Description

What is a Cooling Joint Plug?

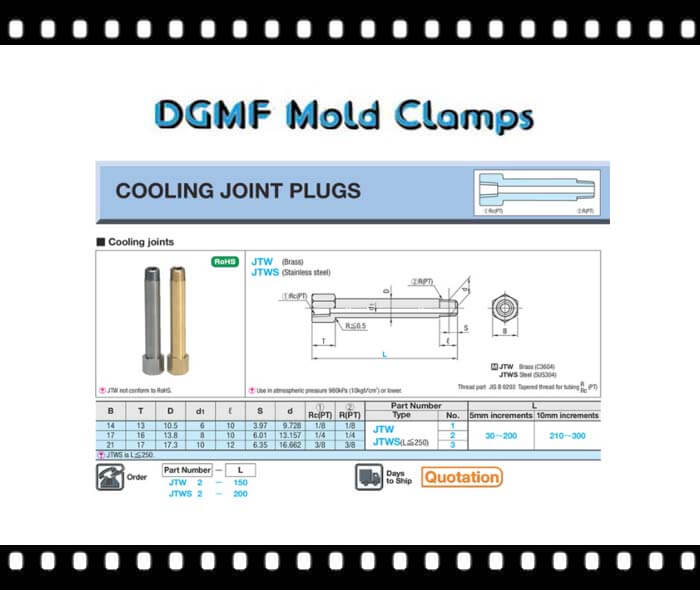

The cooling joint plug is a plug joint for cooling water. Cooling Joint Plugs (Material: Brass/Stainless Steel/Copper) are used for industrial applications, especially for injection molding industrial.

The main features of Cooling Joint Plugs HX-JTW, JTWS, JTW1/2/3-50/75/100/125/150/175/200/250/300

Safe and stable;

Made of high-quality brass/copper and stainless steel material;

Easy to operate;

It can be disassembled with an adjustable wrench and hex wrench;

Good sealing;

The internal and external threads at both ends adopt sealing tapered pipe threads;

The product size is complete;

Wide choice;

Etc.

The Cooling Joint Plugs HX-JTW, JTWS, JTW1/2/3-50/75/100/125/150/175/200/250/300 are supplied by DGMF Mold Clamps Co., Ltd. The mold clamps Manufacturer in China also provides injection mold components, die press components, machine tools, and fasteners for your best choice.

Cooling Joint Plugs JTWS JTW HX-JTW Specifications

| Specifications | B | T | D | D1 | L(mm) | L1(mm) | Rc(PT) | R(PT) | Material |

| DGMF-Mold-Clamps-JTW1-50 | 14 | 13 | 10.5 | 6 | 50 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-75 | 14 | 13 | 10.5 | 6 | 75 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-100 | 14 | 13 | 10.5 | 6 | 100 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-125 | 14 | 13 | 10.5 | 6 | 125 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-150 | 14 | 13 | 10.5 | 6 | 150 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-175 | 14 | 13 | 10.5 | 6 | 175 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-200 | 14 | 13 | 10.5 | 6 | 200 | 10 | 1/8 | 1/8 | Brass |

| DGMF-Mold-Clamps-JTW1-250 | 14 | 13 | 10.5 | 8 | 250 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-50 | 17 | 16 | 13.8 | 8 | 50 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-75 | 17 | 16 | 13.8 | 8 | 75 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-100 | 17 | 16 | 13.8 | 8 | 100 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-125 | 17 | 16 | 13.8 | 8 | 125 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-150 | 17 | 16 | 13.8 | 8 | 150 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-175 | 17 | 16 | 13.8 | 8 | 175 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-200 | 17 | 16 | 13.8 | 8 | 200 | 10 | 1/4 | 1/4 | Brass |

| DGMF-Mold-Clamps-JTW2-250 | 17 | 17 | 13.8 | 10 | 250 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-50 | 21 | 17 | 17.3 | 10 | 50 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-75 | 21 | 17 | 17.3 | 10 | 75 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-100 | 21 | 17 | 17.3 | 10 | 100 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-125 | 21 | 17 | 17.3 | 10 | 125 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-150 | 21 | 17 | 17.3 | 10 | 150 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-175 | 21 | 17 | 17.3 | 10 | 175 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-200 | 21 | 17 | 17.3 | 10 | 200 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTW3-250 | 21 | 17 | 17.3 | 10 | 200 | 12 | 3/8 | 3/8 | Brass |

| DGMF-Mold-Clamps-JTWS1-50 | 14 | 13 | 10.5 | 6 | 50 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-75 | 14 | 13 | 10.5 | 6 | 75 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-100 | 14 | 13 | 10.5 | 6 | 100 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-125 | 14 | 13 | 10.5 | 6 | 125 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-150 | 14 | 13 | 10.5 | 6 | 150 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-175 | 14 | 13 | 10.5 | 6 | 175 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-200 | 14 | 13 | 10.5 | 6 | 200 | 10 | 1/8 | 1/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1S-250 | 14 | 13 | 10.5 | 8 | 250 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-50 | 17 | 16 | 13.8 | 8 | 50 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-75 | 17 | 16 | 13.8 | 8 | 75 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-100 | 17 | 16 | 13.8 | 8 | 100 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-125 | 17 | 16 | 13.8 | 8 | 125 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-150 | 17 | 16 | 13.8 | 8 | 150 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-175 | 17 | 16 | 13.8 | 8 | 175 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-200 | 17 | 16 | 13.8 | 8 | 200 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-250 | 17 | 16 | 13.8 | 8 | 200 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS2-300 | 17 | 16 | 13.8 | 8 | 200 | 10 | 1/4 | 1/4 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-50 | 21 | 17 | 17.3 | 10 | 50 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-75 | 21 | 17 | 17.3 | 10 | 75 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-100 | 21 | 17 | 17.3 | 10 | 100 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-125 | 21 | 17 | 17.3 | 10 | 125 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-150 | 21 | 17 | 17.3 | 10 | 150 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-175 | 21 | 17 | 17.3 | 10 | 175 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTWS3-200 | 21 | 17 | 17.3 | 10 | 200 | 12 | 3/8 | 3/8 | Stainless Steel |

| DGMF-Mold-Clamps-JTW1-50 | 14 | 13 | 10.5 | 6 | 50 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-75 | 14 | 13 | 10.5 | 6 | 75 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-100 | 14 | 13 | 10.5 | 6 | 100 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-125 | 14 | 13 | 10.5 | 6 | 125 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-150 | 14 | 13 | 10.5 | 6 | 150 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-175 | 14 | 13 | 10.5 | 6 | 175 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-200 | 14 | 13 | 10.5 | 6 | 200 | 10 | 1/8 | 1/8 | Copper |

| DGMF-Mold-Clamps-JTW1-250 | 14 | 13 | 10.5 | 8 | 250 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-50 | 17 | 16 | 13.8 | 8 | 50 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-75 | 17 | 16 | 13.8 | 8 | 75 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-100 | 17 | 16 | 13.8 | 8 | 100 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-125 | 17 | 16 | 13.8 | 8 | 125 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-150 | 17 | 16 | 13.8 | 8 | 150 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-175 | 17 | 16 | 13.8 | 8 | 175 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-200 | 17 | 16 | 13.8 | 8 | 200 | 10 | 1/4 | 1/4 | Copper |

| DGMF-Mold-Clamps-JTW2-250 | 17 | 17 | 13.8 | 10 | 250 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-50 | 21 | 17 | 17.3 | 10 | 50 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-75 | 21 | 17 | 17.3 | 10 | 75 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-100 | 21 | 17 | 17.3 | 10 | 100 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-125 | 21 | 17 | 17.3 | 10 | 125 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-150 | 21 | 17 | 17.3 | 10 | 150 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-175 | 21 | 17 | 17.3 | 10 | 175 | 12 | 3/8 | 3/8 | Copper |

| DGMF-Mold-Clamps-JTW3-200 | 21 | 17 | 17.3 | 10 | 200 | 12 | 3/8 | 3/8 | Copper |

When using the Cooling Joint Plugs for molds:

The brass/Copper/Stainless Steel Cooling Joint Plug is a fitting joint for the plastic injection mold.

Choose pipe thread PT (1/8, 1/4, 3/8) and length L ( 50, 75, 100, 125, 150, 200, 250 ).

Cooling, cooling water, and hot water circuits. It is suitable for the cooling system of plastic molds, die-casting molds, blow molding molds, mold temperature controllers, injection molding machines, blow molding machines, die-casting machines, etc., and can be used for water, oil, and ventilation.

Precautions for the use of quick connectors for molds:

1. Do not use fluid other than the applicable fluid.

2. Do not exceed the maximum operating pressure limit when using.

3. Do not use it outside the operating temperature range to prevent wear or leakage of the sealing material.

4. Do not artificially hit, bend, stretch, and prevent damage.

5. Do not use in places where metal powder or sand dust is mixed to prevent shoddy work or leakage.

6. For threaded installation, do not exceed the maximum tightening torque during installation to prevent damage.

7. Do not use cracked hoses to prevent leakage or fall-off.

8. If it is used in a machine with vibration and impact, the durability will be reduced.

9. The fluid used must be clean fluid filtered through a filter.

10. Do not disassemble the quick connector.

Reviews

There are no reviews yet.