- 86-17322110281

- [email protected]

- No.51 of Xida Rd Changan, Dongguan, China

The G 210 and G 2150 heavy-duty D-shackles for lifting are supplied by DGMF Mold Clamps Co., Ltd, the mold clamps Manufacturer in China, which also provides injection mold components, die press components, machine tools, and fasteners for your best choice.

Contact the DGMF sales team for the D-shackle specifications, pricing, and inventory.

Or the lifting element styles you need.

Please send us the item SKU# and the page link you are interested in to [email protected].

We will reply to you as soon as possible.

Heavy-duty D-Shackles for Lifting using high-quality alloy steel, die forging, and a free combination of manufacturing methods, shackles all heat-treated to ensure that the product’s impact resistance, load-bearing capacity, toughness, and elongation, greatly improving its safety and service life.

The dee shackle also known as a chain shackle, D-shackles are narrow shackles shaped like a loop of chains, usually with a pin or threaded pin closure. D-shackles are very common and most other shackle types are a variation of the D-shackle. The small loop can take high loads primarily in line. Side and racking loads may twist or bend a D-shackle.

High-strength Dee shackles are widely used in electric power, metallurgy, petroleum, machinery, railroads, chemical industries, ports, mines, construction, and other industries that require lifting.

The Heavy-duty D-Shackles for Lifting are the lifting Dee shackles supplied by DGMF Mold Clamps Co., Ltd for industrial lifting applications.

The pin is threaded and one leg of the shackle is tapped. The pin may be captive, which means it is mated to the shackle, usually with a wire. The threads may gall if overtightened or have been corroding in the salty air, so a liberal coating of lanolin or heavy grease is not out of place on any threads. A shackle key or metal marlinspike are useful tools for loosening a tight nut.

For safety, it is common to use a threaded shackle to keep the pin from coming loose. This is done by looping mousing wire or a nylon zip tie through the hole in the pin and around the shackle body. For pins that have a cross-hole in the threaded end, a cotter pin can be used.

Monolithic casting molding, strong and durable

Forged high carbon alloy steel, solid casting

Surface galvanized treatment, rust, and corrosion prevention

etc.

