The T-slot bed plate, also called the T-slotted plate, is a kind of cast iron plate with a T-slotted surface used for assembly, debugging machinery, and equipment. Cast iron T-slotted bed plate table and scribing platform strictly implement the relevant national industry standards, using high-strength cast iron casting that is not only stable and accurate but durable.

A T-slot bed plate table is a kind of industrial gauge mainly used to fix the workpiece and is used by the clamp workers to debug the equipment, assembly equipment, maintenance equipment, and the basic work platform.

The role of the T-slot bed plate: fixed workpiece

Tools: industrial gauges

Specification:100*100-3000*6000

What is T-slot bed plate material?

The T-slot bed plate is made of high-strength cast iron HT200-300 with working surface hardness HB170-240, which is artificially treated twice (artificial annealing 600 degrees-700 degrees and natural aging 2-3 years), and the working surface of the T-slot platform adopts a scraping process.

T-slot bed plate working surface can be processed V-shaped, T-shaped, U-shaped groove and a round hole, long hole, etc., which can be used to fix power mechanical equipment. The accuracy of using this product is stable and the wear resistance is good.

T-slot bed plate working surface is processed with T-slot, mainly used to fix the workpiece, and is used by the clamp workers to debug the equipment, assembly equipment, maintenance equipment, and the basic work plane.

High strength cast iron HT200-300 working surface hardness of HB170-240 after two artificial treatments (artificial annealing 600 degrees – 700 degrees or natural aging 2-3 years) use the product precision stability, good wear resistance.

Some cast iron T-slot bed plate table working surfaces are scraping and researching processes, using the method of color coating for inspection to ensure the accuracy of the plane.

The T-slot bed plate is widely used in the assembly, debugging, welding, and riveting of mechanical power equipment. The surface of this product, with a T-slot table, can be fixed by mechanical equipment.

What are the T-slot bed plate specifications?

100*100-3000*6000 (also can be made into other specifications according to actual requirements)

| T-slot bed plate specifications | ||||

Specifications(LxW) | Accuracy grade | |||

0-grade | 1-grade | 2-grade | 3-grade | |

Flatness tolerance | ||||

200×200 | 5 | 10 | 20.5 | |

200×300 | 5.5 | 11 | 22 | |

300×300 | 5.5 | 11 | 22 | |

300×400 | 6 | 12 | 24 | |

400×400 | 6.5 | 12.5 | 25 | |

400×500 | 6.5 | 13 | 26 | 66 |

400×600 | 7 | 14 | 27.5 | 70 |

500×500 | 6.8 | 14 | 28 | 68 |

500×600 | 7 | 14.2 | 28.5 | 71 |

500×800 | 8 | 15.5 | 31 | 78 |

600×800 | 8 | 16 | 32 | 80 |

600×900 | 8.3 | 16.5 | 33 | 83 |

1000×750 | 9 | 18 | 36 | 90 |

1000×1000 | 20 | 40 | 97 | |

1000×1200 | 20.5 | 41 | 103 | |

1000×1500 | 22 | 45 | 112 | |

1000×2000 | 26 | 52 | 130 | |

1500×2000 | 28 | 56 | 140 | |

1500×3000 | 70 | 174 | ||

2000×3000 | 74 | 184 | ||

2000×4000 | 88 | 219 | ||

What is T-slot bed plate accuracy grade?

According to the national standard metrological verification regulations, respectively, 0, 1, 2, 3 four levels (the smaller the value the higher the precision)

What is T-slot bed plate Flatness level?

The flatness of the T-slot bed plate can be divided into the:

① AA level: its flatness (μm) = 1 + 1.6D2 (D is the diagonal length or diameter of the platform), used for highly precise determination, commonly used in the laboratory.

② Grade A: The flatness is twice the error of grade AA, commonly used in the tool inspection room for precision gauge inspection.

③ Grade B: its flatness is four times the error of the AA level, commonly used in tool inspection rooms or in the field to test gauges or scribing.

Flatness calculation formula

000 level: 1 × (1 + d / 1000) 1 level: 8 × (1 + d / 1000)

0 0 level: 2 × (1 + d / 1000) 2 level: 16 × (1 + d / 1000)

Grade 0: 4×(1+d/1000)Grade 3: 40×(1+d/1000)

What are the technical requirements of the T-slot bed plate?

