What are the different types of mould?

There are many different types of moulds, which can be classified into various types according to different classification criteria. The following are some common 10 types of moulds.

Different Types of Mould 1: Stamping moulds

A stamping mould, including blanking moulds, bending moulds, stretching moulds, and so on, is used for stamping and forming metal sheets. This mould applies pressure to the metal plate through stamping equipment, causing it to undergo plastic deformation to obtain the required shape and size of the parts.

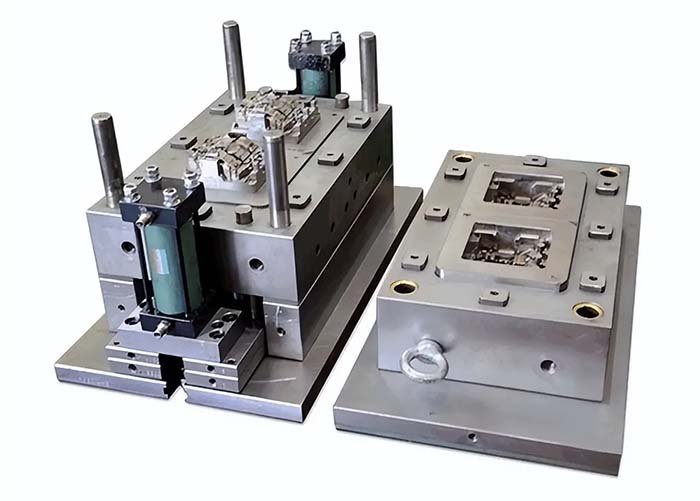

Different Types of Mould 2: Plastic mould

A plastic mould is used in the moulding process of plastic products, including injection moulds, blow moulds, compression moulds and so on. Plastic moulds through the injection machine and other equipment with the molten state of the plastic injected into the mould cavity, after cooling and curing demoulding, to get plastic products.

Different Types of Mould 3: Die-casting mould

The die-casting mould is specially used for the metal die-casting moulding process, especially suitable for processing low melting point alloy materials. Die casting mould in high temperature and high-pressure conditions, the molten metal is quickly injected into the mould cavity, and rapid cooling and solidification, the formation of precision metal parts.

Different Types of Mould 4: Forging forming mould

A forging forming mould is used for metal material forging processing, including die forging mould, free forging mould and so on. By applying pressure to the metal material, the forging mould makes it undergoes plastic deformation and fills up the mould cavity, so as to obtain the forging part of the required shape and size.

Different Types of Mould 5: Casting mould

Casting mould is used in metal casting process, including sand moulds, metal type moulds and so on. Casting moulds according to the product shape and structure requirements to make the cavity and sprue system, the molten metal is poured into the mould, after cooling and solidification to remove the mould, to get the casting.

Different Types of Mould 6: Powder metallurgy mould

Powder metallurgy mould is used for the moulding and processing of powder metallurgy materials, including pressing mould, sintering mould and so on. Powder metallurgy moulds are used to press metal powder into blanks of the required shape and size through the pressing moulding and sintering process, and then get the final products after subsequent processing.

Different Types of Mould 7: Rubber mould

A rubber mould is used for the moulding and processing of rubber products, including press moulds, extrusion moulds, injection moulds, and so on. Rubber moulds are designed and manufactured according to the characteristics of rubber materials and product requirements of the cavity and pouring system, the rubber material will be injected into the mould after vulcanization to obtain rubber products.

In addition, there are many other types of moulds such as ceramic moulds, glass product moulds, economic moulds (simple moulds), etc., which are suitable for the moulding and processing needs of different materials and products.

In practice, the type and structure of moulds will be selected and designed according to specific product requirements and production conditions.

Which types of moulds need to be polished?

Among these 10 different types of moulds, the following types of moulds usually require polishing.

First, injection mould

To obtain high quality plastic products, its cavity, and core surface often need to be polished, in order to achieve a mirror effect, to avoid the surface of the plastic parts defects.

Second, die-casting mould

The high-requirements for surface quality, cavity and core need to be polished to ensure the casting of dimensional accuracy and surface quality.

Third, stamping mould

Stamping moulds used to produce appearance parts, the surface of its working parts may need to be polished to meet the appearance requirements of the parts.

In summary, the mould is generally divided into stamping mould, plastic mould, die-casting mould, forging mould, rubber mould, powder metallurgy mould several.

The often need to be polished injection moulds, die-casting moulds, stamping moulds are the three kinds of moulds in the 10 different types of moulds.

Besides the 10 Different Types of Moulds article, you may also be interested in the below articles.

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

What Is The Difference Between Two-Platen Mold And Three-Platen Mold?