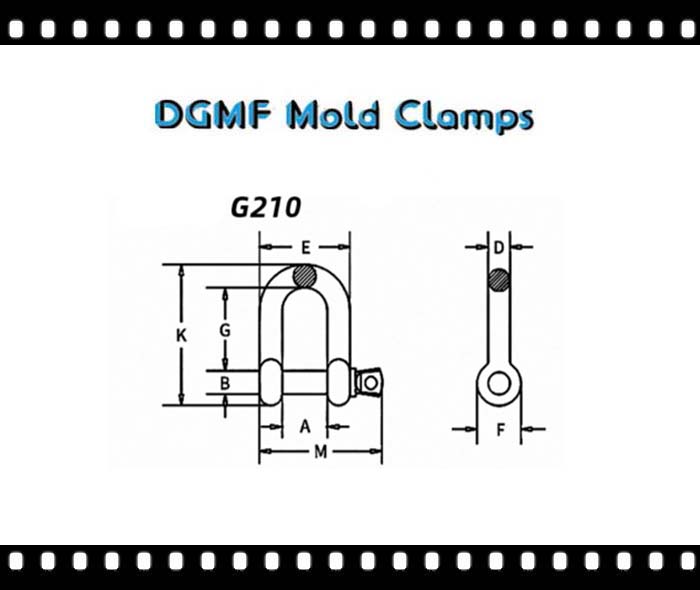

DGMF Metric G210 D-Shackle Specs |

|||||||||||

| SKU | Size | Loading | Weight | Dimension/MM | |||||||

| MM | T | KG | A | B | D | E | F | G | K | M | |

| DGMF-MOLD-CLAMPS-G210-6 | 6 | 0.5 | 0.05 | 12 | 7.9 | 6.4 | 23.9 | 15.5 | 22.4 | 40.4 | 35.1 |

| DGMF-MOLD-CLAMPS-G210-8 | 8 | 0.75 | 0.08 | 13.5 | 9.7 | 7.9 | 29.5 | 19.1 | 26.2 | 48.5 | 42.2 |

| DGMF-MOLD-CLAMPS-G210-10 | 10 | 1 | 0.13 | 16.8 | 11.2 | 11.2 | 35.8 | 23.1 | 31.8 | 58.4 | 51.6 |

| DGMF-MOLD-CLAMPS-G210-11 | 11 | 1.5 | 0.2 | 19.1 | 12.7 | 12.7 | 41.4 | 26.9 | 36.6 | 67.6 | 60.5 |

| DGMF-MOLD-CLAMPS-G210-13 | 13 | 2 | 0.27 | 20.6 | 16 | 16 | 45 | 30.2 | 41.4 | 77 | 68.3 |

| DGMF-MOLD-CLAMPS-G210-16 | 16 | 3.25 | 0.57 | 27 | 19 | 19 | 58.7 | 38.1 | 50.8 | 95.3 | 84.8 |

| DGMF-MOLD-CLAMPS-G210-19 | 19 | 4.75 | 1.19 | 31.8 | 22.4 | 22.4 | 69.9 | 46 | 60.5 | 115.1 | 100.8 |

| DGMF-MOLD-CLAMPS-G210-22 | 22 | 6.5 | 1.43 | 36.6 | 25.4 | 25.4 | 81 | 53.1 | 71.4 | 135.4 | 114.3 |

| DGMF-MOLD-CLAMPS-G210-25 | 25 | 8.5 | 2.15 | 43 | 28.7 | 28.7 | 93.7 | 60.5 | 81 | 150.9 | 128.8 |

| DGMF-MOLD-CLAMPS-G210-29 | 29 | 9.5 | 3.06 | 46 | 31.8 | 31.8 | 103.1 | 68.3 | 90.9 | 172.2 | 142 |

| DGMF-MOLD-CLAMPS-G210-32 | 32 | 12 | 4.11 | 51.6 | 35.1 | 35.1 | 115.1 | 76.2 | 100.1 | 190.5 | 156.5 |

| DGMF-MOLD-CLAMPS-G210-35 | 35 | 13.5 | 5.28 | 57.2 | 38.1 | 38.1 | 127 | 94.1 | 111.3 | 210.3 | 173.7 |

| DGMF-MOLD-CLAMPS-G210-38 | 38 | 17 | 7.23 | 60.5 | 41.4 | 41.4 | 136.6 | 91.9 | 122.2 | 230.3 | 186.7 |

| DGMF-MOLD-CLAMPS-G210-45 | 45 | 25 | 12.13 | 73.2 | 50.8 | 50.8 | 162.1 | 106.4 | 146.1 | 278.6 | 230.6 |

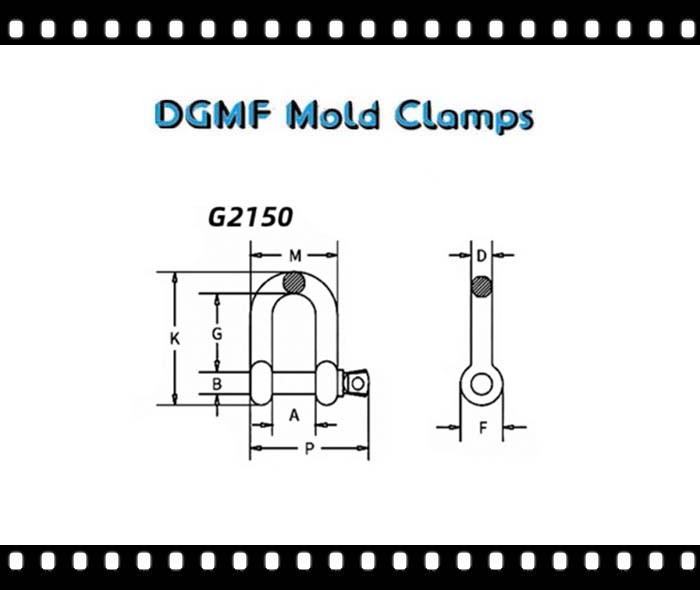

DGMF Inch G2150 D-Shackle Specs |

|||||||||||