- T-slot bed plate working surface shall not have defects such as sand holes, pores, cracks, shrinkage, scratches, bruises, rust spots, etc., that seriously affect the appearance and use.

- The surface of the T-slot bed plate should be cleared of type sand and smooth and painted firmly.

- The working surface of the T-slot bed plate with accuracy grade 0-3, the sand hole with a diameter less than 15mm, is allowed to be blocked with the same material, and its hardness should be less than the hardness of the surrounding material. The sand holes blocked on the working surface should be no more than 4, and the spacing between sand holes should be no less than 80mm.

- T-slot bed plate should be made of high-quality fine gray cast iron or alloy and other materials, and the hardness of its working surface should reach 170-220HB.

- T-slot bed plate working surface should usually adopt a scraping process. The maximum allowable value of the surface roughness Ra is 5um for the working surface of the T-slot platform with a scraping process of grade 3.

- Using the scraping process should be color coated for research inspection.

The ratio of the contact point area shown after the research is shown in the provisions of Table 3: or by 25mm × 25mm square area of the contact points are shown in the provisions of Table 3, and any 25mm × 25mm in between the contact points should not be greater than 5 points.

What is the T-slot bed plate production process?

First, T-slot bed plate blank: according to the technical requirements of the drawing, according to the drawing of the production of wood type, batching, modeling, drying, casting, falling sand, cleaning, and an inspection of all parts of the blank.

Second, cast iron plate machining: appearance inspection and scribing, processing, and inspection.

Third, cast iron plate workpiece leveling, manual scraping and research, and inspection section inspection.

Fourth is the appearance of cast iron plate processing, printing, packaging, and storage.

T-slot bed plate bearing requirements: cast iron plate bearing is the deformation deflection of the cast iron plate after the weight per unit area of the cast iron plate.

To facilitate understanding, we can see the cast iron plate put the workpiece, without affecting the normal use of the situation, the pressure the cast iron plate can withstand.

Notes

- There should be no rust, scratches, bruises, or other appearance defects on the working surface of the T-slot plate that affect its use.

- T-slot plate working surface should not have sand holes, pores, cracks, slag and shrinkage, and other casting defects. The casting surface should be thoroughly removed from the sand, and the surface should be smooth and painted firmly. The tax edge should be repaired bluntly.

- T-slot on the opposite sides of the surface of the plate. There should be installation handle or lifting position settings, threaded holes, or cylindrical holes. When setting the lifting position should be considered to minimize the deformation caused by lifting.

- T-slot plate should be processed by stability and demagnetization.

- T-slot plate working surface and the side and the adjacent sides of the vertical tolerance of 12 levels (according to GB1184-80 “shape and position tolerance”).

- T-slot plate working surface hardness should be between HB170-220 or 187-255.

- T-slot main calibration items

- Material and surface hardness.

- Shape and position tolerance, including nominal size and verticality tolerance.

- Appearance.

- Flatness.

- Contact spot.

- Plane-wave momentum.

- Allowable deflection value of the working surface.

- Surface roughness.

- Accuracy parameters.

3 level flat plate does not specify the contact spot requirements:

Level 1 plate requires a contact spot number in any 25 × 25mm plane not less than 20 points.

Level 2 plate requires a contact spot number in any 25 × 25mm plane not less than 12 points.

The T-slot floor plate platform will produce part of the theoretical weight deviation in the production process. It is important to note that the deviation of the cast iron plate is not affected by the use of the cast iron plate.

General cast iron plate design should consider casting and machining errors. Cast iron plate weight error generally shall not exceed 10% or more than 10%. We have to further identify the quality of cast iron plates to determine whether the cast iron plate can be put into use.

The T-slot bed plate production process will have some product defects as long as the correct method can be used to make up for the process. Cast iron plate working surface defects are important and can not be ignored. Cast iron plate defects include porosity, sand holes, sand trapping, shrinkage, etc. So the defects of the cast iron plate are to do repair in strict accordance with the process requirements.

Besides this What is T-slot Bed Plate article, you may also be interested in the below articles?

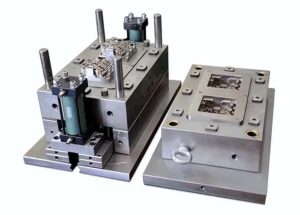

Summary Of 50 Injection Mold Structure Operation Dynamic Diagrams

Auto Parts Stamping Die Design Concept