What is Flow Mark Injection Molding?

After reading this article, you will learn: What is the flow mark injection molding? How does the flow mark injection molding occur? How to solve the flow mark troubleshooting in injection moulding? Flow mark injection molding in plastic 1. Poor flow Flow Length to Thickness Ratio A large cavity must be filled with easy-to-flow plastic. […]

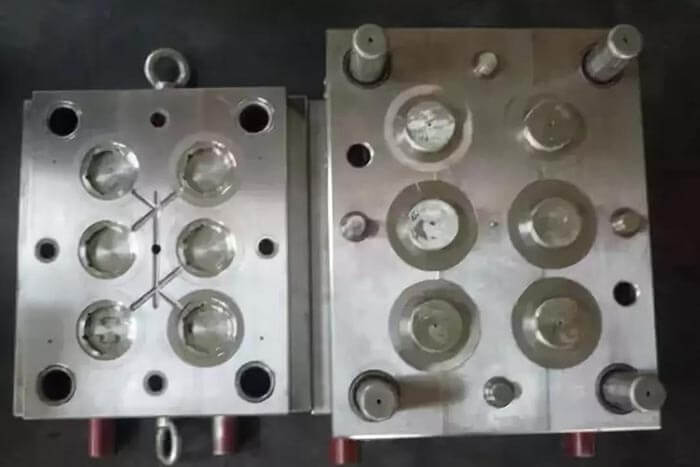

The 10 Principles of Mold Design Parting

Do you know the principles of mold design parting? Through communication with mold designers, we summarized the 10 main guidelines of the principles of mold design parting. Although these guidelines in mold parting design may not all meet, or even conflict, they do put forward from different aspects of the mold design parting surface design […]

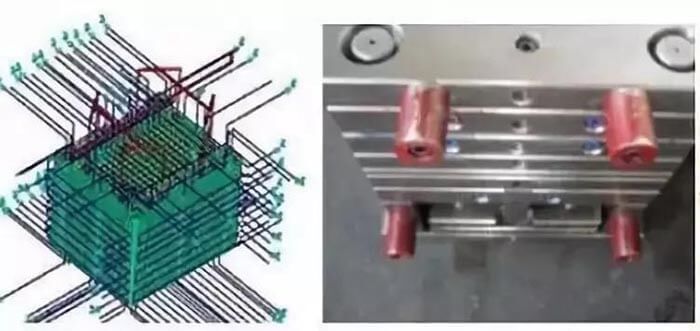

6 Big Tricks of Reduce Injection Mold Cost

What does the cost of injection mold cost? The injection mold cost is the mold material cost + processing cost + tax. Of course, there is also labor cost, we can think that labor cost is included in the processing cost, of course, there is also the design cost. First, whether the product is reasonably designed will […]

8 Ways to Reduce the Cost of Injection Molding Processing

How to reduce the cost of injection molding processing? Here are eight ways to reduce the cost of injection molding processing, let us introduce the eight ways to reduce the cost of injection molding processing one by one. I. How to reduce the cost of injection molding processing in the production workshop? The layout of the […]

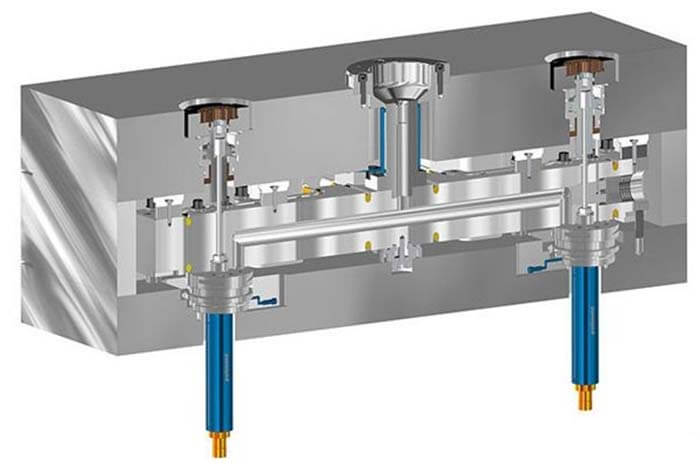

How to Simplify the Hot Runner System Connection?

How to simplify the hot runner system connections and avoid hot runner system assembly errors? Although the hot runner and the injection mold are one and the same, however, its roles and functions are completely different compared to the injection mold itself. For the individual units that make up the runner system, there are special, high-precision […]

What is the Melt Flow Index (MFI)?

What is the melt flow index? The melt flow index (MFI), known as the melt index, is a value that indicates the fluidity of plastic material during molding processing. The melt flow index (MFI) is a measure of the ease of flow of the melt of a thermoplastic polymer. It is defined as the weight of the polymer […]

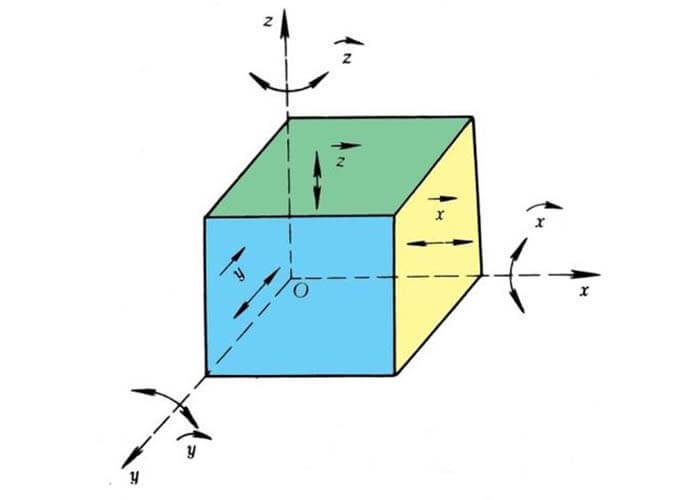

What is the 3-2-1 Principle of Location?

