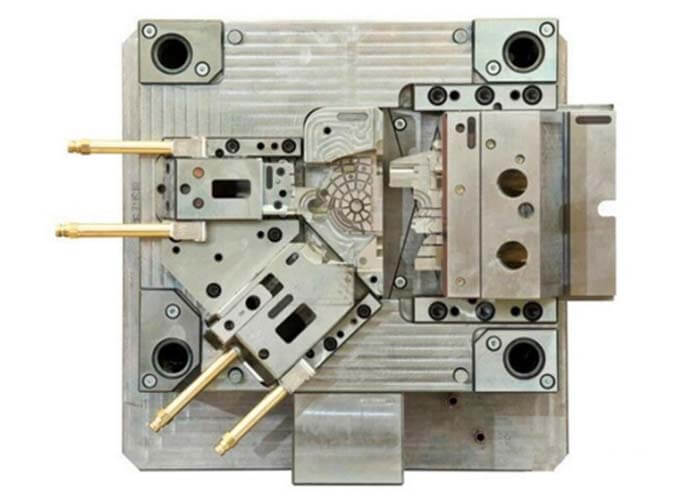

4 Injection Mold Maintenance Procedures

Injection mold maintenance is very important, what is the injection mold maintenance procedure? Here are the 4 injection mold maintenance procedures. As the most important injection molding equipment for the processing of injection molded products, the quality of the injection mold is directly related to the quality of the products. As injection molds account for a […]

120 Lists of Injection Mold Acceptance Standards

The injection mold acceptance standard is recognized from the product quality, mold structure, injection molding process requirements, etc., accordingly, the injection mold quality is evaluated. In order to ensure that the injection mold can produce qualified products, it is normal to invest in production, ensuring the production life of the mold meets the production requirements of product design. The […]

How to Adjust the Injection Molding Processes of Temperature, Pressure, and Speed?

After reading, you can learn about how to adjust the injection molding processes of temperature, pressure, and speed. How to adjust the injection molding process of temperature? Injection molding temperature measurement and control are very important in injection moulding. Although these measurements are relatively simple, most injection molding machines do not have sufficient temperature tights or lines. At […]

Technical Parameters of the Injection Molding Machine

What are the key technical parameters of the injection molding machine? Here we introduce some of the technical parameters of the injection molding machine. First, the technical parameters of the injection molding components (1) Screw diameter: outer diameter size of the screw (2) Screw effective length: The length (mm) of the thread on the screw is often used […]

4 Aspects to Solve Injection-Molded Product Defects

How to solve injection-molded product defects? Here we have 4 aspects to solve injection-molded product defects. In the process of injection molding, carelessness can cause injection-molded product defects, how to prevent injection-molded product defects? 4 ways to solve injection-molded product defects To solve injection-molded product defects, there are many methods. Today, we do the 4 aspects of the […]

What Determines High-Performance Plastics?

What determines high-performance plastics? The following six factors determine high-performance plastics. The type of polymer determines high-performance plastics The performance is also different because of the different polymer links, such as acetal resin (POM) impact strength, then the unsaturated polyester resin (UP) is more excellent. Even if the same material, structure, and polymerization degree are […]