Description

What is a Knife Gate Valve?

A knife gate valve is also known as a knife gate, knife valve, knife slide gate valve, slurry valve, or mud valve, its opening and closing member is the gate, and the direction of movement of the gate is perpendicular to the direction of the fluid, by the knife blade gate can cut the fiber material to cut off the medium.

The gate has two sealing surfaces, the most commonly used mode gate valve two sealing surfaces to form a wedge, wedge angle varies with the parameters of the valve, usually 5 °, wedge-type knife gate valve gate can be made into a whole, called rigid gate;

The knife gate valve can also be made into a micro-deformation of the gate, in order to improve its craft, to make up for the angle of the sealing surface in the process of deviation, this gate is called the resilient gate.

The valve body does not actually exist in the chamber, the gate is lifted in the side guide groove and pressed against the seat by the bottom lug, if high media sealing is required, the O-seal seat can be used to achieve a two-way seal.

Knife gate valves have a smaller installation space, low working pressure, are less likely to accumulate debris, and are less expensive.

The knife gate valve is closed, the sealing surface can only rely on media pressure to seal, that is, rely on media pressure will be the sealing surface of the gate to the other side of the seat to ensure the sealing surface of the seal, which is self-sealing.

Most of the gate valves are forced to seal, that is, when the valve is closed, rely on external force to force the gate to the seat, to ensure the sealing surface of the seal. This type of valve in the pipeline should generally be installed vertically.

A knife gate valve is a slide gate valve device used in the fields of coal selection, gangue discharge, slag discharge, and urban sewage treatment in mining and power plants. The knife gate valves have a manual type, pneumatic type, and motorized/electric type for choosable.

The knife gate valves are used for a wide range of applications such as pulp and paper, chemical, petrochemical, power, mining, wastewater, and more.

They are used as isolation/on-off valves in the toughest corrosive, abrasive liquid, slurry, or dry material applications.

What are the driving methods of knife gate valves?

Knife gate valve drive mode: manual, sprocket, electric, pneumatic, hydraulic, bevel gear, electric control, and pneumatic-hydraulic drive mode.

What are the shapes of knife gate valves?

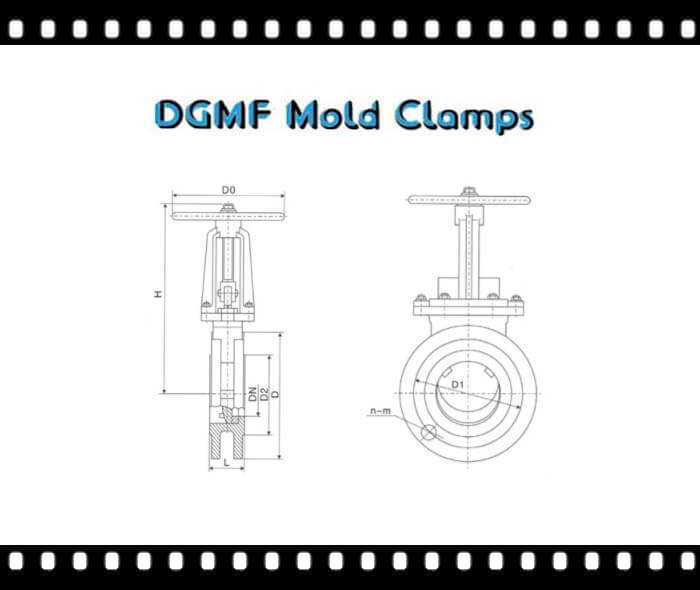

Knife-type gate valve shape has two kinds of open stem and concealed stem.

What are the materials of knife gate valves?

Knife gate valve materials are cast iron, cast steel, carbon steel, stainless steel, fluorine lining, etc.

What are the sealing methods of knife gate valves?

Knife gate valve sealing methods are hard-to-seal, soft seal, single-sided seal, double-sided seal, and other materials sealing.

