What is the melt flow index?

Melt flow index (MFI), known as melt index, is a value that indicates the fluidity of plastic material during molding processing.

The melt flow index (MFI) is a measure of the ease of flow of the melt of a thermoplastic polymer. It is defined as the weight of the polymer in grams flowing in 10 min through a die of specific diameter and length by a pressure applied by a given weight at a given temperature.

It is developed by the American Society for Measurement Standards (ASTM) based on the usual method used by DuPont (USA) to identify the properties of plastics, and its test method is as follows

First let the plastic particles melt into plastic fluid, and then in a certain time (10 minutes), a certain temperature and pressure (various materials standard different), through a diameter of 2.1mm round tube after the flow of its grams (g) number.

The larger the value, the better the processing fluidity of the plastic material, and vice versa, the worse.

The so-called melt mass flow rate is the average weight of each section of the extruded specimen converted into 10 minutes of extrusion volume. The unit is (g/10min), expressed in MFR L

MFR=600 units

In the formula: MFR — melt mass flow rate, g/10min.

m – the average value of cutting multiple specimens, g.

t – time interval for cutting samples, s.

600 – reference time (10 min), s.

What is the melt flow rate?

Melt flow rate, formerly known as melt index, is defined as the amount of extruded thermoplastic material in a certain period of time under specified conditions, i.e., the mass of melt passing through the capillary tube of a standard die every 10 min, expressed as MFR, in g/10 min.

The melt flow rate can characterize the viscous flow characteristics of thermoplastic in the molten state, which is important for ensuring the quality of thermoplastic and its products, and for adjusting the production process.

In recent years, the melt flow rate has been extended from the concept of mass to the concept of volume, i.e., the melt volume flow rate has been added.

It is defined as the volume of melt per 10 min through the standard mouth mold capillary, expressed in MVR, the unit is cm/10 min.

From the volume point of view, it provides a scientific guiding parameter for characterizing the viscous flow properties of thermoplastics in the molten state, and for adjusting the production process.

For the original melt flow rate, it is explicitly referred to as the melt mass flow rate, which is still recorded as MFR.

The melt mass flow rate and melt volume flow rate have been clearly put forward in the recent ISO standard, and our standard will be revised accordingly, while in the import and export business, the determination of melt volume flow rate will also be applied soon.

How to test the melt flow index?

The most commonly used test standard for melt flow index is ASTM D 1238. The measuring instrument for this test standard is the Melt Indexer, unit: g/10 min.

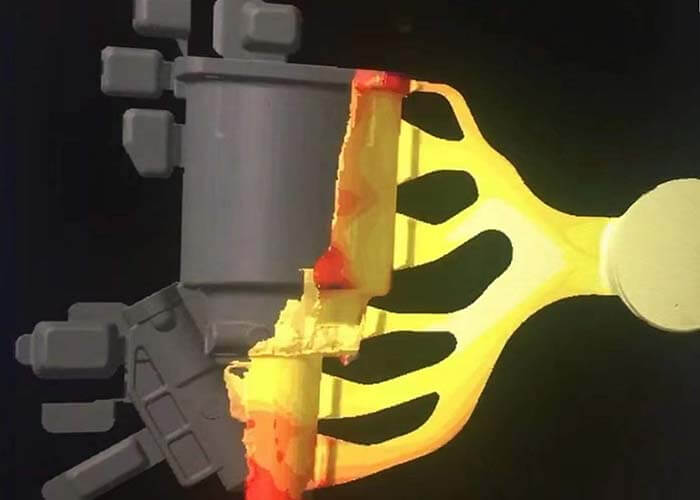

The melt flow index test procedure is: the polymer (plastic) material to be tested is placed in a small tank with a thin tube at the end of the tank, with a diameter of 2.095 mm and a length of 8 mm.

After heating to a certain temperature (often 190 degrees), the upper end of the raw material that is a certain weight applied by the piston downward pressure extrusion, measurement of the raw material in 10 minutes by the weight of the extrusion, that is, the flow index of the plastic.

Sometimes you will see this expression: MI 25g/10min, which means that the plastic is extruded 25g in 10 minutes. The MI of common plastics ranges from 1 to 25.

The higher the MI, the lower the viscosity and the lower the molecular weight of the plastic material;

The vice versa, the higher the viscosity and the higher the molecular weight of the plastic.

In addition to the melt mass flow rate (MFR), the melt volume flow rate (MVR) can also be used for measurement.

What is the approximate value of the viscosity function of the melt flow index?

The exact determination of the viscosity function by assay is very expensive, therefore, for most polymers only the melt flow index (MFI) is available as a guideline value to characterize the flow behavior, so an approximate method of finding the approximate viscosity function for a known melt flow index and softening temperature pair is briefly described.

This method is only useful for estimation and in any case, does not exclude the need for as accurate a rheological determination as possible for many polymers to be processed.

What is a melt flow index tester?

A melt flow index tester is a simple capillary type instrument that operates at low shear rates.

Although there are some differences between various models of domestic melt flow index tester, they all consist of two parts: the main body and the heating control system.

The heating control system can automatically control the temperature in the main barrel within the set temperature range, requiring the temperature fluctuation to be maintained within 0.8℃.

The heater of the barrel is composed of two groups of heating elements, one group of heating elements is used to supply 90% of the heat required to keep the barrel at a constant temperature, and the current supply is continuous.

The other group of heating elements is used to supply the heat required to maintain the barrel temperature within the fluctuating range of the fluctuating temperature. The mass load of the weights is applied to the molten polymer specimen in the barrel by means of a piston rod and presses the polymer melt out of the capillary tube.

A cutter is used at regular intervals to cut the molten polymer sample from the capillary tube. The melt flow index of the polymer can be obtained by weighing its mass.

Besides the What is the Melt Flow Index (MFI) article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept