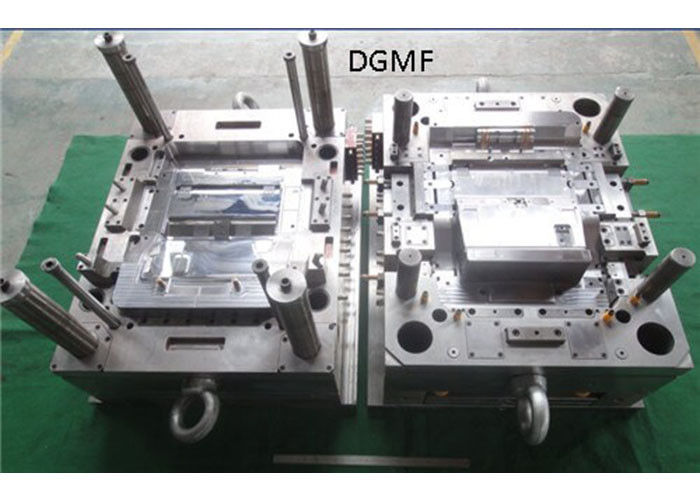

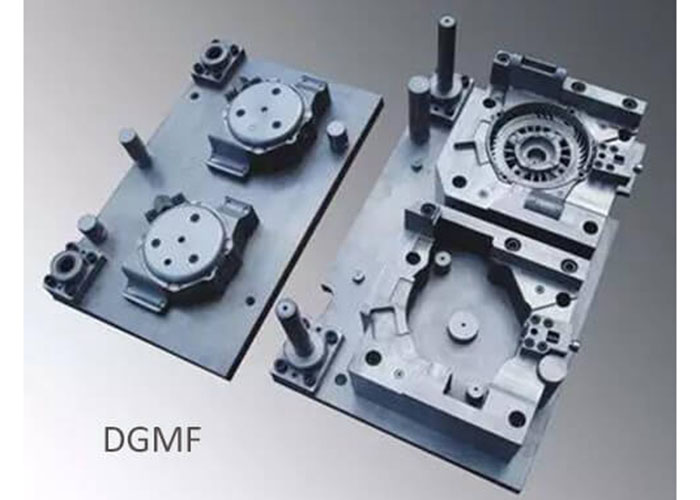

Molds Overview

After reading the Molds Overview article. You will know about Various molds and molding tools. Various molds and molding tools Molds, various molds, and tools used in industrial production to obtain the required products by injection molding blow molding, extrusion, die casting or forging, smelting, stamping, and other methods. In short, a mold is a […]

What is An Injection Molding?

Injection molding meaning What is an injection molding? Injection molding is an injection and molding method. Injection molding is a manufacturing process for producing parts by injecting molten material into a mould, or mold. The advantages of the injection molding method are fast production speed, high efficiency, the operation can be automated, a variety of […]

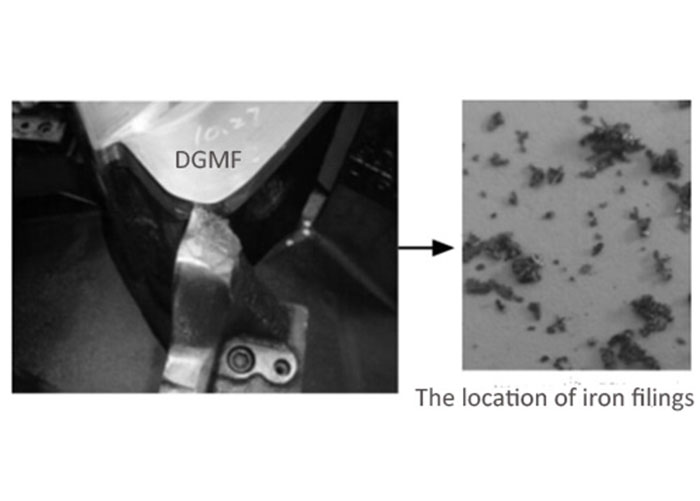

How To Solve The Iron Filings Produced By Stamping Die?

Why need to solve the iron filings produced by stamping die? In the production process of stamping parts, the main problems that affect the production pass rate are high points and pits, which directly cause the rework of the parts, increasing labor and energy consumption costs. And how to solve the iron filings produced by […]

How To Solve The Defect In The Product Gate Area?

After reading this How To Solve The Defect In The Product Gate Area article. You will get the answer to solve the defect in the product gate area. Solve The Defect In The Product Gate Area 1. Ray line Cause In the design of the point gate perpendicular to the direction of the injection molded […]

What is an Overmold?

After the read, you will learn about: What is an overmold? The difference between plastic over mold and two-color mold What are the problems that easily occur in the molding process With the continuous improvement of living standards, the requirements for materials and aesthetics are also continuously improved. More and more manufacturers choose the multi-color […]

How To Make A Silicone Rubber Mold?

After the read of this How To Make A Silicone Rubber Mold article. You will know the silicone rubber mold manufacturing method and precautions How To Make A Silicone Rubber Mold 1. Silicone rubber mold manufacturing method and precautions The silicone rubber mold is one of the simplest methods in rapid mold. Generally, the RP […]

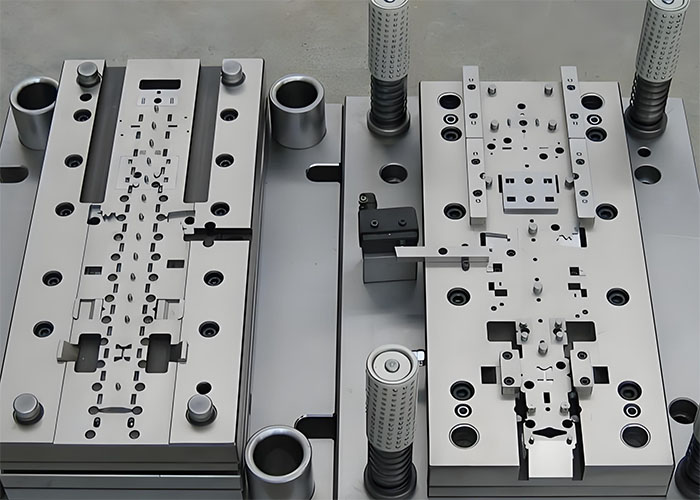

How To Install The Stamping Die?

After the read of how to install the stamping die article. You will know the correct way to install and remove the die molds. Install the stamping die – Mold installation and removal The installation and disassembly of the mold is a very critical skill of a stamping worker. It basically uses all the operations […]

How To Improve The Mold Trial Success Rate?

After reading the article. You will learn about: Why do we need to improve the mold trial success rate? How to improve the mold trial success rate? Why do we need to improve the mold trial success rate? First, mold designers and manufacturing technicians sometimes make mistakes. If we are not alert when we do […]

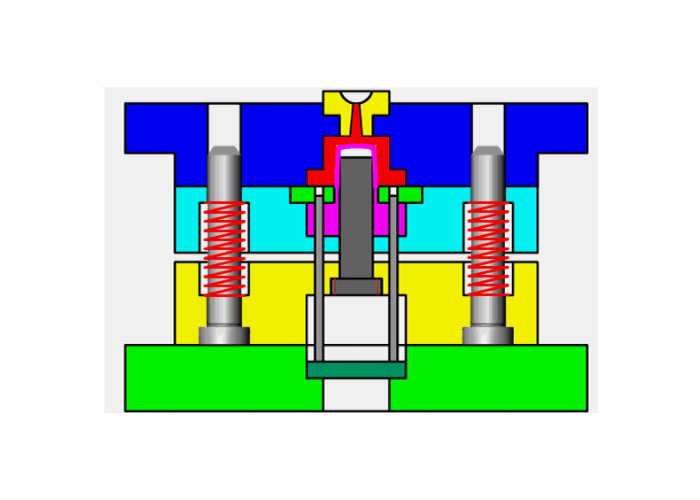

Summary of 50 Injection Mold Structure Operation Dynamic Diagrams

Molds play an important role in the industry, and a large number of industrialized products are inseparable from molds. Regardless of all walks of life, it is inevitable to deal with molds, so it is very meaningful to be familiar with and understand the structural principles of various common molds. I have sorted out 50 […]

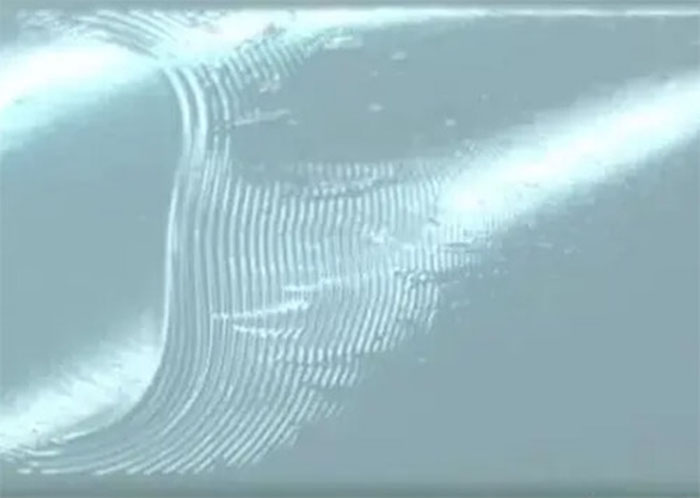

How to Solve Flow Lines in Injection Molded Products?

This article talks about the Analysis and countermeasures of flow lines in injection molded products. Analysis and countermeasures of flow lines in injection molded products Classification of flow lines in injection molded products 1) Snake lines When the melt enters the mold cavity from the gate, it produces a jet effect and appears on the surface […]