Description

What are Latch Locking Units?

The latch locking unit is a kind of clamping device, which is used to fix the die mold. It is widely used in stamping molds, die-casting molds, automotive parts, and equipment manufacturing industries. There are certain requirements for the material selection and processing technology of the mold clamping buckle.

Noted: The latch lock device design is simple, easy to install, and highly reliable in operation.

Latch locking units are used primarily on injection molds with multiple plate movements. They can be subject to particularly high loads as a function of the component dimensions and the size of the mold.

With its extensive range of latch-locking units, DGMF offers a variety of options for solving complex applications on a customized basis.

Latch locking units include lock devices Z170/, Z171/, Z173, and Z174/…, which now have a DLC coating on their functional surfaces, which is said to keep friction and wear down to a minimum. They are especially suited to use in the food and medical sectors, since production can be run without lubricants, making it compatible with a cleanroom environment.

The coating does not lead to any dimensional changes in the functional surfaces, hence the new latch locking units can be fitted 1:1 to existing systems. The latch locking units show good slip properties, due to the low coefficients of friction, and show high corrosion protection.

Tested and tested with Z171 can be used in two.

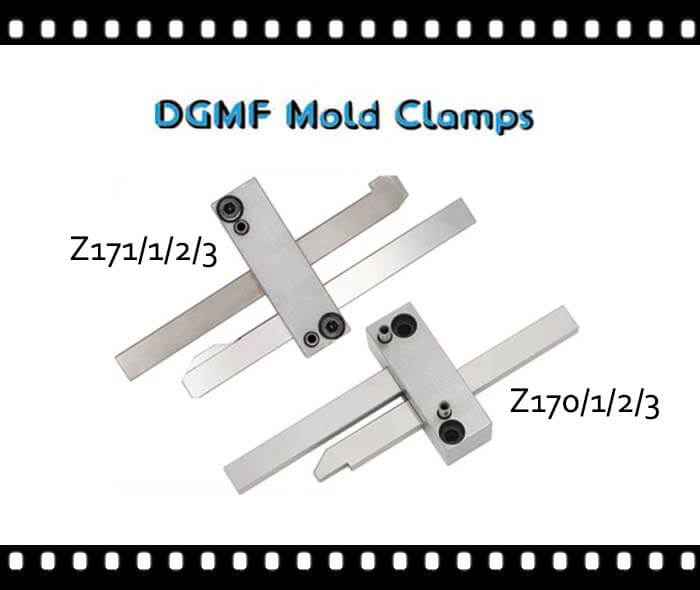

Latch Locking Units Pictures

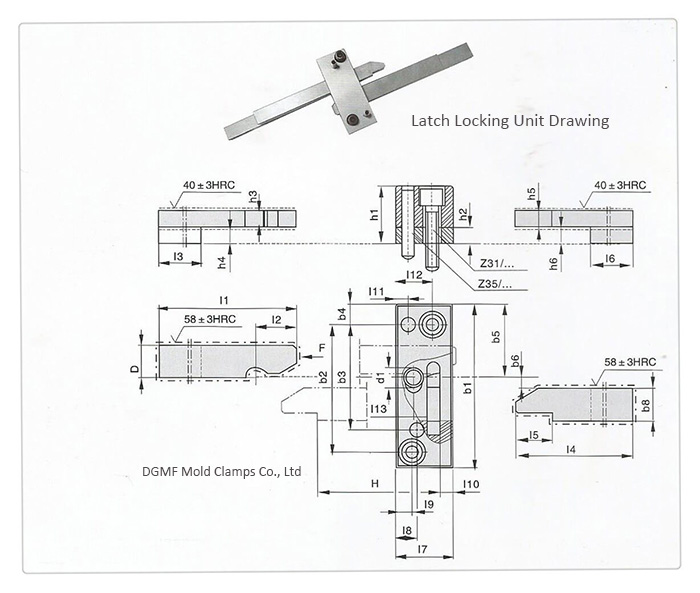

The Latch Locking Unit Drawing

The Z170/1/2/3 Latch Locking Units Specifications

| Latch Lock Model Number | Type | b1 | I7 | b4 | I11 | I9 | I8 | I12 | b5 | I13 | h2 | I1 | b7 | h3 | I4 |

| DGMF-MOLD-CLAMPS-082-Z170 | Z170/1 | 63 | 22 | 8 | 5 | 6 | 8 | 14 | 28.5 | 7 | 6 | 100 | 12.5 | 6 | 125 |

| Z170/2 | 90 | 34 | 13 | 8 | 8 | 18 | 24 | 45 | 16 | 7.5 | 140 | 20 | 12.5 | 160 | |

| Z170/3 | 110 | 42 | 15 | 9 | 9 | 22 | 31 | 55 | 20 | 12 | 200 | 25 | 16 | 250 |

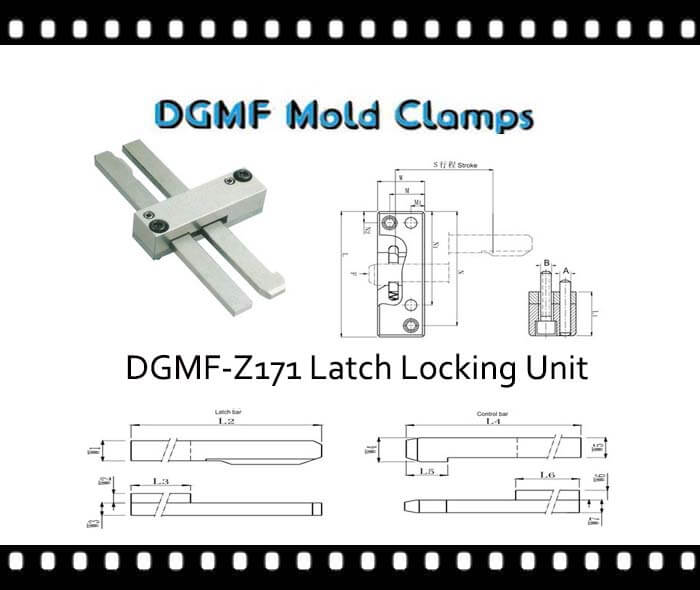

Z171/1/2/3 latch lock device specifications

| Latch Lock Model Number | Type | L | L1 | L2 | L3 | L4 | L5 | L6 | M | M1 | N | N1 | N2 | W | W1 | W2 | W3 | W4 | W5 | W6 | W7 | A | B |

| DGMF-MOLD-CLAMPS-082-Z171 | Z171/1 | 75 | 22 | 140 | 63 | 140 | 12 | 63 | 16 | 6 | 69 | 60 | 6 | 22 | 13 | 6.5 | 6 | 16 | 13 | 6.5 | 6 | 5 | M5 |

| DGMF-MOLD-CLAMPS-082-Z172 | Z171/2 | 90 | 32.5 | 180 | 100 | 180 | 16 | 100 | 24 | 8 | 83 | 73 | 7 | 31.5 | 16 | 8 | 13 | 20.5 | 16 | 8 | 12.5 | 6 | M6 |

| DGMF-MOLD-CLAMPS-082-Z173 | Z171/3 | 112 | 43.5 | 250 | 125 | 250 | 20 | 125 | 30 | 10 | 103 | 88 | 9 | 40 | 20 | 12.5 | 16 | 25.5 | 20 | 12.5 | 16 | 8 | M8 |

| Latch Lock Model Number | Type | Stroke(min.) | Stroke(max.) | Pulling force(≦kgf) |

| DGMF-MOLD-CLAMPS-082-Z171 | Z171/1 | 5.5 | 80 | 650 |

| DGMF-MOLD-CLAMPS-082-Z172 | Z171/2 | 7 | 110 | 1550 |

| DGMF-MOLD-CLAMPS-082-Z173 | Z171/3 | 9 | 160 | 2200 |

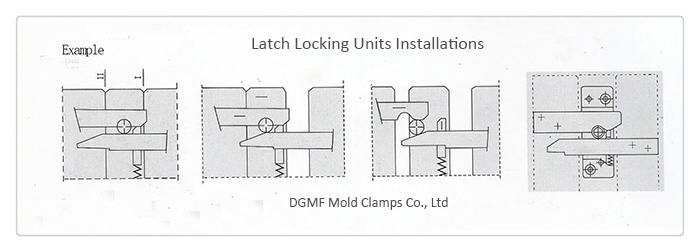

Latch Locking Units installation

The latch locking unit is used to fix the AB plate, and will not open the first time, preventing the mold from moving, which can play a role in setting and protection.

The characteristics of the Latch Locking Units

- Mold material: mold steel

- Dimensional accuracy: accuracy can reach ±0.002mm, total length accuracy can reach ±0.003mm

- Product hardness: high-temperature quenching: hardness HRC59 ° -61 °

- The product features high hardness, good toughness, and excellent wear resistance.

- Manufacturing process: car/milling/grinding/CNC deep hole drilling/round grinding/punch/line cutting/discharge

- Surface treatment: polished/titanium coated/blackened

- Product use: The service life is greatly improved, and it is suitable for molds in a high-temperature working environment.

The mechanical interlock design is safe and reliable; this Latch Locking Unit Z170 not only has the function of controlling the mold opening sequence but also can control the order of clamping; the tail end of the plunger adopts high-frequency annealing treatment to facilitate the secondary processing of the mounting hole.

MISUMI standard: PLS PLM PLL MPLK MLK MLKC latch locks

During the closing and opening of injection molds, the requirements for a snap-off machine are accurate and reliable, with low noise and impact.

The MISUMI standard Latch Locks PLS/PLM/PLL is a high-performance latch consisting of 7 parts (excluding screws and locating pins) and is characterized by: Compact and small size of the latch.

Accurate mold opening sequence with no reaction forces. There is no clamping load at all and it can be applied to low-pressure clamping molding. Its action has nothing to do with the mold closing sequence. If the runner push plate closes before the parting surface, the clamping block will retract by itself, so there is no need to worry about interference.

Usage of MISUMI standard Latch Locks

When using, it is important to note that these machines should be used in pairs and installed symmetrically. Two or four sets are commonly used.

PLS is suitable for molds up to 1.0 tonne with 2 sets installed; PLM is suitable for molds up to 1.8 tonne with 2 sets installed; PLL is suitable for molds up to 4.0 tonne with 2 sets installed.

Buy plastic mold component latch locks

Finding the right plastic mold component latch locks at DGMF Mold Clamps Co., Ltd. We have a series of plastic mold component latch locks as the below for your best choice.

HASCO Standard: Z170 Z171 Z174 Z173 latch locks

PUNCH standard: TYPE-S TYPE-F latch locks

STRACK standard: Z3 Z4 Z5 Z6 Z7 latch locks

DME standard: KU KL DKL latch locks

RABOURDIN standard: REP460 latch locks

PROGRESSIVE Standard: RPL latch locks

CUMSA Standard: GS latch locks

Taiwan Standard: DTP03 DTP04 DTP05 DTP06 DTP07 DTP08 latch locks

etc.

Contact the DGMF Mold Clamps sales team for more plastic mold component latch lock details suck as latch locks for injection molding styles, injection molding latch lock specifications, and injection molding latch lock inventory.

Or other mold components you need.

Reviews

There are no reviews yet.