Description

What is an Injection Molding Machine Nozzle Tips?

The injection molding machine nozzle tips are a critical component that connects the plasticizing screw and barrel to the mold runner in the injection molding industry.

What is injection molding machine nozzle tip material?

The injection molding machine nozzle tip material is #45 steel material.

What are the functions of the injection molding machine nozzle tip?

The injection molding machine nozzle tips have a variety of functions:

1. During the pre-molding process, generate back pressure in the screw head to prevent the melt from the nozzle outflow.

2. During the injection process, generating injection pressure, shear effect, and accelerating animation conversion to improve the melt temperature homogenization effect.

3. During the holding pressure process, the role of insulation and shrinkage.

DGMF Mold Clamps Co., Ltd provides a hopper dryer for injection molding machines and hopper dryer nozzle bodies and tips of many different sizes and different types of injection molding nozzle tips. Contact us for more injection molding machine nozzle bodies and tips details.

Or other spare parts/accessories of the hopper dryer such as Hopper Dryer Heater, Hopper Dryer Screen Separator, Hopper Dryer Hose, Hopper Dryer Material Storage Tank, Hopper Dryer Material Suction Box, Hopper Dryer Blowers, Hopper Dryer Aluminum Cone, Hopper Dryer Dust Collector, Hopper Dryer Stands, Magnet Base for Hopper Dryer, Incline Stand Tilt Base, etc.

Advantages of Injection Molding Machine Nozzle Tips

Thickened nitrided steel

Not easy to deform, more wear-resistant, and durable

Round holes for bolts

Simple and easy, even distribution

Precision craftsmanship

No leakage, no shedding

Preferred material

Anti-corrosion and wear-resistant

The Injection Molding Machine Nozzle Bodies and Tips are supplied by DGMF Mold Clamps Co., Ltd, the mold clamps Manufacturer in China that also provides injection mold components, die press components, machine tools, and fasteners for your best choice.

Injection molding machine nozzle,

Nitriding and hardening split nozzle head,

Non-removable anti-clogging nozzle,

Nozzle injection molding,

Injection molding machine parts

Features of Injection Molding Machine Nozzle Tips

R head

High-precision spherical R head

Precise alignment sealing

Special process to harden the head

Durable

Heating circle position

Standardized heater diameter

Robust and reliable

Good thermal conductivity

Smooth gluing effect

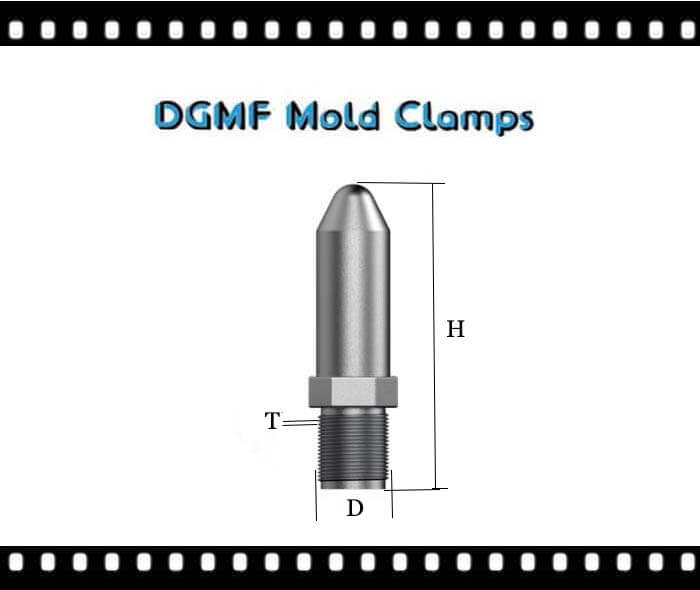

The Injection Molding Machine Nozzle Tips Specifications

Injection Molding Machine Nozzle Model: DGMF-Mold-Clamps-NT

Nitriding Hardened Injection Molding Machine Nozzle Size | ||||

| SKU | Model | Diameter(MM) | Thread(MM) | Length(MM) |

| DGMF-Mold-Clamps-NT-24-100 | M24*2/3*100 | 24 | 2 OR 3 | 100 |

| DGMF-Mold-Clamps-NT-24-130 | M24*2/3*130 | 24 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-27-85 | M27*2/3*85 | 27 | 2 OR 3 | 85 |

| DGMF-Mold-Clamps-NT-27-100 | M27*2/3*100 | 27 | 2 OR 3 | 100 |

| DGMF-Mold-Clamps-NT-27-110 | M27*2/3*110 | 27 | 2 OR 3 | 110 |

| DGMF-Mold-Clamps-NT-27-120 | M27*2/3*120 | 27 | 2 OR 3 | 120 |

| DGMF-Mold-Clamps-NT-27-130 | M27*2/3*130 | 27 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-27-150 | M27*2/3*150 | 27 | 2 OR 3 | 150 |

| DGMF-Mold-Clamps-NT-27-160 | M27*2/3*160 | 27 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-27-200 | M27*2/3*200 | 27 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-30-85 | M30*2/3*85 | 30 | 2 OR 3 | 85 |

| DGMF-Mold-Clamps-NT-30-100 | M30*2/3*100 | 30 | 2 OR 3 | 100 |

| DGMF-Mold-Clamps-NT-30-110 | M30*2/3*110 | 30 | 2 OR 3 | 110 |

| DGMF-Mold-Clamps-NT-30-120 | M30*2/3*120 | 30 | 2 OR 3 | 120 |

| DGMF-Mold-Clamps-NT-30-130 | M30*2/3*130 | 30 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-30-150 | M30*2/3*150 | 30 | 2 OR 3 | 150 |

| DGMF-Mold-Clamps-NT-30-160 | M30*2/3*160 | 30 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-30-160 | M30*2/3*180 | 30 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-30-200 | M30*2/3*200 | 30 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-33-90 | M33*2/3*90 | 33 | 2 OR 3 | 90 |

| DGMF-Mold-Clamps-NT-33-110 | M33*2/3*110 | 33 | 2 OR 3 | 110 |

| DGMF-Mold-Clamps-NT-33-130 | M33*2/3*130 | 33 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-33-160 | M33*2/3*160 | 33 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-33-180 | M33*2/3*180 | 33 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-33-200 | M33*2/3*200 | 33 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-33-250 | M33*2/3*250 | 33 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-33-280 | M33*2/3*280 | 33 | 2 OR 3 | 280 |

| DGMF-Mold-Clamps-NT-33-300 | M33*2/3*300 | 33 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-36-100 | M36*2/3*100 | 36 | 2 OR 3 | 100 |

| DGMF-Mold-Clamps-NT-36-120 | M36*2/3*120 | 36 | 2 OR 3 | 120 |

| DGMF-Mold-Clamps-NT-36-130 | M36*2/3*130 | 36 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-36-150 | M36*2/3*150 | 36 | 2 OR 3 | 150 |

| DGMF-Mold-Clamps-NT-36-160 | M36*2/3*160 | 36 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-36-180 | M36*2/3*180 | 36 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-36-200 | M36*2/3*200 | 36 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-36-230 | M36*2/3*230 | 36 | 2 OR 3 | 230 |

| DGMF-Mold-Clamps-NT-36-250 | M36*2/3*250 | 36 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-36-280 | M36*2/3*280 | 36 | 2 OR 3 | 280 |

| DGMF-Mold-Clamps-NT-36-300 | M36*2/3*300 | 36 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-36-350 | M36*2/3*350 | 36 | 2 OR 3 | 350 |

| DGMF-Mold-Clamps-NT-39-100 | M39*2/3*100 | 39 | 2 OR 3 | 100 |

| DGMF-Mold-Clamps-NT-39-120 | M39*2/3*120 | 39 | 2 OR 3 | 120 |

| DGMF-Mold-Clamps-NT-39-130 | M39*2/3*130 | 39 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-39-150 | M39*2/3*150 | 39 | 2 OR 3 | 150 |

| DGMF-Mold-Clamps-NT-39-160 | M39*2/3*160 | 39 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-39-180 | M39*2/3*180 | 39 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-39-200 | M39*2/3*200 | 39 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-39-230 | M39*2/3*230 | 39 | 2 OR 3 | 230 |

| DGMF-Mold-Clamps-NT-39-250 | M39*2/3*250 | 39 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-39-300 | M39*2/3*300 | 39 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-39-350 | M39*2/3*350 | 39 | 2 OR 3 | 350 |

| DGMF-Mold-Clamps-NT-42-110 | M42*2/3*110 | 42 | 2 OR 3 | 110 |

| DGMF-Mold-Clamps-NT-42-130 | M42*2/3*130 | 42 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-42-160 | M42*2/3*160 | 42 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-42-180 | M42*2/3*180 | 42 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-42-200 | M42*2/3*200 | 42 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-42-230 | M42*2/3*230 | 42 | 2 OR 3 | 230 |

| DGMF-Mold-Clamps-NT-42-250 | M42*2/3*250 | 42 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-42-300 | M42*2/3*300 | 42 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-42-350 | M42*2/3*350 | 42 | 2 OR 3 | 350 |

| DGMF-Mold-Clamps-NT-45-110 | M45*2/3*110 | 45 | 2 OR 3 | 110 |

| DGMF-Mold-Clamps-NT-45-130 | M45*2/3*130 | 45 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-45-160 | M45*2/3*160 | 45 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-45-180 | M45*2/3*180 | 45 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-45-200 | M45*2/3*200 | 45 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-45-230 | M45*2/3*230 | 45 | 2 OR 3 | 230 |

| DGMF-Mold-Clamps-NT-45-250 | M45*2/3*250 | 45 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-45-300 | M45*2/3*300 | 45 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-45-350 | M45*2/3*350 | 45 | 2 OR 3 | 350 |

| DGMF-Mold-Clamps-NT-48-110 | M48*2/3*110 | 48 | 2 OR 3 | 110 |

| DGMF-Mold-Clamps-NT-48-130 | M48*2/3*130 | 48 | 2 OR 3 | 130 |

| DGMF-Mold-Clamps-NT-48-160 | M48*2/3*160 | 48 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-48-180 | M48*2/3*180 | 48 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-48-200 | M48*2/3*200 | 48 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-48-230 | M48*2/3*230 | 48 | 2 OR 3 | 230 |

| DGMF-Mold-Clamps-NT-48-250 | M48*2/3*250 | 48 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-48-300 | M48*2/3*300 | 48 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-48-350 | M48*2/3*350 | 48 | 2 OR 3 | 350 |

| DGMF-Mold-Clamps-NT-50-160 | M50*2/3*160 | 50 | 2 OR 3 | 160 |

| DGMF-Mold-Clamps-NT-50-180 | M50*2/3*180 | 50 | 2 OR 3 | 180 |

| DGMF-Mold-Clamps-NT-50-200 | M50*2/3*200 | 50 | 2 OR 3 | 200 |

| DGMF-Mold-Clamps-NT-50-230 | M50*2/3*230 | 50 | 2 OR 3 | 230 |

| DGMF-Mold-Clamps-NT-50-250 | M50*2/3*250 | 50 | 2 OR 3 | 250 |

| DGMF-Mold-Clamps-NT-50-300 | M50*2/3*300 | 50 | 2 OR 3 | 300 |

| DGMF-Mold-Clamps-NT-50-350 | M50*2/3*350 | 50 | 2 OR 3 | 350 |

| DGMF-Mold-Clamps-NT-60-160 | M60*2/3/4*160 | 60 | 2 OR 3 OR 4 | 160 |

| DGMF-Mold-Clamps-NT-60-180 | M60*2/3/4*180 | 60 | 2 OR 3 OR 4 | 180 |

| DGMF-Mold-Clamps-NT-60-200 | M60*2/3/4*200 | 60 | 2 OR 3 OR 4 | 200 |

| DGMF-Mold-Clamps-NT-60-230 | M60*2/3/4*230 | 60 | 2 OR 3 OR 4 | 230 |

| DGMF-Mold-Clamps-NT-60-250 | M60*2/3/4*250 | 60 | 2 OR 3 OR 4 | 250 |

| DGMF-Mold-Clamps-NT-60-300 | M60*2/3/4*300 | 60 | 2 OR 3 OR 4 | 300 |

| DGMF-Mold-Clamps-NT-60-350 | M60*2/3/4*350 | 60 | 2 OR 3 OR 4 | 350 |

Features of Nitriding Hardened Spring Nozzle Tips Injection Molding

Hardened spring-loaded nozzle tips with anti-leakage and anti-stretching.

Built-in spring-loaded spool structure, using injection pressure and spring force to achieve the opening and closing of the nozzle.

Well-developed design – easy to disassemble and clean

Spring-loaded nozzles are used for processing thermoplastic rubber, preventing leakage and pulling.

Spring force is used to open and close the spool.

When the glue is injected, the spring compresses and the spool opens to inject glue. When no glue is injected, the spring force pushes the spool to close the nozzle. In order to achieve the purpose of high temperature without material leakage.

Nitriding Hardened Spring Nozzle Tips in Injection Moulding Size(Especially for Nylon/PET) | |||

| SKU | Model | Diameter(MM) | Thread(MM) |

| DGMF-Mold-Clamps-NT-27-2/3 | M27*2/3 with filter | 27 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-30-2/3 | M30*2/3 with filter | 30 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-33-2/3 | M33*2/3 with filter | 33 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-36-2/3 | M36*2/3 with filter | 36 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-39-2/3 | M39*2/3 with filter | 39 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-40-2/3 | M40*12 with filter | 40 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-42-2/3 | M42*2/3 with filter | 42 | 2 OR 3 |

| DGMF-Mold-Clamps-NT-45-2/3 | M45*2/3 with filter | 45 | 2 OR 3 |

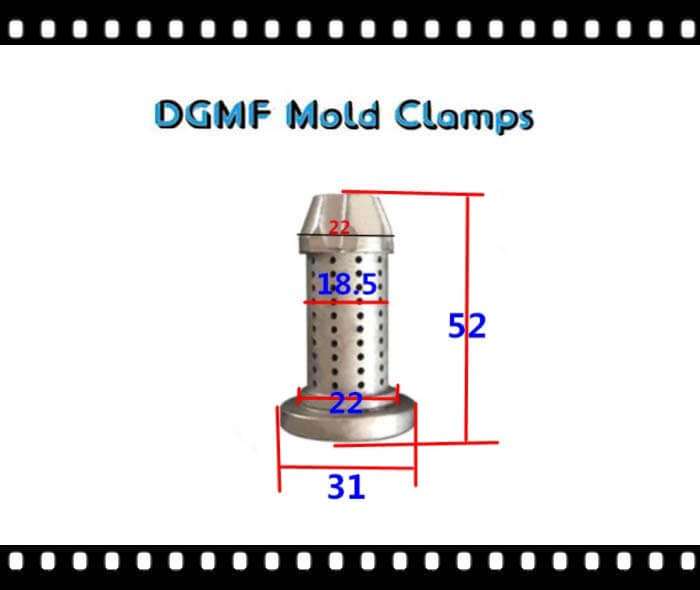

Nitriding and hardening nozzle tips with internal springs

Product Information

Name: Inner spring nozzle

Material: #45 high-quality steel

Precision: >0.05mm

Hardness: 40~50HRC

Characteristics of Nitriding and hardening nozzle tips with internal springs:

90% of hardened inner spring nozzle tips do not Leakage of glue, not pull, effectively improves the Higher product qualification rate, the overall hardening hardened, work efficiency greatly improved

Nitriding Hardened Spring Nozzle in Injection Moulding Size | |||

| SKU | Model | Diameter(MM) | Thread(MM) |

| DGMF-Mold-Clamps-NT-30-2 | M30*2 with filter | 30 | 2 |

| DGMF-Mold-Clamps-NT-30-3 | M30*3 with filter | 30 | 3 |

| DGMF-Mold-Clamps-NT-36-2 | M36*2 with filter | 36 | 2 |

| DGMF-Mold-Clamps-NT-36-3 | M36*3 with filter | 36 | 3 |

| DGMF-Mold-Clamps-NT-39-2 | M39*2 with filter | 39 | 2 |

| DGMF-Mold-Clamps-NT-39-3 | M39*3 with filter | 39 | 3 |

| DGMF-Mold-Clamps-NT-42-2 | M42*2 with filter | 42 | 2 |

| DGMF-Mold-Clamps-NT-42-3 | M42*3 with filter | 42 | 3 |

| DGMF-Mold-Clamps-NT-45-2 | M45*2 with filter | 45 | 2 |

| DGMF-Mold-Clamps-NT-45-3 | M45*3 with filter | 45 | 3 |

| DGMF-Mold-Clamps-NT-45-4 | M45*4 with filter | 45 | 4 |

Injection molding nozzle filter

Hardened Split Nozzle filter

Injection molding machine heat treatment nozzle filter

Extruder anti-clogging extension nozzle filter

Haitian blackened nozzle filter

Filter Nozzle for Injection Molding Size | |||

| SKU | Model | ID(MM) | Length(MM) |

| DGMF-Mold-Clamps-NT-12-35 | D12*H35MM | 12 | 35 |

| DGMF-Mold-Clamps-NT-14-35 | D14*H35MM | 14 | 35 |

| DGMF-Mold-Clamps-NT-16-35 | D16*H45MM | 16 | 45 |

| DGMF-Mold-Clamps-NT-18-50 | D18*H50MM | 18 | 50 |

| DGMF-Mold-Clamps-NT-20-50 | D20*H50MM | 20 | 50 |

| DGMF-Mold-Clamps-NT-22-50 | D22*H50MM | 22 | 50 |

| DGMF-Mold-Clamps-NT-25-49 | D25*H49MM | 25 | 49 |

DGMF Mold Clamps Co., Ltd Also provides the other nozzle tip components for your best choice. Contact us for more details.

What are the Applications of Injection Molding Machine Nozzle Tips?

How to align the injection molding machine nozzle tips?

1. When installing the mold, first of all, the injection nozzle and the chirp should be roughly centered, don’t press it tightly after closing the mold, use your hand to move the mold to make the R of the mold chirp and the injection nozzle automatically centered.

Check:

You can use a piece of kraft paper to pad on the chirp, move the shooting table so that the nozzle is against the chirp, and exit the shooting table to check the indentation of the kraft paper.”

2. When there is a serious offset of the shooting nozzle, you need to adjust the angle of the guide rail of the shooting table, different models have different settings of the guide rail, according to the actual go-to adjust.

Reviews

There are no reviews yet.