Ultra-thin knife gate valve with its small size, small flow resistance, lightweight, easy to install, easy to disassemble, and other advantages completely solve the common gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve, other types of valves with large flow resistance, weight, difficult to install, covers an area of large and other difficult problems.

After the emergence of knife gate valves, a large number of general cut-off class valves and regulating valves have been replaced by the.

Advantages of knife gate valves

The knife gate valve with its small volume, small flow resistance, lightweight, easy to install, easy to disassemble, and other advantages completely solves the common gate valve, flat gate valve, ball valve, globe valve, regulating valve, butterfly valve, and other types of valve flow resistance, weight, difficult to install, covers an area of large and other difficult problems.

1. The series of knife gate valve products are made of high-quality stainless steel and carbon alloy material, with strong corrosion resistance;

2. The fully enclosed structure makes the internal parts free from media erosion;

3. Large diameter design can ensure that the internal parts will not be damaged by fluid erosion;

4. Light weight and small volume;

5. Easy installation and maintenance;

6. Can be customized according to customer requirements of various special sizes

7. The design of multi-turn closing makes the slide gate valve have a good self-closing ability;

8. The knife gate valve opening and closing torque are small.

9. Compact structure, reasonable design

10. Stainless steel and carbon alloy material, long service life

11. Manual, electric, motorized, and other driving methods

12. Factory direct sales, quality assurance

This series of knife gate products are mainly applied to the raw water treatment device of drinking water treatment plants and also can be widely used in the food and beverage industry water treatment and petrochemical enterprise’s production process of condensate fine treatment equipment supporting the use.

Performance of knife gate valves

1. Valve control can be done locally and remotely, and also remote position display and remote centralized control can be realized according to the user’s requirements.

2. Lightweight: the body is made of carbon steel, and the weight is reduced by about 20%-30% compared with the traditional gate valve, easy to install and maintain.

3. The use of this valve can improve the closing sealing performance of the conveying pipeline system and eliminate leakage to the maximum extent, which will play a positive role in promoting production efficiency and protecting the environment.

4. The sealing surface is made of highly wear-resistant, corrosion-resistant ceramic material, using inlay technology, with high corrosion resistance and good wear resistance, thus making the valve have a long service life, and the cost-performance ratio is 10 times higher than ordinary valves.

Knife gate valve caliber

Knife gate valves are made in two forms, concealed stem, and open stem, according to different calibers.

Knife gate valves can be made into V-shaped, triangular, and pentagonal channels internally. The V-shaped gate can be used as an adjustment control.

The motorized slide gate valves are supplied by DGMF Mold Clamps Co., Ltd, the mold clamps Manufacturer in China that also provides injection mold components, die press components, machine tools, and fasteners for your best choice.

Besides the Knife Gate Valves, DGMF Mold Clamps Co., Ltd also provides Hopper Slide Valves Gates, Motorized Slide Gate Valves, Pneumatic Slide Gate Valves, and Manual Slide Gate Valves for your devices.

Manual/electric/hydraulic/motorized/pneumatic slide valves

Drainage type/gate water type/gate air type/unloading type

Features of knife gate valves

The knife gate valve has small fluid resistance, and the sealing surface is subjected to small scouring and erosion of the medium.

Open and close with less effort, the media flow direction is not restricted, no disturbance, and no pressure reduction. Simple shape, short structure length, good manufacturing process, and a wide range of applications.

Lifted gate sealing surface scrapes adhesion from the sealing surface and automatically cleans up debris.

Stainless steel gate plates can prevent sealing leakage caused by corrosion.

A hard full gold sealing surface can ensure sealing wear resistance performance and requirements.

No groove on the sealing surface of the valve body, which does not produce accumulation of retention and can ensure flexible opening.

Short structure length, can save raw materials, and installation space also effectively supports the strength of the pipeline.

The scientific design of the upper sealing stuffing box makes the upper seal safe and effective and durable.

A triangular-shaped bracket saves raw materials and ensures the required mechanical properties.

The guide block on the valve body enables the correct movement of the gate, and the four squeeze blocks ensure the effective sealing of the gate.

