What is the double-color injection molding process?

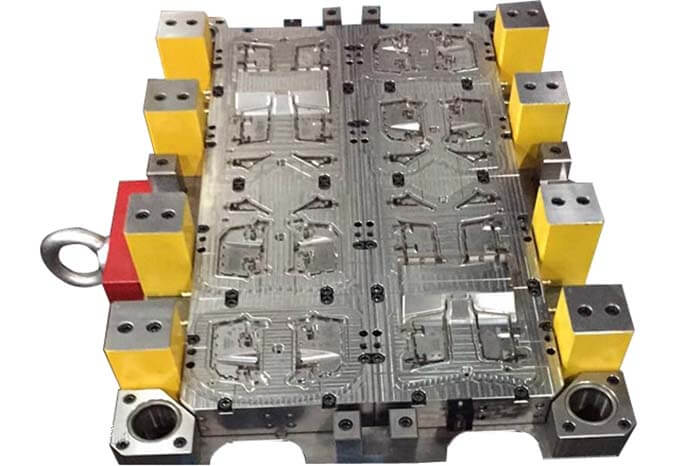

A double-color injection molding is a molding process in which two plastic materials are injected into the same injection molding machine and molded twice, but the product only comes out of the mold once.

Double-color injection molding process is also called two-color injection molding 2 color injection molding, is usually done by a set of molds and requires a special double-color injection machine.

Double-color injection molding is a process in which two different materials are injected into the same set of molds so that the molded parts are formed by two materials. Some of the two materials are different colors, some are different soft and hard, thus improving the aesthetics of the product and assembly and other properties.

double-color molds are becoming more and more popular in the market because this double-color injection molding process can make the appearance of the product more beautiful, and easy to change the color without painting, but the cost is expensive and the technical requirements are high.

What are the classifications of double-color molds?

Double-color molds use two different types of plastic, and the two plastics in the product can be clearly distinguished from plastic products called two-color products.

Double-color molds are installed on the same injection molding machine with two sets of injection devices (i.e. double-color injection molding machine), and the molds that inject two types of plastics in sequential order and produce two-color products are called two-color molds.

What are the types of Double-color injection molding machines?

There are usually two types of double-color injection molding machines, injection screw parallel type injection molding machine and injection screw vertical type injection molding machine.

Parallel type double-color injection molding machine

The injection screws are arranged in parallel and can act independently or simultaneously, with two sets of independently acting ejector mechanisms.

Vertical type double-color injection molding machine

The injection screw is arranged vertically in one plane, and can also act independently or simultaneously, but there is only one set of ejector mechanisms.

What are the Double-color mold types?

Double-color molds can be classified by structure: core rotating type, core retracting type, and pushing plate rotating type.

Among them, the core rotary type can be divided into split and one-piece types. The so-called split type uses two pairs of molds installed on one injection molding machine to complete the injection molding of two-color products.

The so-called split type is to use two molds on one injection molding machine to complete the injection molding of two-color products, while the one-piece type is to complete the injection molding of two-color products in one mold, of which the core rotation split type is more widely used.

What are the characteristics of double-color mold?

- The two shapes of the female mold are different, molding 1 kind of product respectively, while the two shapes of the male mold are exactly the same.

- The front and back die of the mold must match after rotating 180° with the center. This check action must be done when designing, and this point has high requirements for mold frame positioning processing.

- The total thickness of the front mold panel plus A plate must not be less than 170mm. Please check carefully the other reference data of this type of injection molding machine, such as the maximum mold thickness, minimum mold thickness, KO hole distance, etc.

- The water outlet of the three-panel mold should be designed to automatically release the mold. Particular attention should be paid to whether or not the release action of the soft rubber spout can be automatically released.

- In the design of the mother mold of the second injection, in order to avoid the insertion (or rubbing) of the second mother mold into the first molding of good products, you can design part of the avoidance of hollow. However, the strength of each sealing position must be carefully considered, i.e., whether there will be a deformation of the plastic under the large injection pressure in the injection molding, which may lead to the possibility of the second injection of the batch front.

- When injection molding, the size of the first injection molded product can be slightly larger so that it can be pressed tighter with another male mold in the second molding to achieve the role of sealing glue.

- Pay attention to whether the flow of plastic will move the first molded product during the second injection so that the glue position will be deformed. If there is this possibility, we must find ways to improve it.

- Before the A and B plates are combined, pay attention to whether the front mold slider or slant top will be reset first and crush the product? In this case, we must find a way to make the A and B plates close the mold first, and then the slider or slant top of the front mold can be reset.

- The water transportation arrangement of the two female and male dies should be sufficient, balanced, and the same.

- 99% of the time, the hard plastic part of the product is injected first, and then the soft plastic part of the product is injected. Because soft rubber is easy to deform.

What are the advantages of double-color injection molding?

Compared with traditional injection molding, the double-color injection molding process has the following advantages.

- The core material can use low viscosity material to reduce the injection pressure.

- For environmental reasons, the core material can be used as recycled secondary material.

- According to the different characteristics of use, such as the use of soft material for thick finished skin material, hard material for core material, or core material can be used to reduce the weight of foam plastic.

- Can use lower quality core material to reduce costs.

- Skin or core material can be used with expensive and special surface properties, such as anti-electromagnetic interference, high electrical conductivity, and other materials to increase product performance.

- Appropriate skin material and core material can reduce the residual stress of molded products, and increase the mechanical strength or product surface properties.

- Produce products such as marble patterns.

Development of double-color injection molding

From the characteristics and applications of multi-color injection molding and double-color injection molding, it can be seen that there is a trend to gradually replace the traditional injection molding process in the future.

The innovative double-color injection molding technology not only improves the precision of the injection molding process but also provides a high level of process technology and opens up the scope of the injection molding process. Innovative double-color injection molding equipment and processes are needed to meet the increasing demand for diverse, high-quality, and high-value-added products.

Double-color injection molding has been widely used in almost all plastic fields such as electronic products, power tools, medical products, home appliances, toys, etc. The production and molding of double-color molds, as well as the development of double-color multi-color injection molding machines and double-color injection molding materials, have also developed rapidly.

Besides the What is Double-Color Injection Molding article, you may also be interested in the below articles?

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept