Description

What are the Top Locks For Molding Machines?

Top locks are the mold parting line components for injection molding machines. Top locks are machined on the centerline axis, both vertically and horizontally from the face of the mold.

Top locks should be machined at the same time as the leader pins and bushings to ensure parallelism and proper location relative to the leader pins. Unlike side locks, top locks are machined in two separate setups, requiring a high degree of machining precision.

DGMF Mold Clamps Co., Ltd supplies mold locks including many different styles for both top locks and side locks requirements. Contact DGMF for more mold lock details.

Parting Line Component Top Locks Features:

Top Locks For Molding Machines Characteristic description:

1. Effectively solve the problem of the side-mounted 0° positioning slot.

Especially for large mold embryos more convenient.

2. Used for plastic molds with high quality and dimensional accuracy requirements.

3. Material: SK3 equivalent to YK30 (HRC48°-56°)

Top Locks For Molding Machines Features:

Precision crafted

Excellent quality

Complete specifications

Stable performance

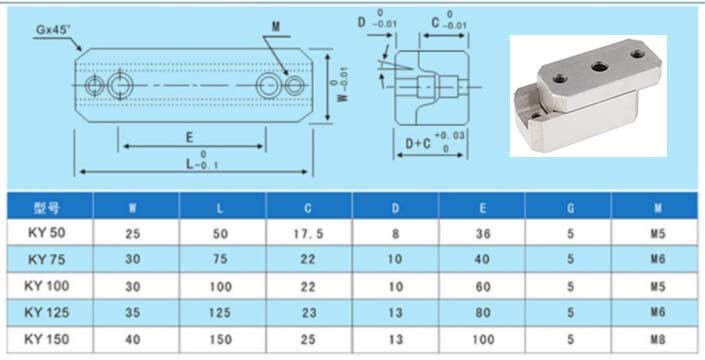

Model: DGMF-Mold-Clamps-053-KY

The new fixed block KY style top lock can absorb the expansion of the mold plate when the mold temperature is high such as hot firmware resin and ensure the correct positioning function.

Caution: Please keep about 1MM end face when using to prevent collision between the end face of the pin and the sleeve when closing the mold, which may cause damage.

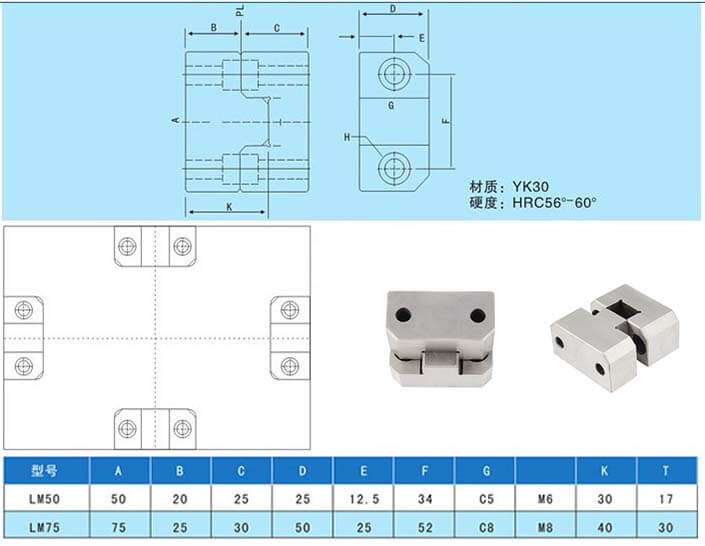

Model: DGMF-Mold-Clamps-053-LM

Material: 20CR/YK30

Hardness:50-54HRC

Applicable occasions: Applicable to plastic molds with particularly high requirements for plastic quality and size.

Integral positioning mold lock.

Generally applicable to large and medium-sized molds, deep cavity molds, and molds with large lateral force.

The general condition of the bevel requires an inlaying of the wear plate and the designing of an oil storage groove on the working surface.

The wear plate of the export mold requires sinker fixing.

Slope positioning mold lock.

Generally applicable to small and medium-sized molds, shallow cavity molds, and molds with less lateral force.

Purchase standard parts.

Zero-degree positioning mold locks the top locks.

Generally used in small molds.

When there is a friction surface less than 10 degrees in the mold parting surface, use the zero-degree positioning block top lock to protect the parting surface from friction. The oil reservoir is designed on both sides of the working surface of the guide.

DGMF Mold Clamps Co., Ltd supplies the ejector pins, straight ejector pins, ejector sleeve pins, ejector blades, shoulder ejector pins, guide pins, core pins, angle pins, dowel pins, guide bushing, A-type sprue bushing, B-type sprue bushing, C-type sprue bushing, small gate sprue bushing, big gate sprue bushing, support pillars, slide retainer, taper block set, round tapered interlocks, side lock, etc.

Contact the DGMF team for the injection mold components Top Locks For Molding Machines specification, inventory, and pricing.

Or other mold locks as the below showing.

DGMF Mold Clamps Co., Ltd is the mold clamps Manufacturer in China, also provides injection mold components, die press components, machine tools, and fasteners for your best choice. Contact us for more top lock details.

Reviews

There are no reviews yet.