The valve body reinforcement rib design improves the strength of the valve body.

The stainless steel stem is durable and the double-headed bolt makes opening and closing more rapid.

The driving mechanism can be chosen at will.

Above 150 calibers, with a fully enclosed structure, more effective opening and leakage prevention.

Fluorine rubber sealing surface can achieve a sealing effect and improve the use of temperature.

The rubber sealing surface is directly vulcanized in the valve body and will not fall off.

What are the transmission methods of knife gate valves?

A, the manual knife gate valve transmission mode

The transmission mode of the hand wheel knife gate valve

Manual knife gate valve transmission mode

B, worm gear drive knife gate valve

Spur gear drive knife gate valve

Bevel gear drive knife gate valve

Pneumatic knife gate valve

Electric knife gate valve

Liquid-operated knife gate valve, etc.

What are the control methods of knife gate valves?

Manual control knife gate valves.

Pneumatic control knife gate valves.

Solenoid-controlled knife gate valves.

Analogue remote computer-controlled knife gate valves.

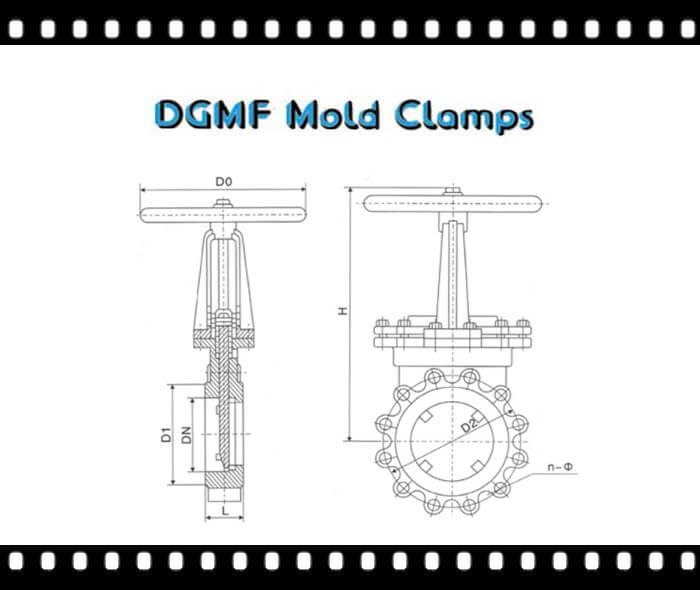

The Carbon & Stainless Steel Knife Gate Valves Specifications

Knife Slide Gate Valve Model: DGMF-Mold-Clamps-SV108

| Model | Specification | DN | D1 | D2 | D3 | N-M | z-d | L | Φ |

| DGMF-Mold-Clamps-SV108-50 | 2 Inch Slide Gate Valve | 50 | 160 | 125 | 100 | 2-M16 | 2-Φ19 | 48 | 2-2 |

| DGMF-Mold-Clamps-SV108-65 | 2.5 Inch Slide Gate Valve | 65 | 180 | 145 | 120 | 2-M16 | 2-Φ19 | 48 | 2-2 |

| DGMF-Mold-Clamps-SV108-80 | 3 Inch Slide Gate Valve | 80 | 195 | 160 | 135 | 2-M16 | 6-Φ19 | 51 | 2-6 |

| DGMF-Mold-Clamps-SV108-100 | 4 Inch Slide Gate Valve | 100 | 215 | 180 | 155 | 2-M16 | 6-Φ19 | 51 | 2-6 |

| DGMF-Mold-Clamps-SV108-125 | 5 Inch Slide Gate Valve | 125 | 245 | 210 | 185 | 2-M16 | 6-Φ19 | 57 | 2-6 |

| DGMF-Mold-Clamps-SV108-150 | 6 Inch Slide Gate Valve | 150 | 280 | 240 | 210 | 2-M20 | 6-Φ23 | 57 | 2-6 |