| SKU | Size | Loading | Weight | Dimension/MM | |||||||

| IN | T | KG | A | B | D | F | G | K | M | P | |

| DGMF-MOLD-CLAMPS-G2150-1/2 | 1/2 | 2 | 0.34 | 20.6 | 16 | 12.7 | 30.2 | 41.4 | 77 | 46 | 71.1 |

| DGMF-MOLD-CLAMPS-G2150-5/8 | 5/8 | 3.25 | 0.67 | 26.9 | 19.1 | 16 | 38.1 | 50.8 | 95.3 | 58.7 | 89.7 |

| DGMF-MOLD-CLAMPS-G2150-3/4 | 3/4 | 4.75 | 1.14 | 31.8 | 22.4 | 19.1 | 45 | 60.5 | 115.1 | 70 | 103.4 |

| DGMF-MOLD-CLAMPS-G2150-7/8 | 7/8 | 6.5 | 1.75 | 36.6 | 25.4 | 22.4 | 53.1 | 71.4 | 135.4 | 81 | 119.6 |

| DGMF-MOLD-CLAMPS-G2150-1 | 1 | 8.5 | 2.52 | 42.9 | 28.7 | 25.4 | 60.5 | 81 | 150.9 | 93.7 | 134.9 |

| DGMF-MOLD-CLAMPS-G2150-1 1/8 | 1 1/8 | 9.5 | 3.45 | 46 | 31.8 | 28.7 | 68.3 | 90.9 | 172.2 | 103.1 | 149.9 |

| DGMF-MOLD-CLAMPS-G2150-1 1/4 | 1 1/4 | 12 | 4.9 | 51.6 | 35.1 | 31.8 | 76.2 | 100 | 190.5 | 115.1 | 165.4 |

| DGMF-MOLD-CLAMPS-G2150-1 3/8 | 1 3/8 | 13.5 | 6.24 | 57.2 | 38.1 | 35.1 | 84.1 | 111.3 | 210.3 | 127 | 183.1 |

| DGMF-MOLD-CLAMPS-G2150-1 1/2 | 1 1/2 | 17 | 8.39 | 60.5 | 41.4 | 38.1 | 92.2 | 122.2 | 230.1 | 136.7 | 196.3 |

| DGMF-MOLD-CLAMPS-G2150-1 3/4 | 1 3/4 | 25 | 14.24 | 73.2 | 50.8 | 44.5 | 106.4 | 146.1 | 278.6 | 162.1 | 229.8 |

| DGMF-MOLD-CLAMPS-G2150-2 | 2 | 32 | 21.2 | 82.6 | 57.2 | 50.8 | 122.2 | 171.5 | 311.9 | 184.2 | 264.4 |

| DGMF-MOLD-CLAMPS-G2150-2 1/2 | 2 1/2 | 55 | 38.56 | 104.9 | 70 | 66.5 | 144.5 | 203.2 | 377 | 238.3 | 344.4 |

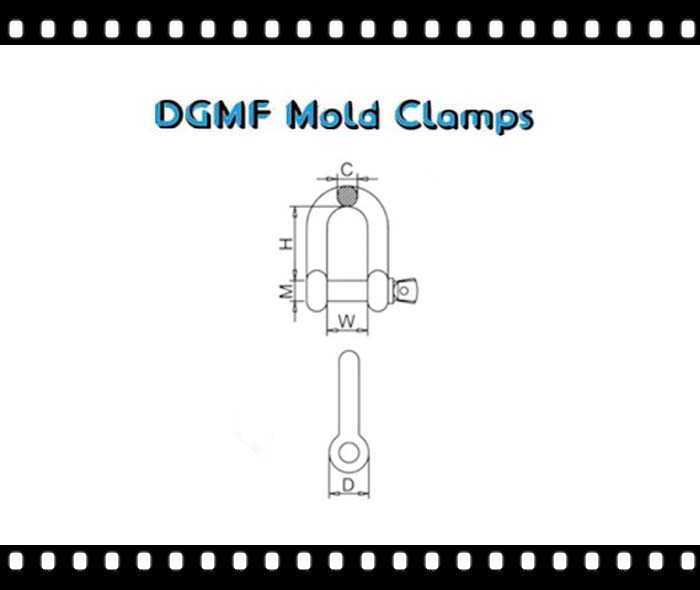

DGMF Stainless Steel Metric D-Shackle Specs |

|||||||

| SKU | Size | H | W | D | C | Loading | Weight |

| mm | mm | mm | mm | kg | kg | ||

| DGMF-MOLD-CLAMPS-LSDSS-4 | M4 | 16 | 8 | 9 | 4 | 120 | 0.008 |

| DGMF-MOLD-CLAMPS-LSDSS-5 | M5 | 19 | 10 | 11 | 5 | 200 | 0.045 |

