Description

What are Ejector Blades?

Ejector Blades also known as blade pin, mainly used for plastic products rib part of the ejection, there is a long plastic position, Round Ejector Pin cannot swing down, we choose to use an ejector blade, the blade pin is plastic mold accessories, used in a plastic mold.

A flat ejector blade pin can also be called push rod, blade pin, needle, supporting needle, and sometimes the lathe with the top is also called the ejector sleeve pin.

DIN Hardened Ejector Blades Product Discription

Blade thickness and width are held to close tolerance: +.0000/-.0003

Precision made of superior quality M2 high-speed tool steel

Through-hardened to 43-50 HRC for superior wear resistance

Heads annealed for easy machining

One-piece construction for increased strength and rigidity

Material: SKD61 Hotwork Die Steel

Ejector Blades Features

1. The diameters are a wide variety of shank and blade combinations.

2. Head hot forged, shaft hardens, and ground.

3. Particularly suitable for plastic molds.

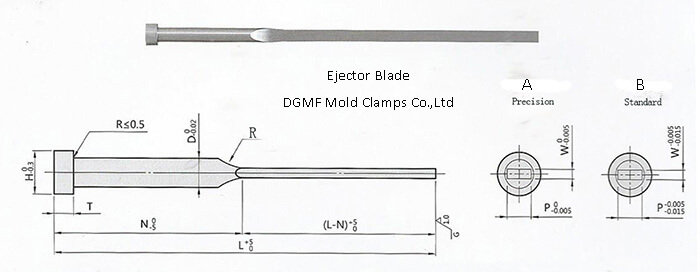

4. The hot-forged pinheads are precision ground and partially annealed from the automatic annealing machine(AAM).Ejector Blades drawing:

Blade Hardness: 43-50 HRC

| Molder Number | D | H | T | H | T | L 0.01mm | P 0.01mm | W 0.01mm | N 1mm | |

| Head Thickness | Standard Head | |||||||||

| DGMF-009-A (T-0.02) | DGMF-009-B (T-0.05) | 1.5 2.0 | 3 | 4 | 3 | 4 | 40.0-250.0 | 0.50-1.30 | 0.30- | N≥30 |

| 4 | 4 | 40.0-300.0 | 0.80-1.80 | |||||||

| 2.5 3.0 | 5 | 5 | 0.80-2.30 | |||||||

| 6 | 6 | 40.0-350.0 | 0.80-2.80 | |||||||

| 3.5 | 7 | 7 | 1.00-3.30 | |||||||

| 4.0 | 8 | 6 | 1.00-3.80 | |||||||

| 4.5 | 8 | 1.20-4.30 | ||||||||

| 5.0 | 9 | 50.0-350.0 | 1.50-4.80 | 0.40- | ||||||

| 5.5 | 9 | 1.80-5.30 | ||||||||

| 6.0 | 10 | 2.00-5.80 | 0.50- | |||||||

| 6.5 | 10 | 11 | 2.00-6.30 | |||||||

| 7.0 | 2.30-6.80 | |||||||||

| 8.0 | 11 | 13 | 8 | 2.30-7.80 | ||||||

| 8.5 | 14 | 14 | 2.30-8.30 | |||||||

| 10.0 | 15 | 15 | 3.00-9.80 | |||||||

| 10.5 | 17 | 17 | 3.00-10.30 | |||||||

| 12.0 | 3.50-11.80 | 0.80- | ||||||||

| – | 15.0 | – | – | 20 | 3.50-14.80 | 1.00- | ||||

TO ORDER SPECIFY: Model Number-D-L-P-W-N-H-T

Ejector Pins

The ejector pins and the ejector sleeves are called the ejector pin sleeve pin assembly, which is one of the plastic mold accessories. The ejector pin is the ejector sleeve in the ejector sleeve pin assembly.

The ejector pin sleeve pin is a metal rod used to eject the rubber product manufactured by the rubber position. The product is continuously ejected in the high-speed mold, and the telescopic movement of the cylinder is used for wear or processing.

The ejector pin sleeve pin generally uses a harder metal as the material, such as SKH51, which has a hardness of 58-60HRC. The cylinder ejector pin made of high-quality high-speed steel has a beautiful metallic luster. The production process of an ejector pin sleeve is similar to that of an ejector pin. The structure size of the ejector sleeve is very different from that of the ejector pin, and the size of the large head generally has an irregular size.

When the ejector sleeve is produced, it is generally necessary to spray an anti-rust agent to prevent rust. During use, if the mold is idle for a long time, attention should be paid to rust prevention.

After nitriding treatment, the ejector pin has the characteristics of wear resistance, durable hot work mold steel, and can withstand high temperatures above 1200 degrees.

At present, the ejector pin sleeve pin technology manufactured by China’s mold components factories has reached international standards.

DGMF Mold Clamps Co., Ltd supplies the ejector pins, straight ejector pins, ejector sleeve pins, ejector blades, shoulder ejector pins, guide pins, core pins, angle pins, dowel pins, guide bushing, A-type sprue bushing, B-type sprue bushing, C-type sprue bushing, small gate sprue bushing, big gate sprue bushing, etc.

Contact the DGMF team for the injection mold components specification, inventory, pricing.

Reviews

There are no reviews yet.