| DGMF-Mold-Clamps-SV108-200 | 8 Inch Slide Gate Valve | 200 | 335 | 295 | 265 | 2-M20 | 6-Φ23 | 70 | 2-6 |

| DGMF-Mold-Clamps-SV108-250 | 10 Inch Slide Gate Valve | 250 | 390 | 350 | 320 | 4-M20 | 8-Φ23 | 70 | 4-8 |

| DGMF-Mold-Clamps-SV108-300 | 12 Inch Slide Gate Valve | 300 | 440 | 400 | 368 | 4-M20 | 8-Φ23 | 76 | 4-8 |

| DGMF-Mold-Clamps-SV108-350 | 14 Inch Slide Gate Valve | 350 | 500 | 460 | 428 | 6-M20 | 10-Φ23 | 76 | 6-10 |

| DGMF-Mold-Clamps-SV108-400 | 16 Inch Slide Gate Valve | 400 | 565 | 515 | 482 | 6-M20 | 10-Φ23 | 89 | 6-10 |

| Knife Gate Valves Dimensional Specifications | ||||||||

| Model | MPa | DN | L | D1 | D2 | H | n-m | D0 |

| DGMF-Mold-Clamps-SV108 | 1.0 | 50 | 50 | 100 | 125 | 285 | 4-M16 | 180 |

| 65 | 50 | 120 | 145 | 298 | 4-M16 | 180 | ||

| 80 | 50 | 135 | 160 | 315 | 4-M16 | 220 | ||

| 100 | 50 | 155 | 180 | 365 | 8-M16 | 220 | ||

| 125 | 50 | 185 | 210 | 400 | 8-M16 | 230 | ||

| 150 | 60 | 210 | 240 | 475 | 8-M20 | 280 | ||

| 200 | 60 | 265 | 295 | 540 | 8-M20 | 360 | ||

| 250 | 70 | 320 | 350 | 630 | 12-M20 | 360 | ||

| 300 | 80 | 368 | 400 | 780 | 12-M20 | 400 | ||

| 350 | 90 | 428 | 460 | 885 | 16-M20 | 400 | ||

| 400 | 100 | 482 | 515 | 990 | 16-M22 | 400 | ||

| 450 | 100 | 532 | 565 | 1100 | 20-M22 | 530 | ||

| 500 | 110 | 585 | 620 | 1200 | 20-M22 | 530 | ||

| 600 | 130 | 685 | 725 | 1450 | 20-M27 | 600 | ||

| 700 | 160 | 800 | 840 | 1700 | 24-M27 | 600 | ||

| 800 | 160 | 898 | 950 | 2000 | 24-M30 | 680 | ||

| 900 | 190 | 898 | 1050 | 2300 | 28-M30 | 680 | ||

| 1000 | 180 | 1110 | 1160 | 2500 | 28-M30 | 700 | ||

| 1200 | 200 | 1325 | 1380 | 2800 | 32-M36 | 800 | ||

| DGMF-Mold-Clamps-SV108 | 1.6 | 50 | 50 | 100 | 125 | 285 | 4-M16 | 180 |

| 65 | 50 | 120 | 145 | 295 | 4-M16 | 180 | ||

| 80 | 50 | 135 | 160 | 315 | 8-M16 | 220 | ||

| 100 | 50 | 155 | 180 | 365 | 8-M16 | 220 | ||

| 125 | 50 | 185 | 210 | 400 | 8-M16 | 230 | ||

| 150 | 60 | 210 | 240 | 475 | 8-M20 | 280 | ||

| 200 | 60 | 265 | 295 | 540 | 12-M20 | 360 | ||

| 250 | 70 | 320 | 355 | 630 | 12-M22 | 360 | ||

| 300 | 80 | 368 | 410 | 780 | 12-M22 | 400 | ||

| 350 | 90 | 428 | 470 | 885 | 16-M22 | 400 | ||

| 400 | 100 | 482 | 525 | 990 | 16-M27 | 400 | ||

| 450 | 100 | 532 | 585 | 1100 | 20-M27 | 530 | ||

| 500 | 110 | 585 | 650 | 1200 | 20-M30 | 530 | ||

| 600 | 130 | 685 | 770 | 1450 | 20-M36 | 600 | ||

| 700 | 160 | 800 | 840 | 1700 | 24-M36 | 600 | ||

| 800 | 160 | 898 | 950 | 2000 | 24-M36 | 680 | ||

| 900 | 190 | 898 | 1050 | 2300 | 28-M36 | 680 | ||

| 1000 | 180 | 1110 | 1170 | 2500 | 28-M42 | 700 | ||

| 1200 | 200 | 1325 | 1390 | 2800 | 32-M48 | 800 | ||

What are the applications of a knife gate valve?

Knife gate valve use range from the general field extended to a broader range of industries, from the general industrial pipeline development to food, health, medicine, and other professional pipeline systems.

Knife gate valves are used in the following areas.

1. Mining, washing coal, steel industry – for washing coal pipeline, filter slurry pipeline, etc., ash discharge pipeline;

2. Purification devices – for wastewater, slurry, dirt, and clarified water with suspended matter;

3. paper industry – for any concentration of pulp, material-water mixture;

4. Power station ash removal – for ash slurry.

How to install the knife gate valve?

1. knife gate valve before installation shall check the valve cavity and sealing surface and other parts, do not allow dirt or sand adherence;

2. the bolts of each connection part, require uniform tightening;

3. check the packing parts required to press tight, both to ensure the sealing of the packing, but also to ensure that the gate open flexible;

4. the user in the installation of the valve before, must proofread the valve model, and connection size, and attention to the media flow direction, to ensure consistency with the valve requirements;

5. the user in the installation of the valve, must be reserved the necessary space for the valve drive;

6. the wiring of the driving device must be carried out in accordance with the wiring diagram;

7. the knife gate valve must be regularly maintained and must not be collided with and squeezed at will to avoid affecting the seal.

How to maintain the knife gate valve?

1. Handwheel, handle, and drive mechanism are not allowed to be used for lifting, and collision is strictly prohibited.

2. Double gate valve should be installed vertically (i.e. stem in vertical position, handwheel at the top).

3. Gate valve with a bypass valve should be opened before opening the bypass valve (to balance the pressure difference between the import and export and reduce the opening force).

4. Gate valves with transmission mechanisms should be installed according to the product instruction manual.

5. If the valve is frequently opened and closed, it should be lubricated at least once a month.

Knife gate valve execution standards

The pressure-temperature class of the shell material is according to the regulations of GB9131.

The structure length and limit deviation of the valve body according to the provisions of GB/T 15188.2

Flange connection size and sealing surface type with special requirements are specified in the order.

Stem and stem nut using trapezoidal thread, its basic dimensions and tolerances according to GB 5796.1 ~ 5796.4 provisions.

The size of the connection between the bracket and the drive unit is according to GB 12222.

The valve body is made of WCB according to GB 12229.

The gate plate is made of austenitic stainless steel (SS304), according to GB 12220, and GB4237.

The valve stem is made of 1Cr13, and 2Cr13 according to GB12220.

The bracket and packing gland are made of carbon steel (WCB), according to GB 12229.

The stem nut is made of copper alloy (ZCuZn38Mn2Pb2, ZCuSn5Pb5Zn5), according to GB 12225.

The upper seal (packing) is made of graphite asbestos rope.

Shell test and seal test according to the provisions of GB/T 13927.

For the effective sealing performance requirements, the leakage of the sealing test is calculated according to 1×mm/s.

Gas gate valve cleaning requirements according to the provisions of JB/T 7748.

The color of the paint is according to JB 106.

The packaging, storage, transportation, and quality assurance of the gas gate valve are according to the provisions of JB/T 7928.

Shell pressure: 1.5MPa, sealing pressure: 1.1 pressure, applicable temperature: 425℃, applicable medium: sewage, gas, pulp, etc.

Reviews

There are no reviews yet.