| DGMF-MOLD-CLAMPS-LSDSS-6 | M6 | 22 | 12 | 12 | 6 | 300 | 0.024 |

| DGMF-MOLD-CLAMPS-LSDSS-8 | M8 | 30 | 16 | 16 | 8 | 500 | 0.058 |

| DGMF-MOLD-CLAMPS-LSDSS-10 | M10 | 39 | 21 | 20 | 10 | 800 | 0.111 |

| DGMF-MOLD-CLAMPS-LSDSS-12 | M12 | 49 | 25 | 24 | 12 | 1000 | 0.199 |

| DGMF-MOLD-CLAMPS-LSDSS-14 | M14 | 56 | 28 | 28 | 14 | 1500 | 0.318 |

| DGMF-MOLD-CLAMPS-LSDSS-16 | M16 | 66 | 33 | 32 | 16 | 2000 | 0.472 |

| DGMF-MOLD-CLAMPS-LSDSS-18 | M18 | 69 | 36 | 36 | 18 | 2500 | 0.648 |

| DGMF-MOLD-CLAMPS-LSDSS-20 | M20 | 74 | 42 | 40 | 20 | 3000 | 0.888 |

| DGMF-MOLD-CLAMPS-LSDSS-22 | M22 | 90 | 45 | 44 | 22 | 4000 | 1.222 |

| DGMF-MOLD-CLAMPS-LSDSS-25 | M25 | 100 | 54 | 50 | 25 | 5000 | 1.78 |

| DGMF-MOLD-CLAMPS-LSDSS-28 | M28 | 95 | 56 | 56 | 28 | 7000 | 2.288 |

| DGMF-MOLD-CLAMPS-LSDSS-32 | M32 | 102 | 64 | 64 | 32 | 8000 | 3.333 |

| DGMF-MOLD-CLAMPS-LSDSS-38 | M38 | 118 | 76 | 73 | 38 | 12000 | 5.612 |

1. Use shall not exceed the specified load, and should make the pin and shackle top force, lateral use will cause deformation of the shackle body.

2. Use the unloading shackle to tie up when lifting, lifting the object should make the top of the shackle in the upper, and the pin in the lower, so that the sling shackle pressure after the pressure of the pin, the pin because of the force, the pinhole in the friction so that the pin is not easy to come out.

3. Can not throw the shackle from a high place to down, to prevent the shackles landed on the collision and deformation or internal damage and cracks.

American standard shackles (G-209, G-210, G-2150, G-2130), alloy steel shackles, marine shackles, general use shackles, national standard shackles, Japanese-style shackles, and so on.