3-2-1 principle of location definition The 3-2-1 principle of location also called the six-point positioning principle, the 3-2-1 principle of location means that the workpiece has six degrees of freedom in space, i.e., the freedom of movement along the three right-angle axes of x, y, and z, and the freedom of rotation around the three axes. To […]

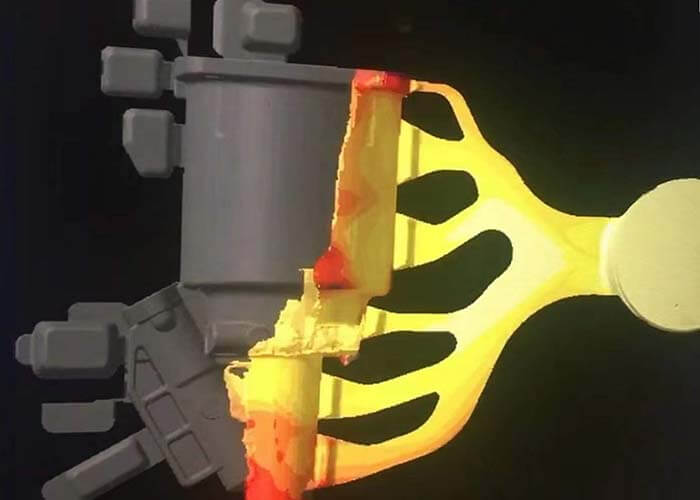

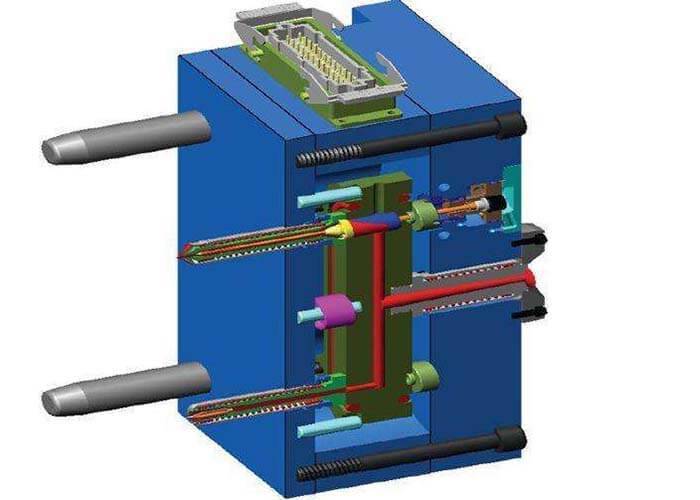

10 Advantages of Hot Runner System

What are the advantages of hot runner system in injection molding applications? Here we show you 10 advantages of the hot runner system and 4 disadvantages of the hot runner system. Hot runner mold system structure is roughly the same as a fine sprue, the biggest difference is that the hot runner injection molding is in one or more hot […]

What is the Polyethylene PE Material Plastic Injection Molding Process?

What is Polyethylene PE material plastic injection molding process? Polyethylene PE material is a typical thermoplastic, which is an odorless, tasteless, non-toxic, and flammable white powder. Polyethylene PE material for the molding process is extruded and granulated waxy granule material with a milky white appearance. Its molecular weight is in the range of 10,000 to 100,000. The […]

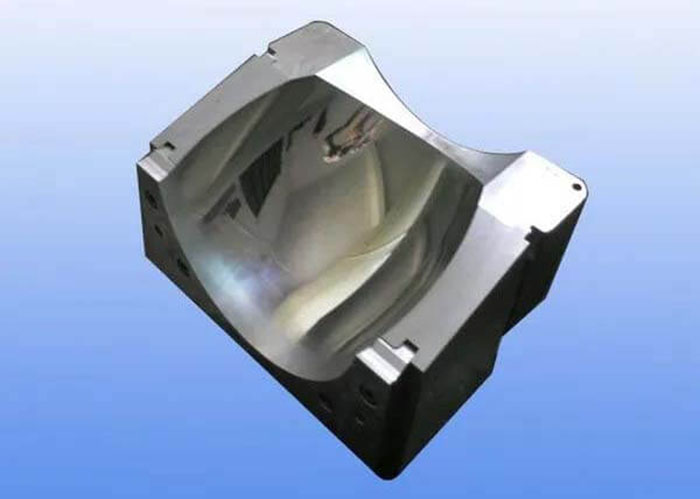

What are the 7 Plastic Injection Mold Polishing Techniques?

What is plastic injection mold polishing? Plastic injection mold polishing is a technique that helps to obtain smooth mold surfaces. It does this by removing the convex parts of the mold through plastic deformation and cutting. Generally, mold polishing techniques use wool wheels, whetstone strips, and sandpaper for manual polishing. Nowadays, in the process of […]